IA WARNING]

Remove the plug from the power source before assembly, changing accessories or cutters and making adjustments. This safety action will help prevent accidental starting of the tool which could result in serious injury.

OH I OFF & SPEED CONTROL SWITCHES

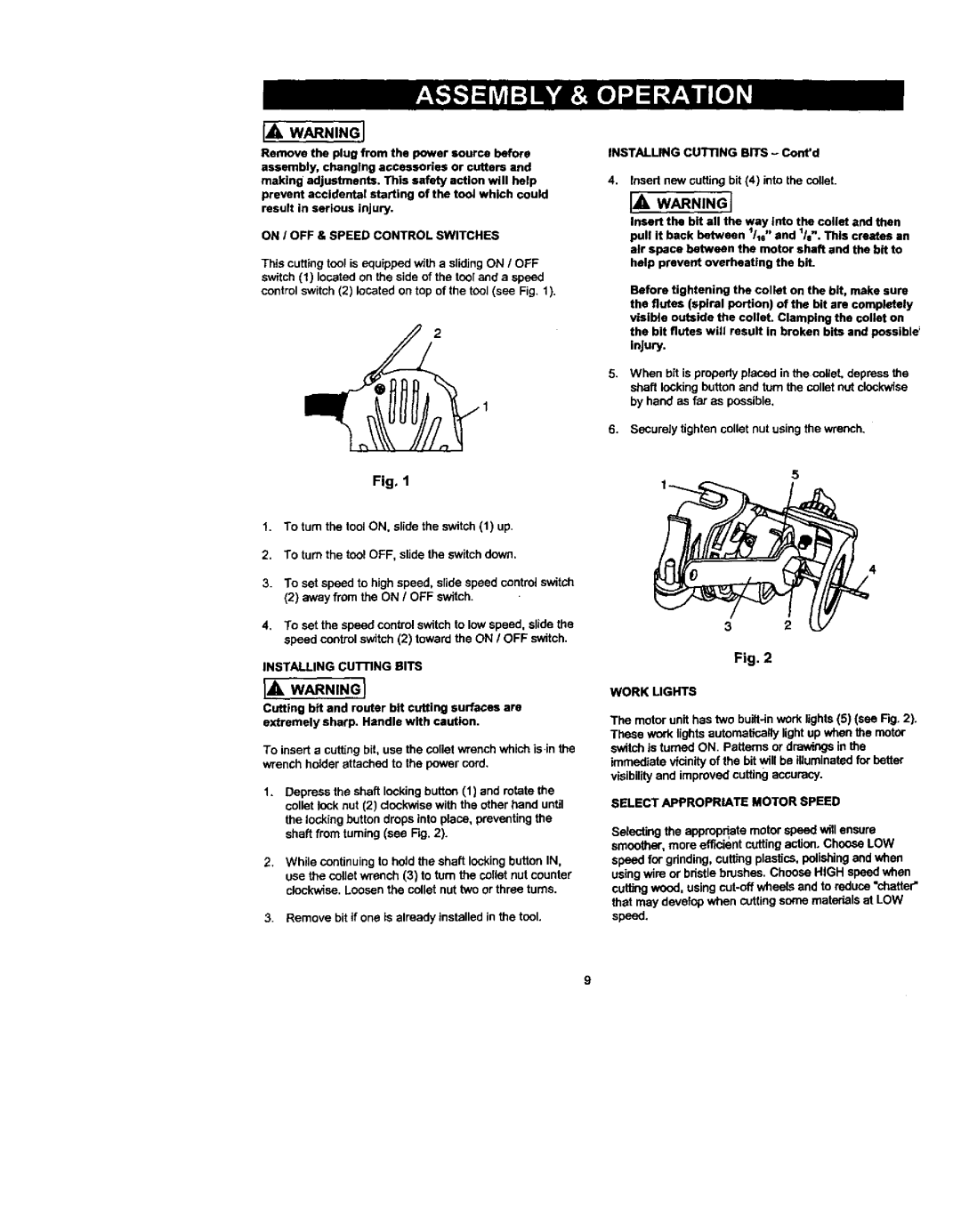

This cutting tool is equipped with a sliding ON / OFF switch (1) located on the side of the tool and a speed control switch (2) located on top of the tool (see Fig. 1).

INSTALLING CUTRNG BITS - Cont'd

4.Insed new cutting bit (4) into the collet.

IA WARNING I

Insert the bit all the way into the cohet and then pull it back between t/t0" and l/e", This creates an

air space between the motor shaft end the hit to help prevent overheating the bit.

Before tightening the collet on the bit, make sure the flutes (spiral portion) of the bit ere completely visible outside the catfat. Clamping the coltst on the bit flutes will result in broken bits and possible _ injury.

5, When hit is propedy placed in the collet, depress the shaft locking button and turn the collet nut clockwise by hand as far as possible,

6.Securely tighten collet nut using the wrench.

Fig. 1

1.TO turn the toot ON, slide the switch (1) up.

2.To turn the tool OFF, slide the switch down,

3.To set speedto highspeed,slidespeedcontrolswitch

(2) awayfromthe ON / OFF switch.

4.To set the speed control switch to low speed, slide the speed control switch (2) toward the ON / OFF switch.

INSTALLING CUTtiNG BITS

iA WARNING I

Cutting bit and router bit cutting surfaces are extremely sharp. Handle with caution.

To insert a cuffing bit, use the collet wrench which is.in the wrench holder attached to the power cord.

1.Deprese the shaft locking bufton (1} and mtste the collet lock nut (2) clockwise with the other hand until the locking button drops into place, preventing the shaft from turning (see Fig, 2).

2.While continuing to hold the shaft locking button IN, use the coflet wrench (3) to rum the collet nut counter clockwise. Loosen the collet nut two or three turns.

3.Remove bit if one is already installed in the tool.

4

32

Fig. 2

WORK LIGHTS

The motor unit has two

SELECT APPROPRIATE MOTOR SPEED

Selecting the appropriate motor speed will ensure smoother, more efficient cutting action. Choose LOW

speed for grinding, cuffing plastics, polishing and when using wire or bristle brushes. Cheese HIGH speed when cutting wood. using