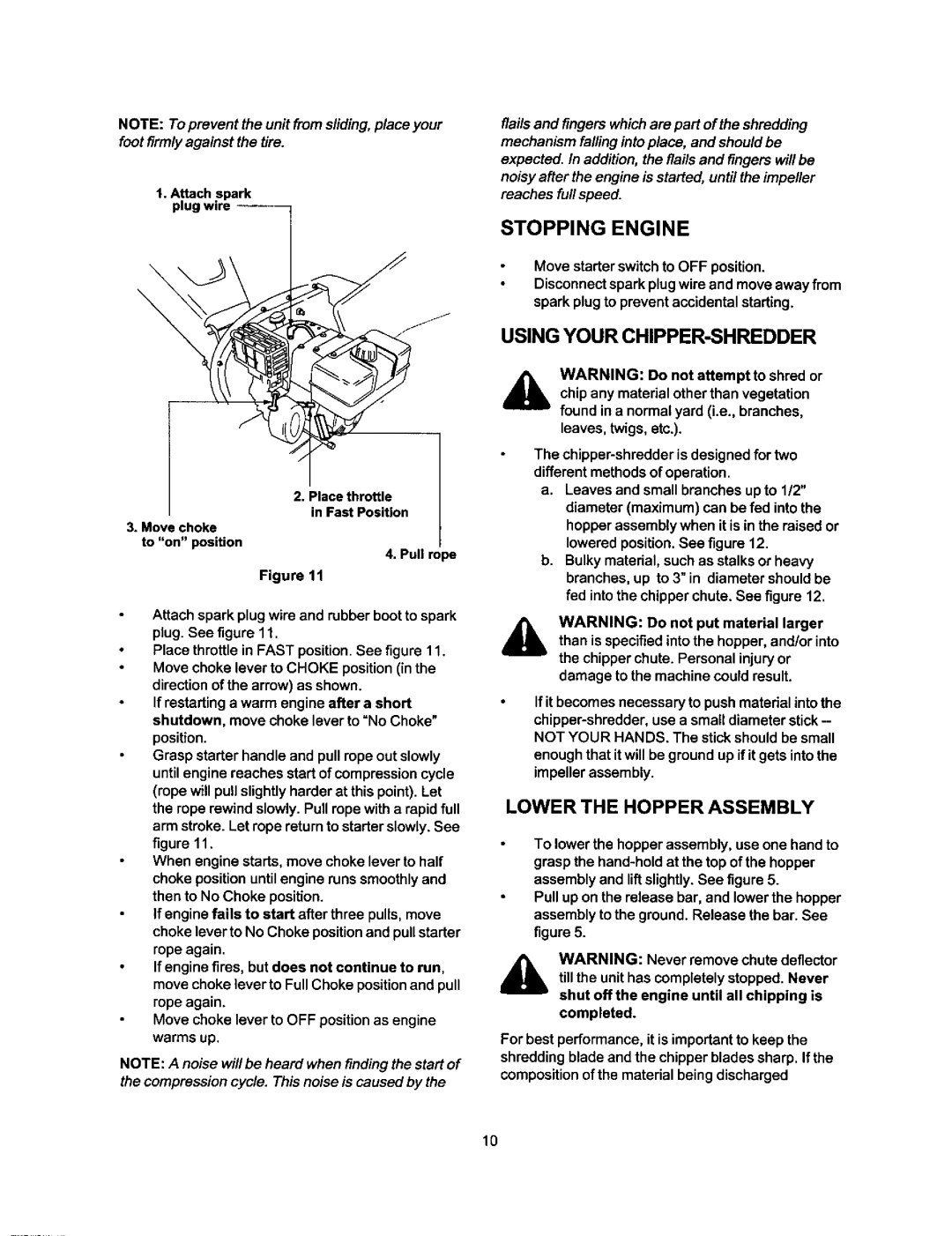

NOTE:TOprevent the unit fromsliding,place your foot firmlyagainst the tire.

1.Attach spark plug wire

\

2. Place throttle in Fast Position

3.Move choke

to "on" position

4. Pull rope

Figure 1t

Attach spark plug wire and rubber boot to spark plug. See figure 11.

Place throttle in FAST position. See figure 11. Move choke lever to CHOKE position (in the direction of the arrow) as shown.

If restarting a warm engine after a short shutdown, move choke lever to =No Choke" position.

Grasp starter handle and pull ropeout slowly untilengine reaches startof compressioncycle (rope willpull slightlyharder at this point).Let the rope rewind slowly. Pull ropewith a rapidfull arm stroke. Let rope returnto starter slowly.See figure 11.

When engine starts, move choke lever to half choke positionuntil engine runs smoothlyand then to No Choke position.

If engine fails to start after three pulls, move choke lever to No Choke positionand pullstarter rope again.

Ifengine rims, but does not continue to run, move choke lever to Full Choke positionand pull rope again.

Move choke lever to OFF positionas engine warms up.

NOTE: A noise will be heard when finding the start of

the compression cycle. This noise is caused by the

flails and fingers which are part of the shredding

mechanism falling intoplace, and shouldbe

expected./n addition,the flails and fingers will be noisyafter the engine is started, untilthe impeller

reaches furl speed.

STOPPING ENGINE

Move starter switch to OFF position.

Disconnect spark plugwire and move away from spark plug to preventaccidentalstarting.

USING YOUR CHIPPER-SHREDDER

A WARNING: Do not attempt to shred or chip any matedal otherthan vegetation found in a normal yard (i.e., branches, leaves, twigs,etc.).

The

a.Leaves and small branches up to 1/2" diameter (maximum) can be fed intothe hopperassembly when it is in the raisedor lowered position.See figure 12.

b.Bulky material,such as stalksor heavy branches,up to 3" in diameter shouldbe fed intothe chipperchute. See figure 12.

A WARNING: Do not put material larger than is specifiedinto the hopper, and/or into

the chipperchute. Personal injuryor damage to the machinecould result.

If it becomes necessaryto pushmaterialintothe

enoughthat itwill be ground up if it gets intothe impellerassembly.

LOWER THE HOPPER ASSEMBLY

To lowerthe hopper assembly, use one handto

grasp the

assembly and lift slightly.See figure 5.

Pullup on the release bar, and lower the hopper assembly to the ground.Release the bar. See

figure 5.

A WARNING: Never remove chute deflector tillthe unit has completely stopped.Never

shut offthe engine until all chipping is completed.

For best performance, it is important to keep the shreddingblade and the chipper blades sharp. If the composition of the material being discharged

10