6.Remove the filter by turning it counterclockwise using an automotive type filter wrench to loosen.

7.Allow the old oil to completely drain from the engine crankcase into the container below. To close the drain valve, push it inward, turn clockwise until it stops and then release it.

8.Remove the flexible tubing from the drain valve. Clean the tubing and store in a safe place for future use.

9.Clean the drain valve and push the plastic dust cap onto the valve.

10.To assure a continuous flow of oil to all critical lubrication points within the engine, pour some new oil into the threaded center hole of the filter and allow time for the oil to be absorbed into the filter material.

11.Apply a light coating of clean oil on the gasket of the new oil filter. Thread the filter on by hand until the gasket contacts the oil filter adapter, then tighten the filter an additional 1/2 to 3/4 turn.

Refer to FILLING THE CRANKCASE and to the LUBRICATION TABLE and refill the crankcase with the quantity and type of oil specified.

FILLING THE CRANKCASE

![]() CAUTION

CAUTION

Never overfill the engine crankcase. The engine may overheat and/or damage may result if the crankcase is below the “LOW” mark or over the “FULL” mark on the dipstick. For best results, fill to the “FULL” mark on the dipstick as opposed to adding a given quantity of oil. Always check the level on the dipstick before adding more oil.

Refer to the LUBRICATION TABLE for information regarding the oil capacity and the proper type of oil to pour into the crankcase.

1.Place the tractor on a level surface and engage the brake pedal lock. Stop the tractor engine and remove the ignition key.

2.Clean the area around the oil fill tube and oil fill cap/dipstick to prevent debris from entering the crankcase.

3.Remove the oil fill cap/dipstick from the oil fill tube and SLOWLY pour oil into the fill tube. The oil capacity is approximately 4 pints. Fill the crankcase until the oil level reaches the “FULL” mark on the dipstick (Refer to Figure 19).

4.Reinstall the oil fill cap/dipstick securely into the oil fill tube

![]() CAUTION

CAUTION

The oil fill capdipstick MUST BE INSTALLED SECURELY INTO THE TUBE AT ALL TIMES WHEN THE ENGINE IS OPERATING. Severe engine damage could result from failure to do so.

5.Start the tractor engine and allow it to run for 30 seconds, then stop the engine and remove the ignition key.

6.Check the oil level and add oil if necessary. DO NOT OVERFILL THE ENGINE CRANKCASE.

7.Check the oil filter and drain plug for leaks.

CHECKING TRANSMISSION OIL LEVEL

![]() NOTE

NOTE

Check the oil level only while the engine is stopped and the tractor is level.

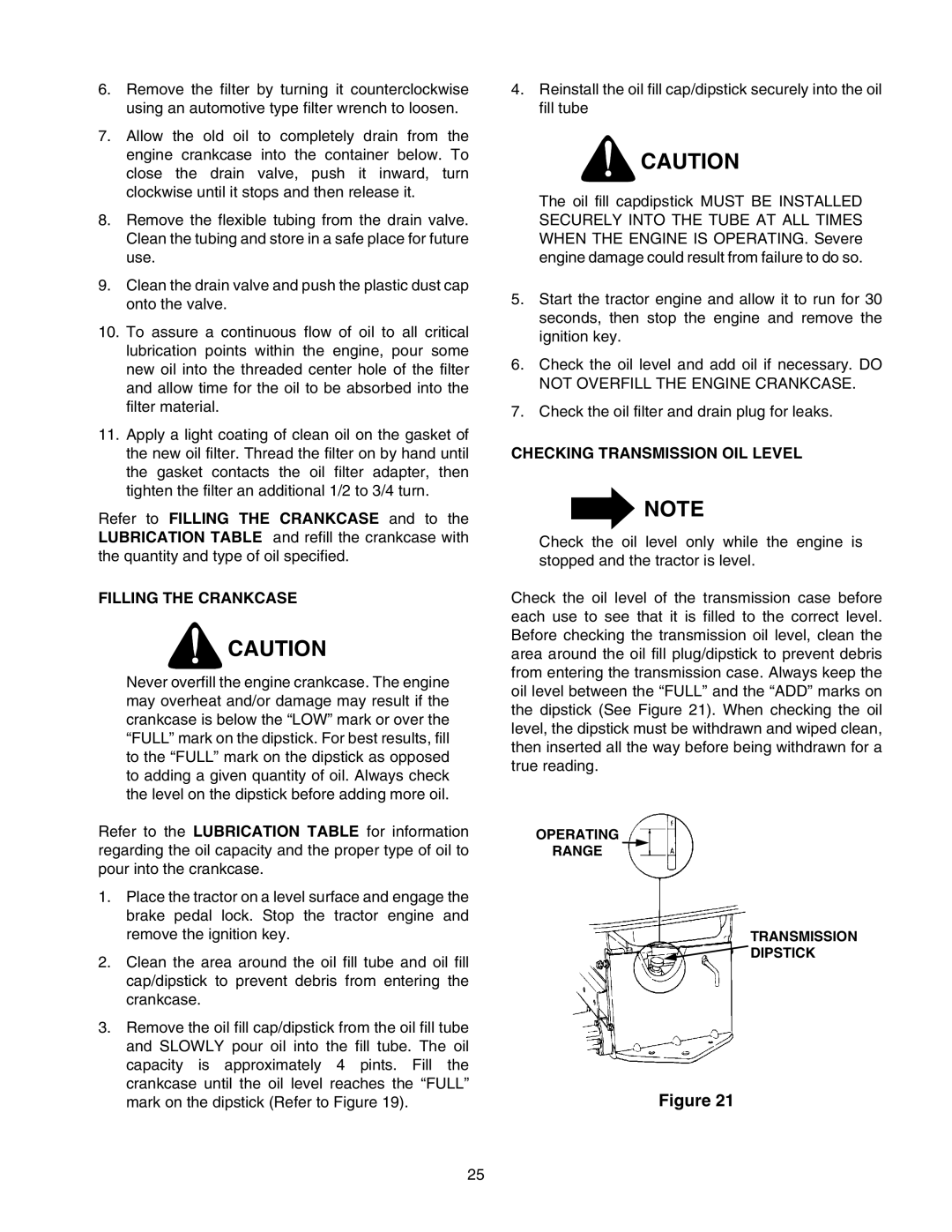

Check the oil level of the transmission case before each use to see that it is filled to the correct level. Before checking the transmission oil level, clean the area around the oil fill plug/dipstick to prevent debris from entering the transmission case. Always keep the oil level between the “FULL” and the “ADD” marks on the dipstick (See Figure 21). When checking the oil level, the dipstick must be withdrawn and wiped clean, then inserted all the way before being withdrawn for a true reading.

OPERATING

RANGE

TRANSMISSION

![]() DIPSTICK

DIPSTICK

Figure 21

25