TRACTOR

Always observe safety rutes when per- forming any maintenance.

BRAKE OPERATmON

If tractor requires more than six (6) feet stopping distance at high speed in highest

gear, then brake must be adjusted. (See "TO ADJUST BRAKE" in the Service and

Adjustments section of this manual). TmRES

,Maintain proper air pressure in all tires (See "PRODUCT SPECIFICATIONS" section of this manual).

*Keep tires free of gasoline, oil, or insect control chemicals which can harm rub- ber.

*Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent flat tires due to slow leaks, tire sealant may be purchased from your local parts

dealer. Tire sealant also prevents tire dry rot and corrosion.

OPERATOR PRESENCE SYSTEM

Be sure operator presence and interlock systems are working properly. If your trac- tor does not function as described, repair the problem immediately.

The engine should not start unless the

clutch/brake pedal is fully depressed

and attachement clutch control is in the disengaged position.

When the engine is running, any at- tempt by the operator to leave the seat without first setting the parking brake should shut off the engine.

When the engine is running and the attachment clutch is engaged, any at- tempt by the operator to leave the seat should shut off the engine.

The attachment clutch should never op- erate unless the operator is in the seat.

BLADE CARE

For best results mower blades must be kept sharp. Replace bent or damaged blades.

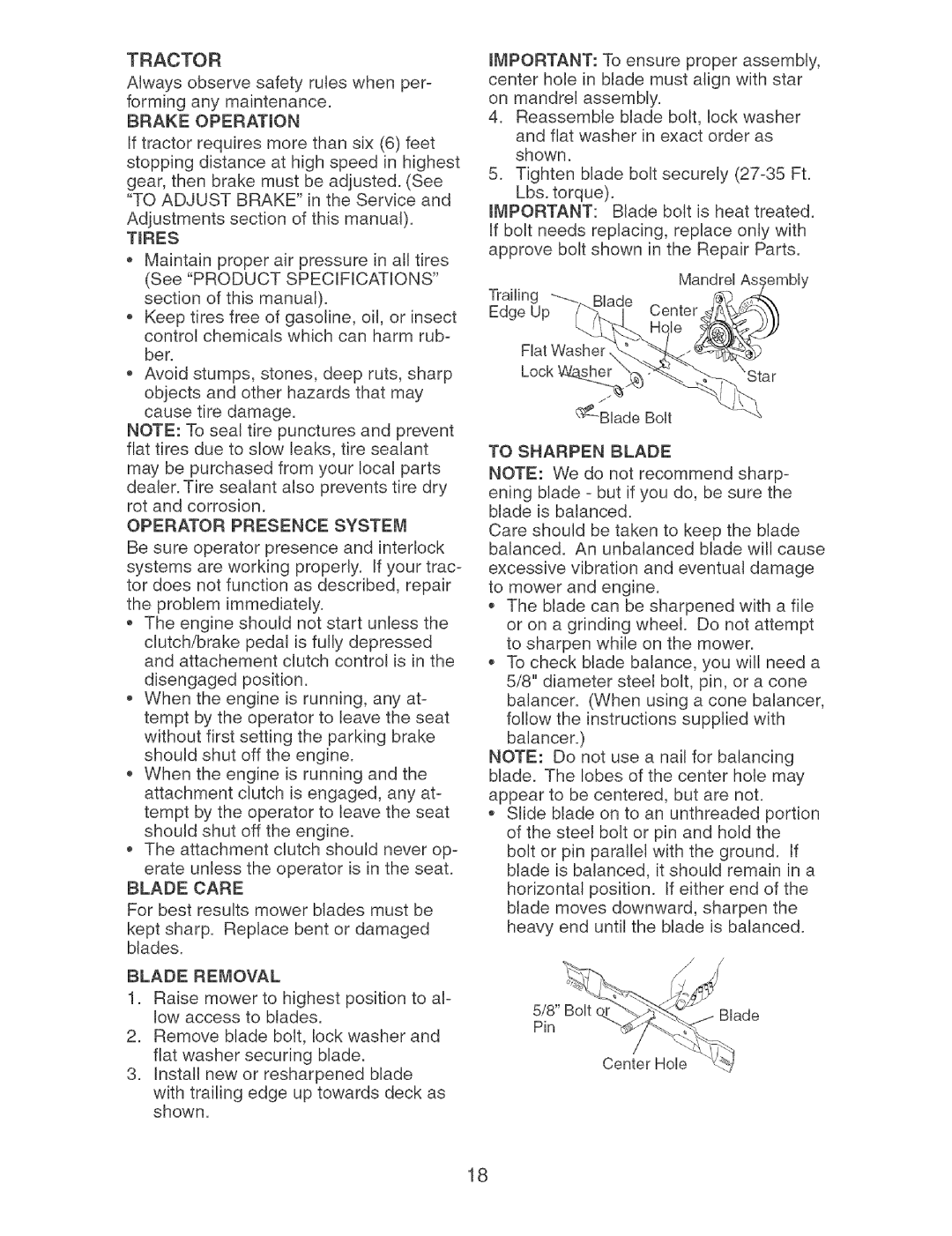

BLADE REMOVAL

1.Raise mower to highest position to al- low access to blades.

2.Remove blade bolt, lock washer and flat washer securing blade.

3.Install new or resharpened blade

with trailing edge up towards deck as shown.

mMPORTANT: To ensure proper assembly, center hole in blade must align with star on mandrel assembly.

4.Reassemble blade bolt, lock washer and flat washer in exact order as shown.

5.Tighten blade bolt securely

Lbs. torque).

mMPORTANT: Blade bolt is heat treated. If bolt needs replacing, replace only with approve bolt shown in the Repair Parts.

| Mandrel As._ |

Trailing |

|

Edge Up | Center |

Lock |

|

TO SHARPEN BLADE

NOTE: We do not recommend sharp- ening blade - but if you do, be sure the blade is balanced.

Care should be taken to keep the blade balanced. An unbalanced blade will cause

excessive vibration and eventual damage to mower and engine.

The blade can be sharpened with a file or on a grinding wheel. Do not attempt to sharpen while on the mower.

To check blade balance, you will need a 5/8" diameter steel bolt, pin, or a cone balancer. (When using a cone balancer, follow the instructions supplied with balancer.)

NOTE: Do not use a nail for balancing blade. The lobes of the center hole may appear to be centered, but are not.

Slide blade on to an unthreaded portion of the steel bolt or pin and hold the bolt or pin parallel with the ground. If blade is balanced, it should remain in a horizontal position. If either end of the blade moves downward, sharpen the heavy end until the blade is balanced.

5/8" Bolt ( | Blade |

Pin |

|

Center | Hole |

18