Your new tiller has been assembled at the factory with the exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR

ASSEMBLY

A socket wrench set will make assembly easier. Standard wrench sizes are listed.

(1)Utility knife

(2)1/2 Wrench

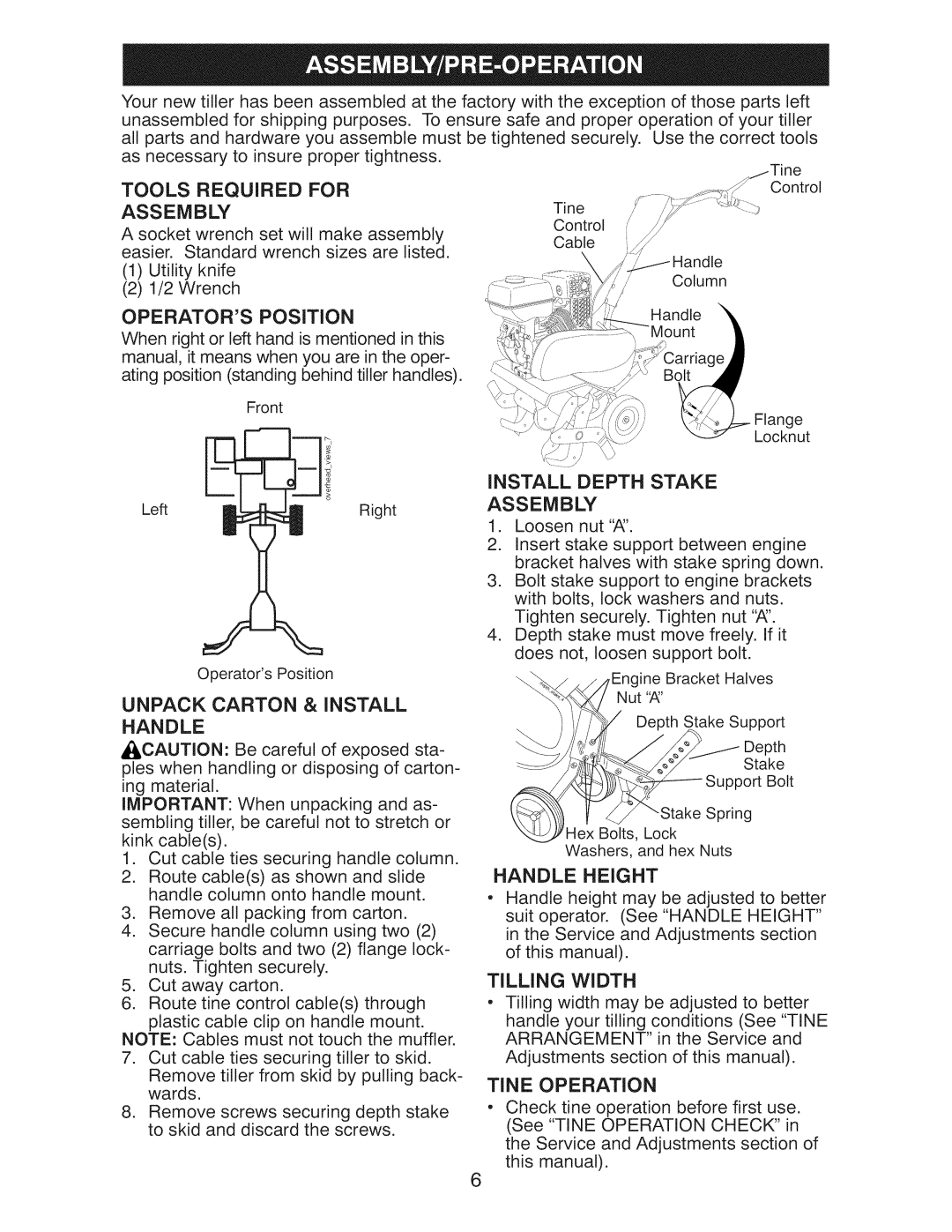

OPERATOR'S POSITION

When right or left hand is mentioned in this manual, it means when you are in the oper- ating position (standing behind tiller handles).

Front

LeftRight

Operator's Position

UNPACK CARTON & INSTALL HANDLE

_CAUTION: Be careful of exposed sta- ples when handling or disposing of carton- ing material.

IMPORTANT: When unpacking and as- sembling tiller, be careful not to stretch or kink cable(s).

1.Cut cable ties securing handle column.

2.Route cable(s) as shown and slide handle column onto handle mount.

3.Remove all packing from carton.

4.Secure handle column using two (2) carriage bolts and two (2) flange lock- nuts. Tighten securely.

5.Cut away carton.

6.Route tine control cable(s) through

plastic cable clip on handle mount. NOTE: Cables must not touch the muffler.

7.Cut cable ties securing tiller to skid.

Remove tiller from skid by pulling back- wards.

8.Remove screws securing depth stake to skid and discard the screws.

Tine

Control

Cable

Column

Handle "_

)unt I

Flange

Locknut

INSTALL DEPTH STAKE

ASSEMBLY

1.Loosen nut'S'.

2.Insert stake support between engine bracket halves with stake spring down.

3.Bolt stake support to engine brackets with bolts, lock washers and nuts.

Tighten securely. Tighten nut '7_'.

4.Depth stake must move freely. If it does not, loosen support bolt.

Engine Bracket Halves

Nut '_'

Depth Stake Support

Depth

Stake pport Bolt

Spring

Hex Bolts, Lock

Washers, and hex Nuts

HANDLE HEIGHT

•Handle height may be adjusted to better suit operator. (See "HANDLE HEIGHT"

in the Service and Adjustments section of this manual),

TILLING WIDTH

• Tilling width may be adjusted to better handle your tilling conditions (See "TINE ARRANGEMENT" in the Service and

Adjustments section of this manual).

TINE OPERATION

•Check tine operation before first use. (See "TINE OPERATION CHECK" in the Service and Adjustments section of this manual).

6