8.Use gauge on oil fill cap/dipstick for checking level. For accurate reading, tighten dipstick cap securely onto the tube before removing dipstick. Keep oil at "FULL' line on dipstick. Tighten cap onto the tube securely when finished.

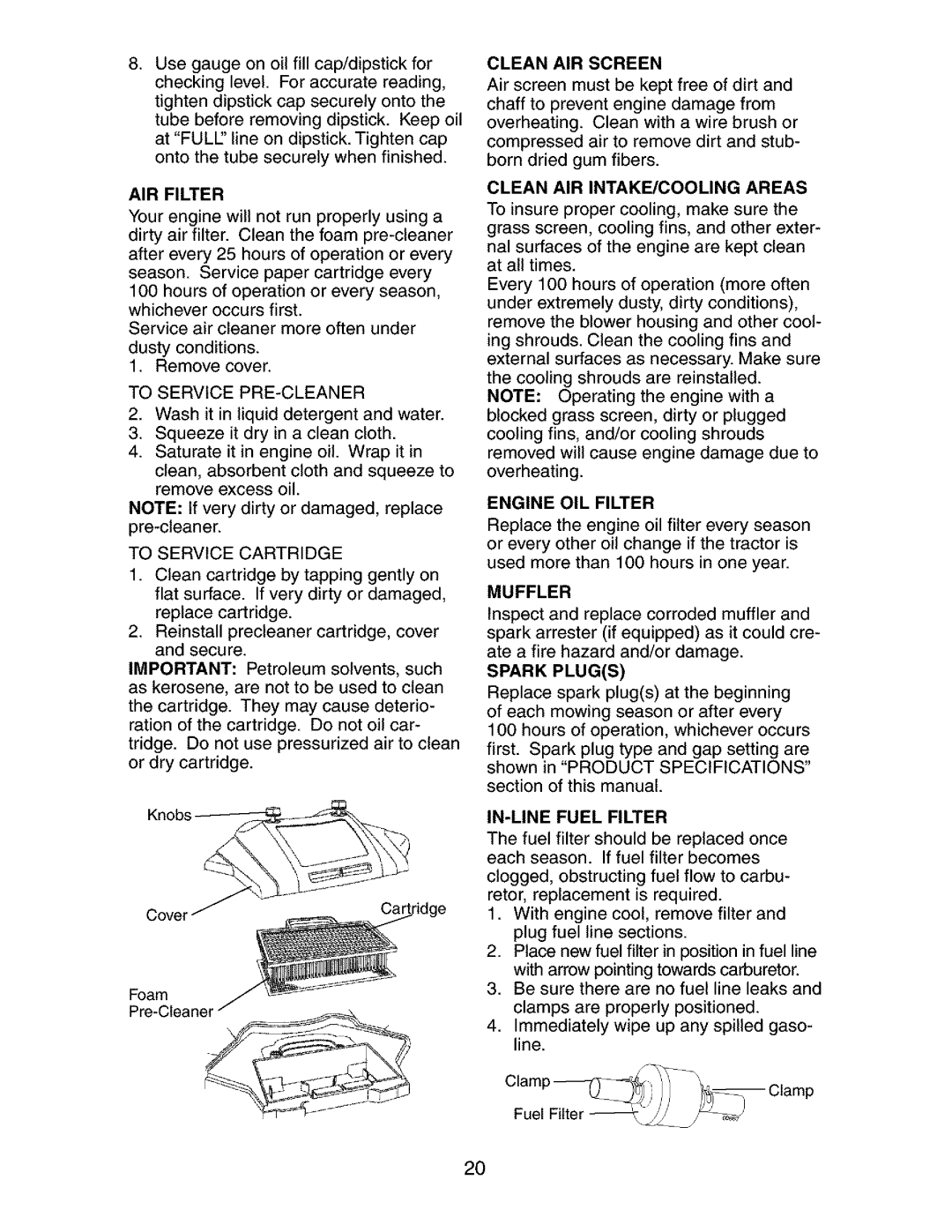

AIR FILTER

Your engine will not run properly using a dirty air filter. Clean the foam

after every 25 hours of operation or every season. Service paper cartridge every 100 hours of operation or every season, whichever occurs first.

Service air cleaner more often under

dusty conditions.

1. Remove cover.

TO SERVICE PRE-CLEANER

2.Wash it in liquid detergent and water.

3.Squeeze it dry in a clean cloth.

4.Saturate it in engine oil. Wrap it in

clean, absorbent cloth and squeeze to remove excess oil.

NOTE: If very dirty or damaged, replace

TO SERVICE CARTRIDGE

1.Clean cartridge by tapping gently on flat surface. If very dirty or damaged, replace cartridge.

2.Reinstall precleaner cartridge, cover and secure.

IMPORTANT: Petroleum solvents, such as kerosene, are not to be used to clean

the cartridge. They may cause deterio- ration of the cartridge. Do not oil car- tridge. Do not use pressurized air to clean or dry cartridge.

Cover

Foam

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff to prevent engine damage from overheating. Clean with a wire brush or compressed air to remove dirt and stub- born dried gum fibers.

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the grass screen, cooling fins, and other exter-

nal surfaces of the engine are kept clean at all times.

Every 100 hours of operation (more often under extremely dusty, dirty conditions), remove the blower housing and other cool- ing shrouds. Clean the cooling fins and external surfaces as necessary. Make sure the cooling shrouds are reinstalled.

NOTE: Operating the engine with a blocked grass screen, dirty or plugged cooling fins, and/or cooling shrouds removed will cause engine damage due to overheating.

ENGINE OIL FILTER

Replace the engine oil filter every season or every other oil change if the tractor is used more than 100 hours in one year.

MUFFLER

Inspect and replace corroded muffler and spark arrester (if equipped) as it could cre- ate a fire hazard and/or damage.

SPARK PLUG(S)

Replace spark plug(s) at the beginning of each mowing season or after every 100 hours of operation, whichever occurs

first. Spark plug type and gap setting are shown in "PRODUCT SPECIFICATIONS"

section of this manual.

IN-LINE FUEL FILTER

The fuel filter should be replaced once each season. If fuel filter becomes

clogged, obstructing fuel flow to carbu- retor, replacement is required.

1.With engine cool, remove filter and plug fuel line sections.

2.Place new fuel filter in position in fuel line with arrow pointing towards carburetor.

3.Be sure there are no fuel line leaks and clamps are properly positioned.

4.Immediately wipe up any spilled gaso- line.

Clam

20