i-:[l_l._][a] _1 -"r:1_isis

INSTALLING PRECISION HANDLE

The precision handle is designed for use when precision control over the tool movement is desired. The

comfodabie handle can be used with either the dght or left hand.

1.Slide precision handle mounting bracket (1) onto the bottom of motor housing (2) unffi the slot under the handle (3) lines up with the shaft tocking button (4) in

the motor housing (son Fig. 10).

NOTES:

a)The mounting bracket must be pushed onto the motor housing as far as it will go.

b)The shaft locking button (5) can now be activated by your thumb while holding on to the precision handle

2.Lock the predsion handle to the motor housing by snapping the quick locking lever (6) firmly against the motor housing.

Fig. 10

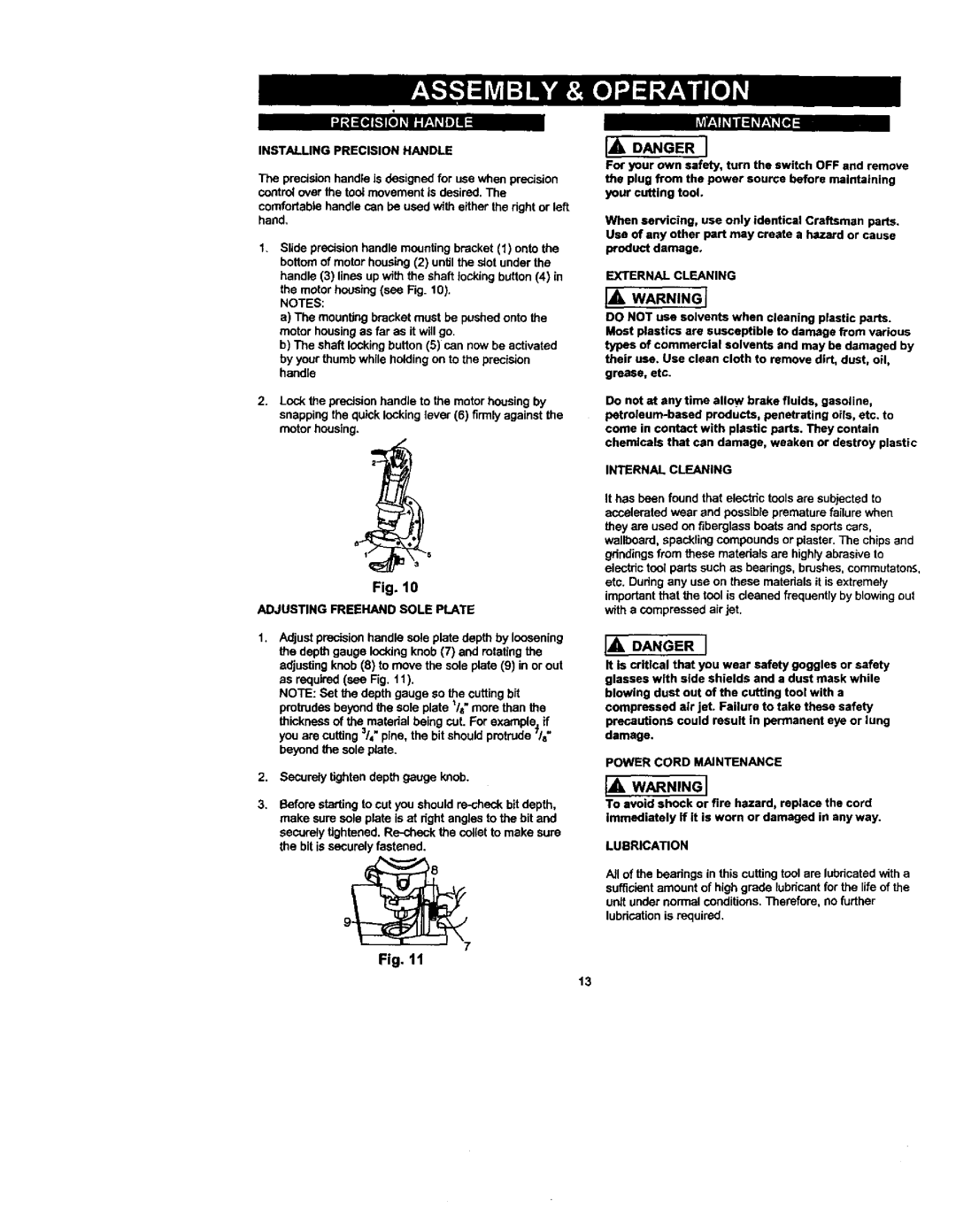

ADJUSTING FREEHAND SOLE PLATE

1.Adjust precision handle sole plate depth by loosening the depth gauge locking knob (7) and rotating the adjusting knob (8) to move the sole plate (9) in or out as required (see Fig. 11).

NOTE: Set the depth gauge so the cutting bit protrudes beyond the sole plate _/a"more than the thickness of the material being cuL For example if you are cutting 3/4"pine, the bit should pm_Jde fiB" beyond the sole plate.

2.Securely tighten depth gauge knob.

3.Before starting to cut you should recheck bit depth, make sure sole plate is at right angles to the bit and securely tightened.

I,_. DANGER I

For your own safety, turn the switch OFF and remove

the plug from the power source before maintaining your cutting tool.

When servicing, use only identical Craftsman ports.

Use of any other part may create a hazard or cause product damage,

EXTERNAL CLEANING

IA W NINGJ

DO NOT use solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloth to remove dirt, dust, oil, grease, atc.

Do not at any time allow brake fluids, gasoline,

INTERNAL CLEANING

It has bonn found that electdc tools are subjected to accelerated wear and possible premature failure when they are used on fiberglass boats and sports cars, wallboard, spackling compounds or plaster. The chips and gdndings from these materials are highly abrasive to electric tool parts such as beadngs, brushes, commutaton_, etc. Dudng any use on these materials it is extremely important that the tool is cleaned frequently by blowing out with a compressed air jet.

I_, DANGER ]

It Is critical that you wear safety goggles or safety glasses with side shields and a dust mask while blowing dust out of the cutting tool with a compressed air jet. Failure to take these safety precautions could result in permanent eye or lung damage.

POWER CORD MAINTENANCE

I_h, WARNINGJ

To avoid shock or fire hazard, replace the cord immediately if it is worn or damaged in any way.

LUBRICATION

A_Iof the bearings in this cuffing tool are lubdcated with a sufficient amount of high grade lubricant for the life of the unit under normal conditions. Therefore, no further lubrication is required.

Fig. 11

13