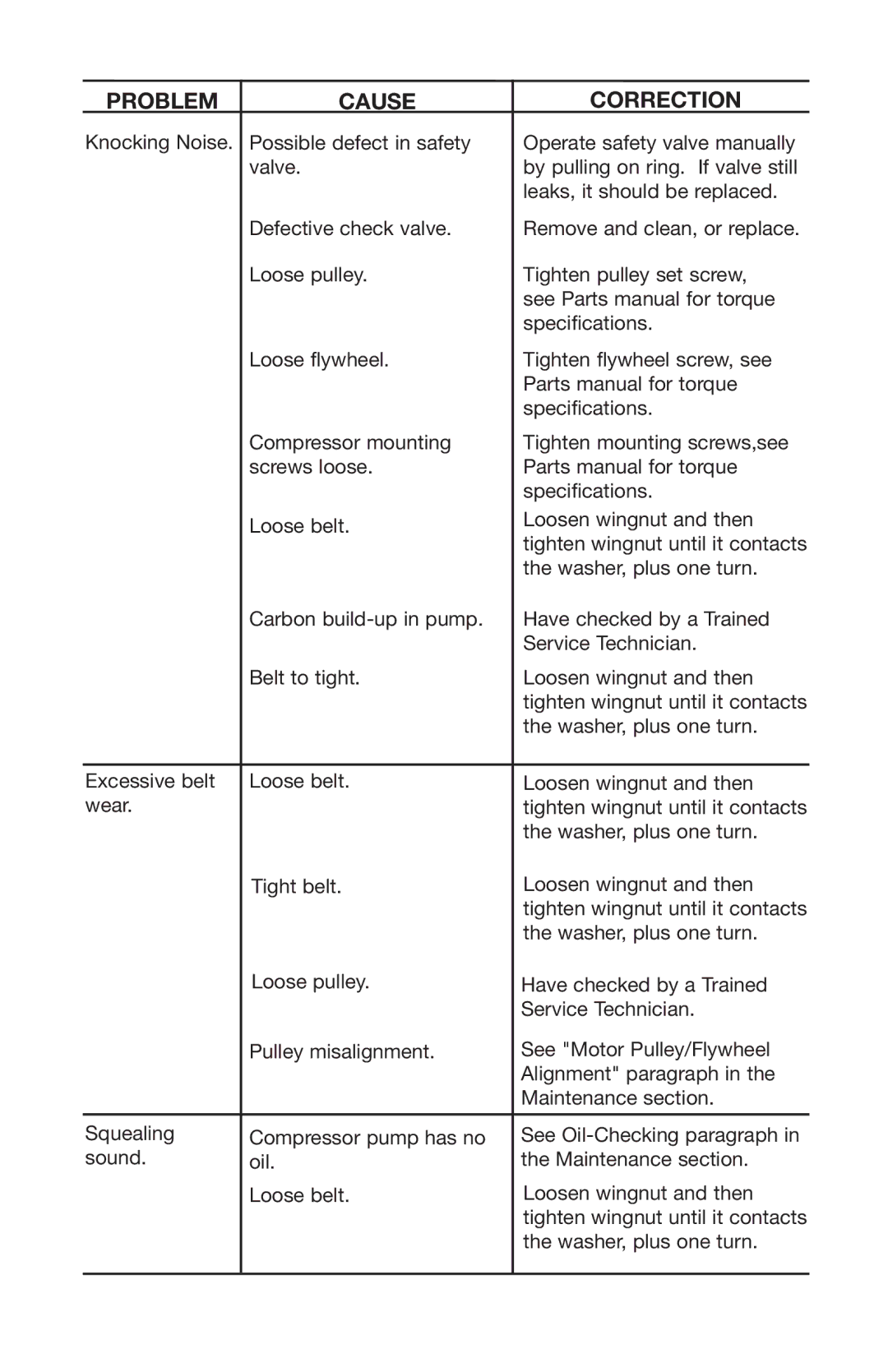

PROBLEM |

| CAUSE | CORRECTION | |

Knocking Noise. |

| Possible defect in safety | Operate safety valve manually | |

|

| valve. | by pulling on ring. If valve still | |

|

|

|

| leaks, it should be replaced. |

|

| Defective check valve. | Remove and clean, or replace. | |

|

| Loose pulley. | Tighten pulley set screw, | |

|

|

|

| see Parts manual for torque |

|

|

|

| specifications. |

|

| Loose flywheel. | Tighten flywheel screw, see | |

|

|

|

| Parts manual for torque |

|

|

|

| specifications. |

|

| Compressor mounting | Tighten mounting screws,see | |

|

| screws loose. | Parts manual for torque | |

|

|

|

| specifications. |

|

| Loose belt. | Loosen wingnut and then | |

|

| tighten wingnut until it contacts | ||

|

|

|

| |

|

|

|

| the washer, plus one turn. |

|

| Carbon | Have checked by a Trained | |

|

|

|

| Service Technician. |

|

| Belt to tight. | Loosen wingnut and then | |

|

|

|

| tighten wingnut until it contacts |

|

|

|

| the washer, plus one turn. |

|

|

|

|

|

Excessive belt |

| Loose belt. | Loosen wingnut and then | |

wear. |

|

|

| tighten wingnut until it contacts |

|

|

|

| the washer, plus one turn. |

|

| Tight belt. | Loosen wingnut and then | |

|

|

|

| tighten wingnut until it contacts |

|

|

|

| the washer, plus one turn. |

|

| Loose pulley. | Have checked by a Trained | |

|

|

|

| Service Technician. |

|

| Pulley misalignment. | See "Motor Pulley/Flywheel | |

|

|

|

| Alignment" paragraph in the |

|

|

|

| Maintenance section. |

|

|

|

|

|

Squealing |

|

|

| See |

| Compressor pump has no | |||

sound. |

| oil. |

| the Maintenance section. |

|

|

|

| Loosen wingnut and then |

|

| Loose belt. |

| |

|

|

|

| tighten wingnut until it contacts |

|

|

|

| the washer, plus one turn. |

|

|

|

| |

|

|

|

|

|