GENERALRECOMMENDATIONSSNOW THROWER

The warranty on this snow thrower does not cover items that have been subjected to op- erator abuse or negligence. To receive full value from the warranty, the operator must maintain the snow thrower as instructed in this manual. The maintenance chart is pro- vided to assist the operator in properly maintaining the snow thrower.

Some adjustments will need to be made pe- riodically to properly maintain your snow thrower.

AFTER FIRST USE

•Check for any loose or damaged pads.

•Tighten any loose fasteners.

•Check and maintain the auger.

•After each use. remove all snow and slush off the snow thrower to prevent freezing of auger or controls.

•Check controls to make sure they are functioning properly.

•If any parts are worn or damaged, replace immediately.

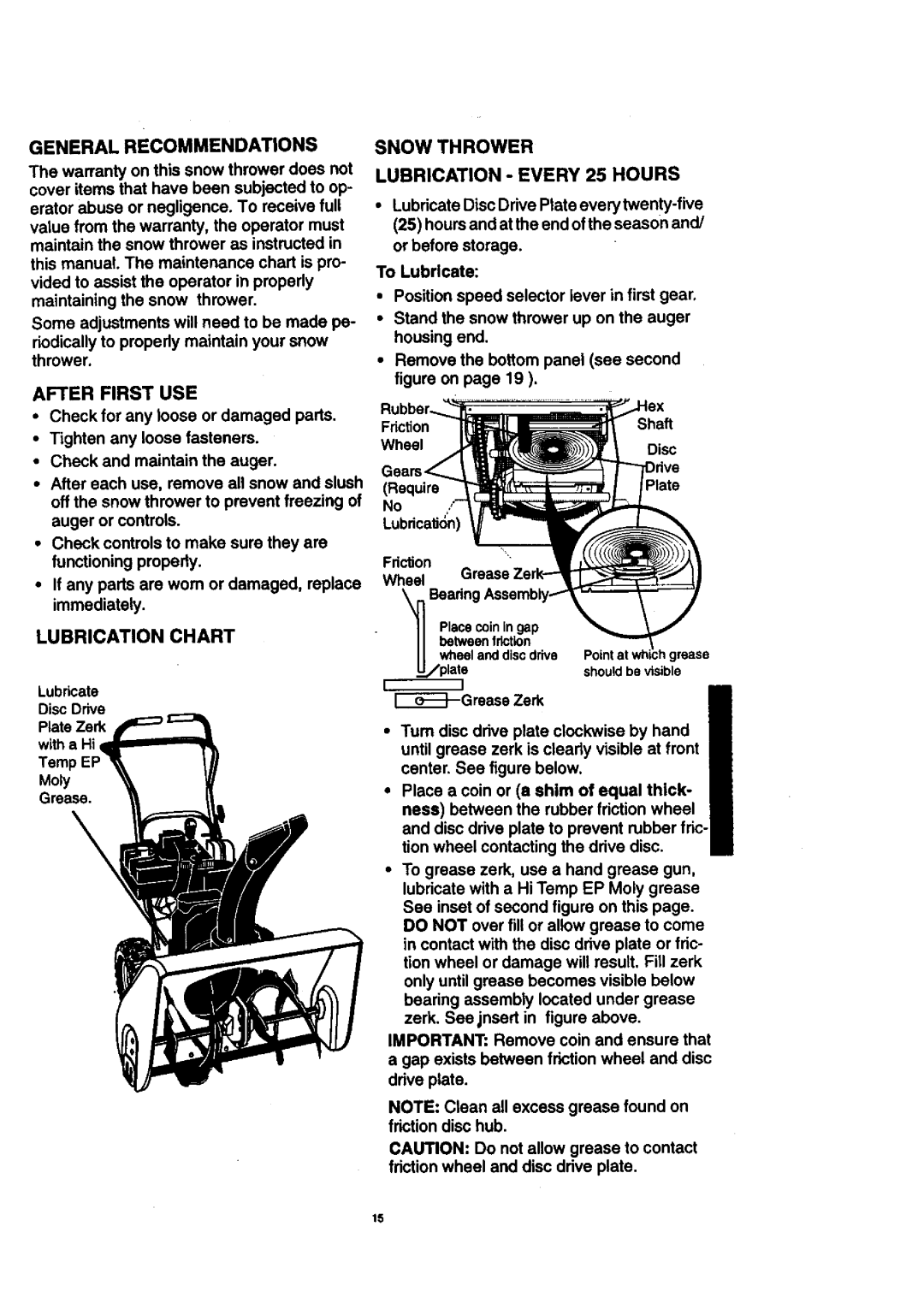

LUBRICATION CHART

Lubricate Disc Drive Plate Zerk with a Hi

Temp

Moly

Grease.

\

LUBRICATION - EVERY 25 HOURS

•Lubricate Disc Drive Plate every

(25)hours and at the end of the season and/

or before storage.

To Lubricate:

•Position speed selector isver in first gear.

•Stand the snow thrower up on the auger housing end.

•Remove the bottom panel (see second figure on page 19 ).

FrictionShaft

WheelDisc

(Require No

Fri_on

Wheel

Bearing

Placecoinin gap betweenfriction

wheelanddiscdrive1grease

plateshouldbe visible

•Tum disc drive plate clockwise by hand until grease zerk is clearly visible at front center. See figure below.

•Place a coin or (a shim of equal thick- ness) between the rubber friction wheel and disc drive plate to prevent rubber fric- tion wheel contacting the drive disc.

•To grease zerk, use a hand grease gun, lubricate with a Hi Temp EP Moly grease See inset of second figure on this page.

DO NOT over fill or allow grease to come in contact with the disc drive plate or fric- tion wheel or damage will result. Fill zerk only until grease becomes visible below bearing assembly located under grease zerk. See,insed in figure above.

IMPORTANT: Remove coin and ensure that a gap exists between friction wheel and disc drive plate.

NOTE: Clean all excess grease found on friction disc hub.

CAUTION: Do not allow grease to contact friction wheel and disc drive plate.

15