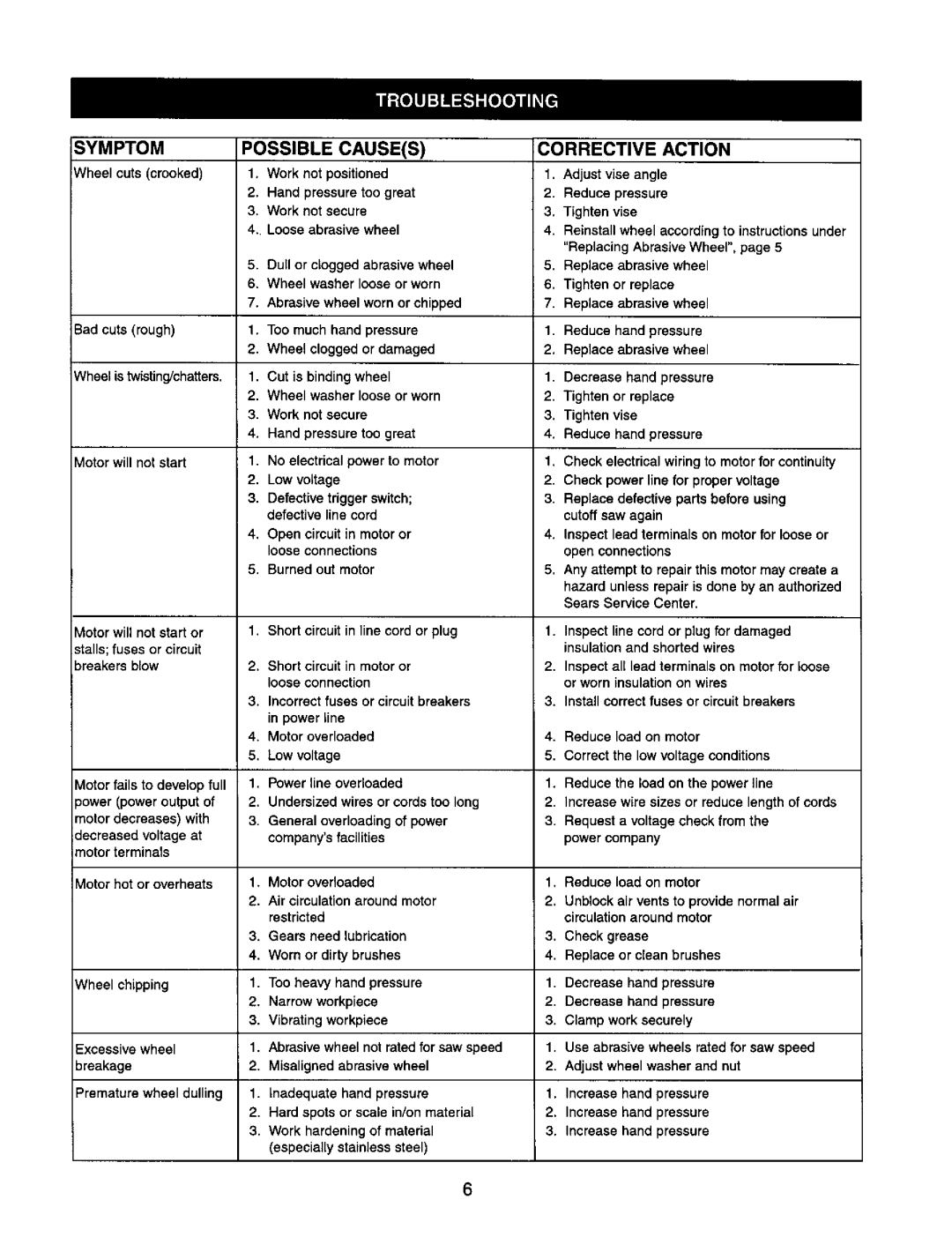

SYMPTOMPOSSIBLE CAUSE(S)

Wheel cuts (crooked) | 1. Work not positioned |

2.Hand pressure too great

3.Work not secure

4.Loose abrasive wheel

5.Dull or clogged abrasive wheel

6.Wheel washer loose or worn

7.Abrasive wheel worn or chipped

Bad cuts (rough) | 1. | Too much hand pressure | ||

| 2. | Wheel clogged | or damaged | |

Wheel is twisting/chatters. | 1. | Cut is binding | wheel | |

| 2. | Wheel washer | loose or worn | |

| 3. | Work not secure | ||

| 4. | Hand pressure too great | ||

Motor will not start | 1, | No electrical power to motor | ||

| 2. | Low voltage |

| |

| 3. | Defective | trigger switch; | |

|

| defective | line cord | |

| 4. | Open circuit in motor or | ||

|

| loose connections | ||

| 5. | Burned out motor | ||

CORRECTIVE ACTION

1.Adjust vise angle

2.Reduce pressure

3.Tighten vise

4.Reinstall wheel according to instructionsunder "Replacing Abrasive Wheel", page 5

5.Replace abrasive wheel

6.Tighten or replace

7.Replace abrasive wheel

1.Reduce hand pressure

2.Replace abrasive wheel

1.Decrease hand pressure

2.Tighten or replace

3.Tighten vise

4.Reduce hand pressure

1.Check electrical wiring to motor for continuity

2.Check power line for proper voltage

3.Replace defective parts before using cutoff saw again

4.Inspect lead terminals on motor for loose or open connections

5, Any attempt to repair this motor may create a

hazard unless repair is done by an authorized Sears Service Center.

Motor | will not start or | 1. | Short circuit in line cord | or plug | 1. | Inspect line cord or plug for damaged | |||||||

stalls; fuses or circuit |

|

|

|

|

|

|

| insulation and shorted wires | |||||

breakers blow |

| 2. | Short circuit in motor or |

| 2. | Inspect all lead terminals on motor for loose | |||||||

|

|

|

|

| loose connection |

|

|

| or worn insulation | on wires | |||

|

|

|

| 3. | Incorrect | fuses or circuit | breakers | 3. | Install correct fuses or circuit breakers | ||||

|

|

|

|

| in power | line |

|

|

|

|

|

| |

|

|

|

| 4. | Motor overloaded |

|

| 4. | Reduce load on motor | ||||

|

|

|

| 5. | Low voltage |

|

| 5. | Correct the low voltage conditions | ||||

Motor fails to develop full | 1. | Power line overloaded |

| 1. | Reduce the load on the power line | ||||||||

power | (power output of | 2. | Undersized | wires or cords too long | 2. | Increase wire sizes or reduce length of cords | |||||||

motor | decreases) | with | 3. | General | overloading | of power | 3. | Request a voltage check from the | |||||

"_ecreased voltage | at |

| company's facilities |

|

|

| power company |

| |||||

imotor terminals |

|

|

|

|

|

|

|

|

|

|

| ||

'vlotorhot or overheats | 1. | Motor overloaded |

|

| 1. | Reduce load on motor | |||||||

|

|

|

| 2. | Air circulation around | motor | 2. | Unblock air vents to provide normal air | |||||

|

|

|

|

| restricted |

|

|

|

|

| circulation around | motor | |

|

|

|

| 3. | Gears need lubrication |

| 3. | Check grease |

| ||||

|

|

|

| 4. | Worn or dirty brushes |

| 4. | Replace or clean | brushes | ||||

C/heel chipping |

| 1. | Too heavy | hand pressure | 1. | Decrease | hand pressure | ||||||

|

|

|

| 2. | Narrow workpieee |

|

| 2. | Decrease | hand pressure | |||

|

|

|

| 3. | Vibrating | workpiece |

|

| 3. | Clamp work securely | |||

Excessive | wheel |

| 1. | Abrasive wheel not rated for saw speed | 1. | Use abrasive wheels rated for saw speed | |||||||

oreakage |

|

| 2, | Misaligned | abrasive | wheel | 2. | Adjust wheel washer and nut | |||||

Premature | wheel dulling | 1. | Inadequate | hand pressure | 1. | Increase | hand pressure | ||||||

|

|

|

| 2. | Hard spots | or scale in/on material | 2. | Increase | hand pressure | ||||

|

|

|

| 3. | Work hardening of material | 3. | Increase | hand pressure | |||||

|

|

|

|

| (especially | stainless steel) |

|

|

|

| |||

6