Refer to Figure 3.

WARNING: Make certain that the saw is disconnected from the power source before attempting to service or remove any component.

For proper maintenance:

•Keep saw clean. Sweep off spots where dust has collected.

•Clean the lead screw (Key No. 41), lead nut (Key No.

39)and pivot (Key No. 40) if vise action becomes difficult.

•Replace clogged and chipped abrasive wheels. A clean saw with a clean abrasive wheel will yield the best cut.

WARNING: Any attempt to repair the motor may

create a hazard unless repair is done by qualified service technician.

If motor becomes hot or sparks are seen through the vent slots, unscrew brush cap and check brushes (Key Nos. 4 and 5) for wear and dirt. Clean or replace when worn to '/,"long. Reinstall by aligning brush with slot. Secure with cap.

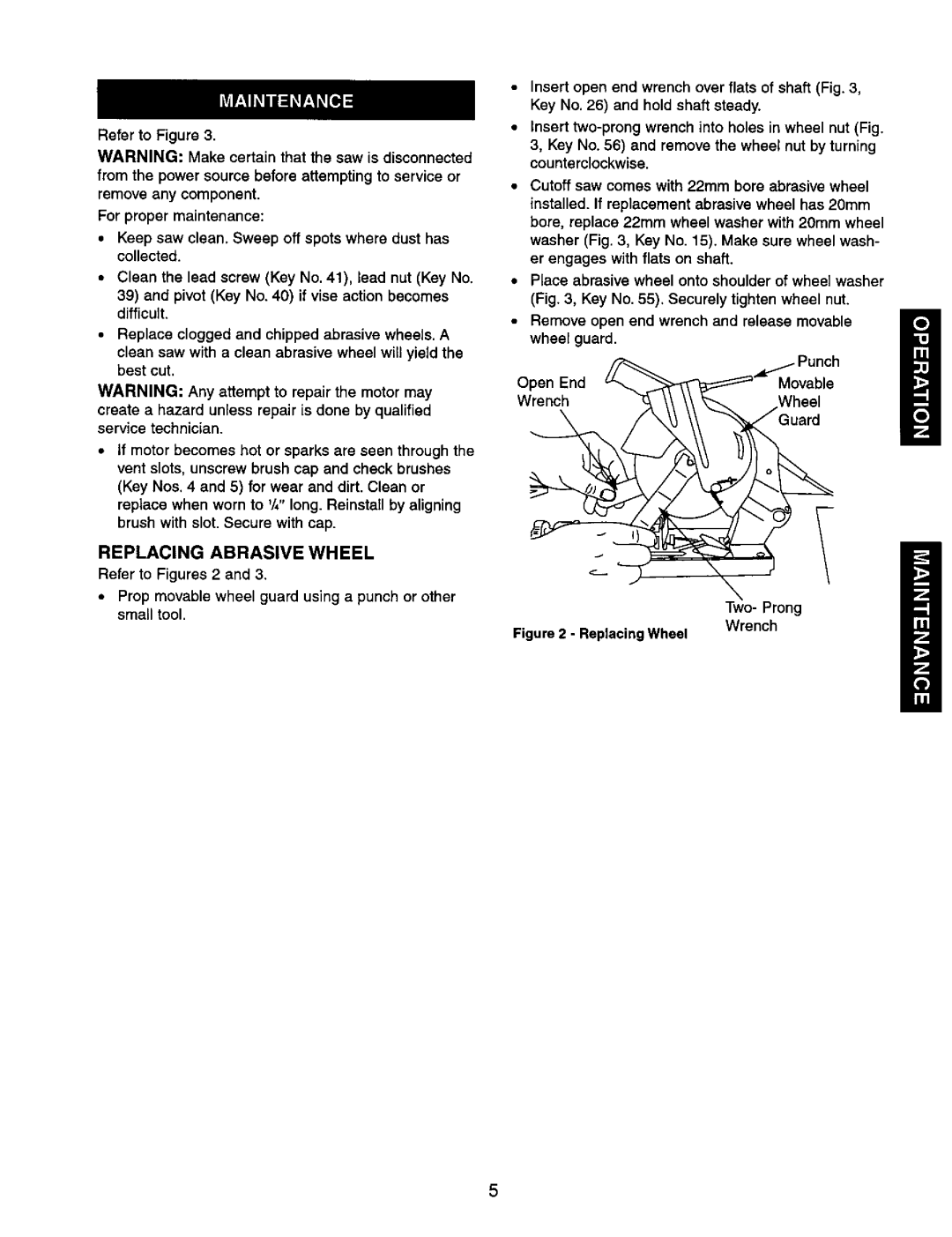

REPLACING ABRASIVE WHEEL

Refer to Figures 2 and 3.

•Prop movable wheel guard using a punch or other small tool.

•Insert open end wrench over flats of shaft (Fig. 3, Key No. 26) and hold shaft steady.

•Insert

3, Key No. 56) and remove the wheel nut by turning counterclockwise.

•Cutoff saw comes with 22ram bore abrasive wheel installed. If replacement abrasive wheel has 20mm bore, replace 22mm wheel washer with 20mm wheel washer (Fig. 3, Key No. 15). Make sure wheel wash- er engages with flats on shaft.

•Place abrasive wheel onto shoulder of wheel washer (Fig. 3, Key No. 55). Securely tighten wheel nut.

•Remove open end wrench and release movable wheel guard.

Open End | Movable |

Wrench |

|

Two- Prong

Wrench