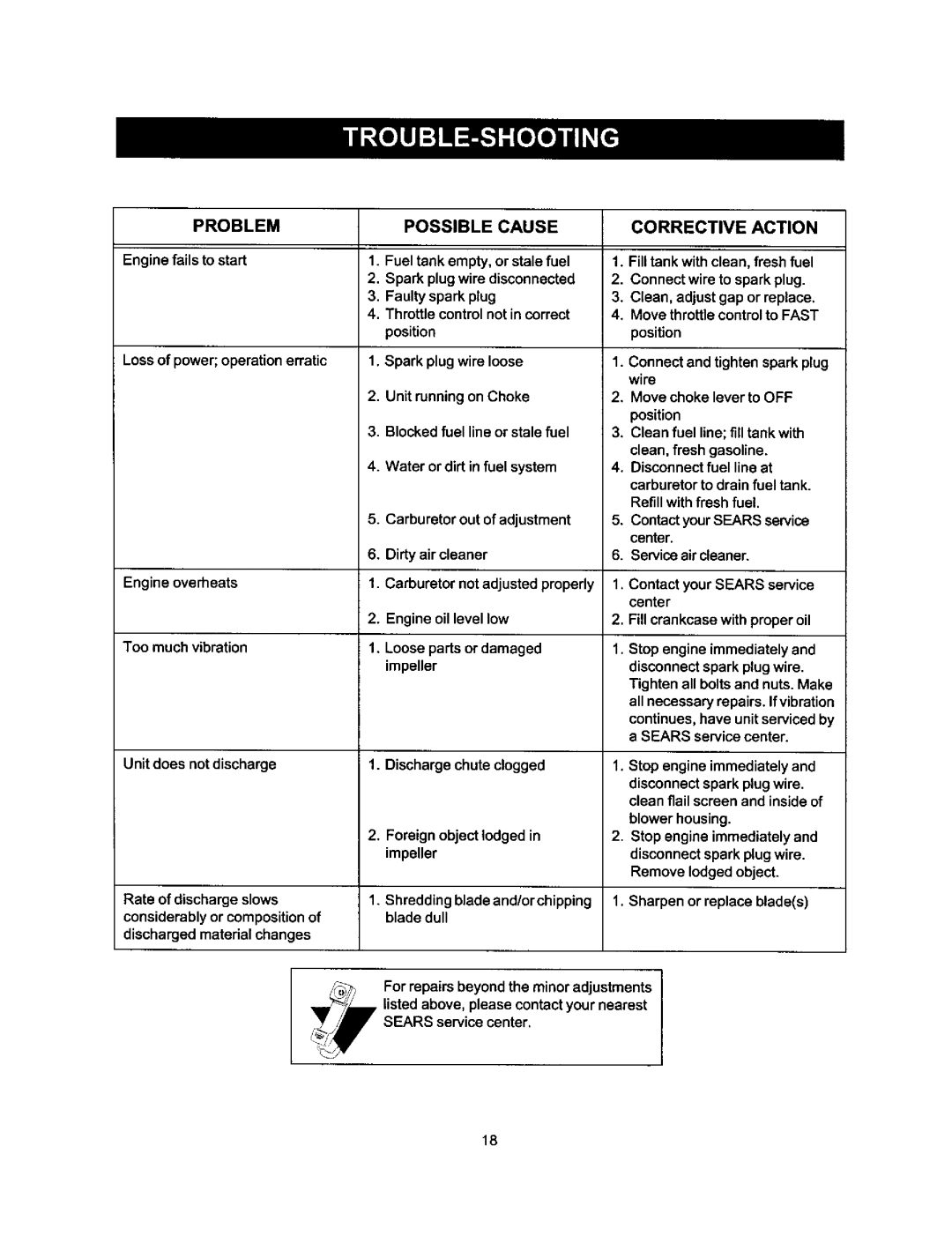

PROBLEM

POSSIBLECAUSE CORRECTIVEACTION

Enginefailstostart

Loss of power; operationerratic

Engine overheats

Too much vibration

Unit does not discharge

Rate of discharge slows considerablyor compositionof discharged material changes

1.Fueltankempty,orstalefuel

2.Spark plug wire disconnected

3.Faulty spark plug

4.Throttlecontrolnot in correct position

1.Spark plug wire loose

2.Unit runningon Choke

3.Blocked fuel line or stale fuel

4.Water or dirt in fuel system

5.Carburetor out of adjustment

6.Dirty air cleaner

1.Carburetornot adjusted properly

2.Engine oil level low

1.Loose parts or damaged impeller

1.Dischargechute clogged

2.Foreignobject lodgedin impeller

1.Shreddingblade and/orchipping blade dull

1.Fill tank with clean, fresh fuel

2.Connect wire to spark plug.

3.Clean, adjustgap or replace.

4.Move throttlecontrolto FAST position

1.Connect and tighten spark plug wire

2.Move choke lever to OFF position

3.Clean fuel line;filltank with clean, fresh gasoline.

4.Disconnect fuel lineat carburetorto drain fuel tank. Refillwith fresh fuel.

5.ContactyourSEARS service center.

6.Serviceaircleaner.

1.Contact your SEARS service center

2.Fill crankcase with properoil

1.Stop engine immediatelyand disconnectspark plug wire. Tighten all bolts and nuts.Make all necessary repairs. If vibration

continues, have unit serviced by e SEARS service center.

1.Stop engine immediatelyand

disconnectspark plug wire. clean flailscreen and inside of

blower housing.

2.Stop engine immediatelyand disconnectspark plugwire. Remove lodgedobject.

1.Sharpen or replace blade(s)

For repairs beyond the minor adjustments listed above, please contact your nearest

SEARS service center.

18