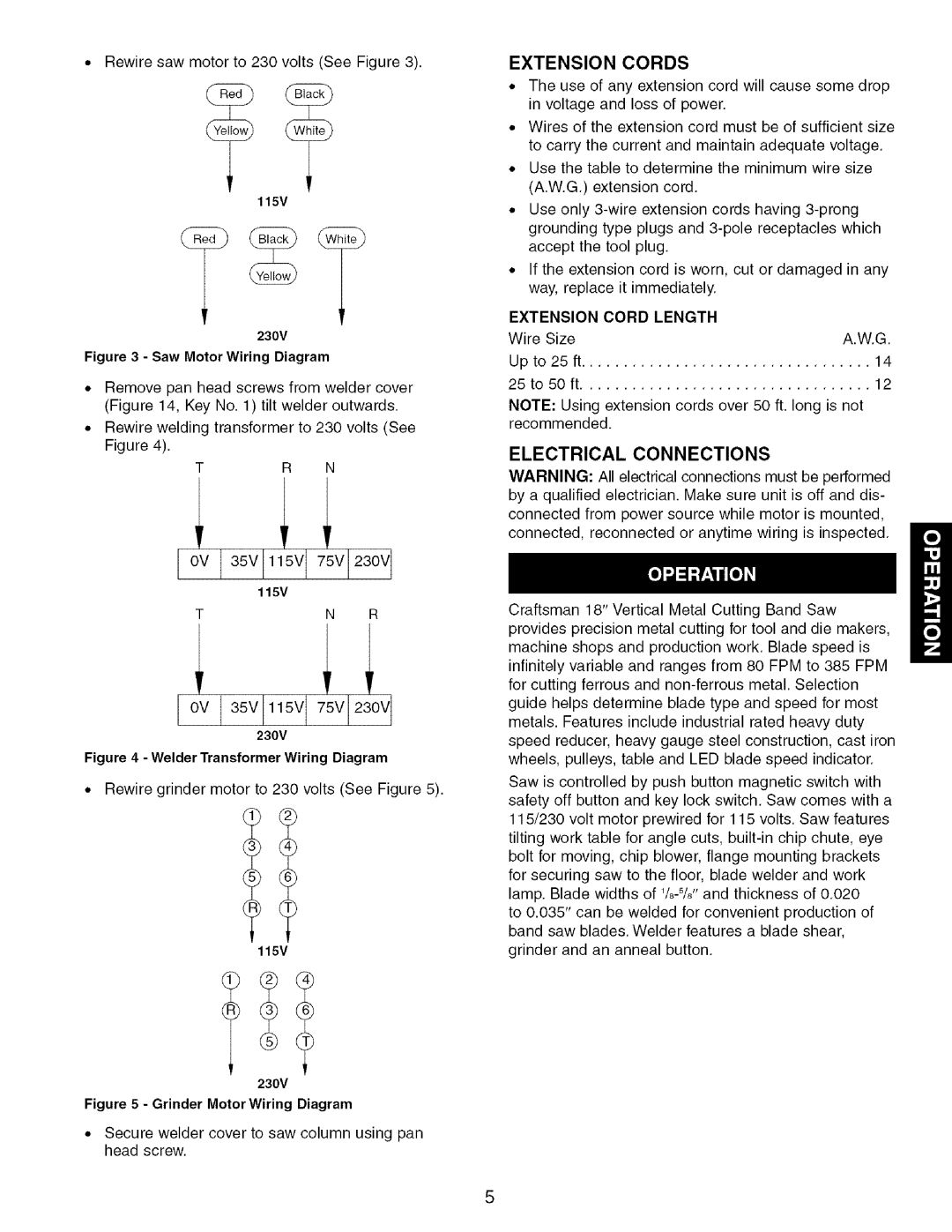

Rewire saw motor to 230 volts (See Figure 3).

115V

230V

Figure 3 - Saw Motor Wiring Diagram

•Remove pan head screws from welder cover (Figure 14, Key No. 1) tilt welder outwards.

•Rewire welding transformer to 230 volts (See Figure 4).

R N

Cv 35V 1 V V 230V

115V

N R

C 35V 115V V 2 V

230V

Figure 4 - Welder Transformer Wiring Diagram

•Rewire grinder motor to 230 volts (See Figure 5).

115V

230V

Figure 5 - Grinder Motor Wiring Diagram

•Secure welder cover to saw column using pan head screw.

EXTENSION CORDS

•The use of any extension cord will cause some drop in voltage and loss of power.

•Wires of the extension cord must be of sufficient size to carry the current and maintain adequate voltage.

•Use the table to determine the minimum wire size (A.W.G.) extension cord.

•Use only

•If the extension cord is worn, cut or damaged in any way, replace it immediately.

EXTENSION CORD LENGTH | |

Wire Size | A.W.G. |

Up to 25 ft | 14 |

25 to 50 ft | 12 |

NOTE: Using extension cords over 50 ft. long is not | |

recommended. |

|

ELECTRICAL | CONNECTIONS |

WARNING: All electrical connections must be performed | |

by a qualified electrician. Make sure unit is off and dis- | |

connected from power source while motor is mounted, | |

connected, reconnected or anytime wiring is inspected. | |

Craftsman 18" Vertical Metal Cutting Band Saw provides precision metal cutting for tool and die makers, machine shops and production work. Blade speed is infinitely variable and ranges from 80 FPM to 385 FPM for cutting ferrous and

to 0.035" can be welded for convenient production of band saw blades. Welder features a blade shear, grinder and an anneal button.