Disconnectsparkplug wire and move it away

from spark plug.

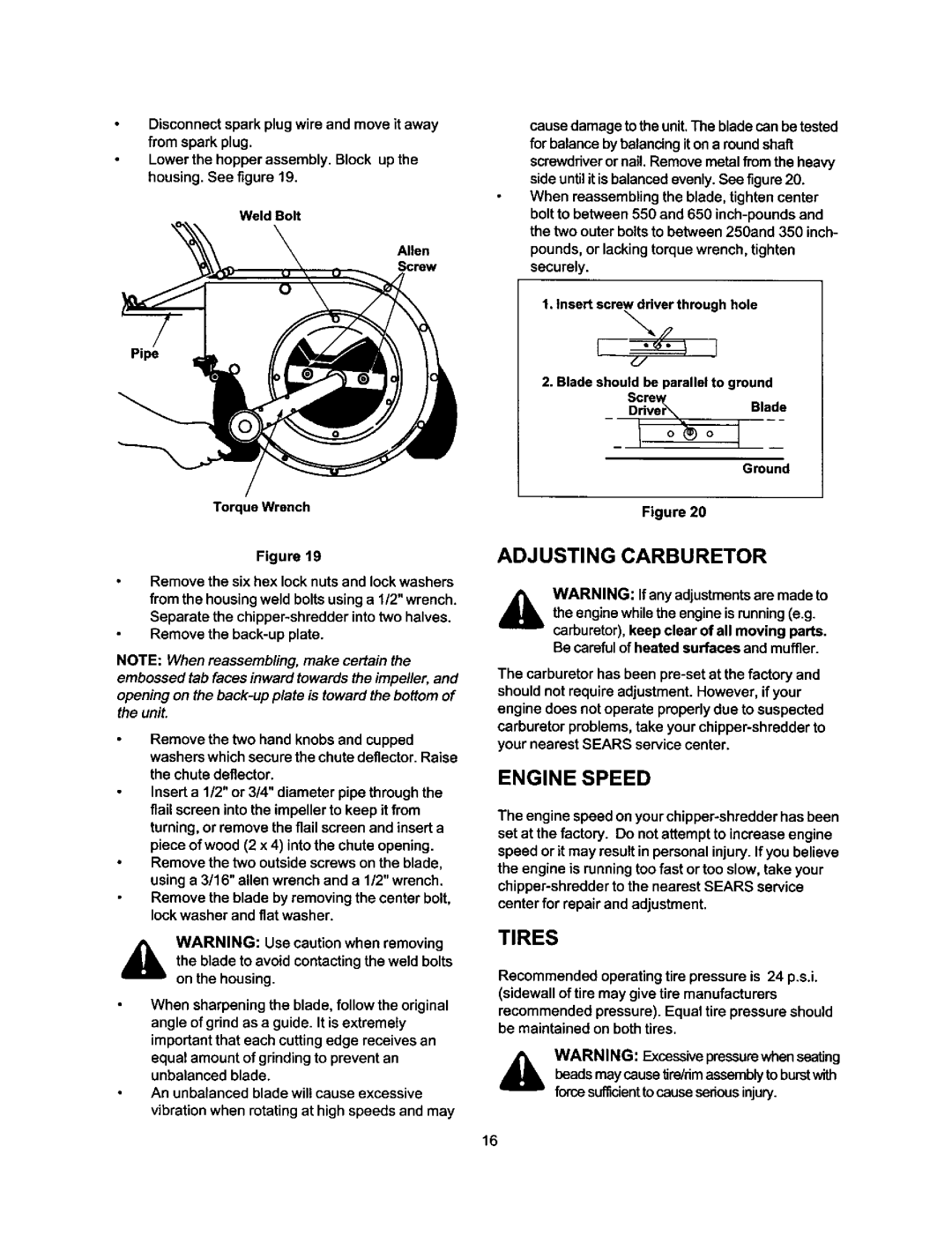

Lower the hopper assembly. Block up the housing.See figure 19.

Weld Bolt

Allen

Screw

Pipe

Torque Wrench

Figure 19

Remove the six hex lock nuts and lock washers from the housingweld boltsusing a 1/2"wrench. Separate the

Remove the back-up plate.

NOTE: When reassembling, make certain the embossed tab faces inward towards the impeller, and opening on the

Remove the two hand knobs and cupped washers whichsecure the chute deflector. Raise the chute deflector.

Inserta 1/2" or 3/4" diameter pipethrough the flail screen intothe impellerto keep itfrom turning,or remove the flail screen and insert a piece of wood (2 x 4) intothe chute opening. Remove the two outside screwson the blade, using a 3/16" allenwrench and a 1/2"wrench.

Remove the blade by removing the center bolt, lockwasher and fiat washer.

the blade to avoid contacting the weld bolts

,_ WARNING: Use caution when removing on the housing.

When sharpening the blade, follow the original angle of grind as a guide. It is extremely important that each cutting edge receives an

equat amount of grinding to prevent an unbalanced blade.

An unbalanced blade will cause excessive vibration when rotating at high speeds and may

causedamage to theunit.The bladecan be tasted for balance by balancing iton a roundshaft screwddveror nail. Removemetalfrom the heavy side untilitis balancedevenly.See figure20.

When reassemblingthe blade, tightencenter boltto between 550 and 650

pounds, or lackingtorque wrench, tighten securely.

1. insertscrewdriver throughhole

d/

2. Bladeshouldbe parallelto ground Screv_

Driver\Blade

i | I |

| Ground |

Figure 20

ADJUSTING CARBURETOR

A WARNING: If any adjustmentsare made to the engine whiletheengine isrunning(e.g.

carburetor),keep clear of all moving parts. Be careful of heated surfaces and muffler.

The carburetor has been

ENGINE SPEED

The engine speed on your

the engine is running too fast or too slow, take your

center for repair and adjustment.

TIRES

Recommendedoperating tire pressure is 24 p.s.i.

(sidewallof tire may give tire manufacturers

recommendedpressure).Equal tire pressureshould be maintained on both tires.

WARNbeadsmayING:causetire/rimassemblyExcessivepressurewhenseatingtoburstwith force sufficienttocauseserious injury.

16