•Place a suitable container beneath the front of the axle housing.

•Remove the oil fill plug/dipstick to help vent the axle, then remove the drain plug and allow the oil to drain into the container. Reinstall the drain plug after draining the oil. See Figure 46.

•Fill the axle with Cub Cadet Gear Lube until the oil level reaches the full mark on the dipstick. Do not over fill the axle housing.

•Reinstall the fill plug/dipstick in the axle housing.

•Move the drain pan underneath either of the final reduction gear cases.

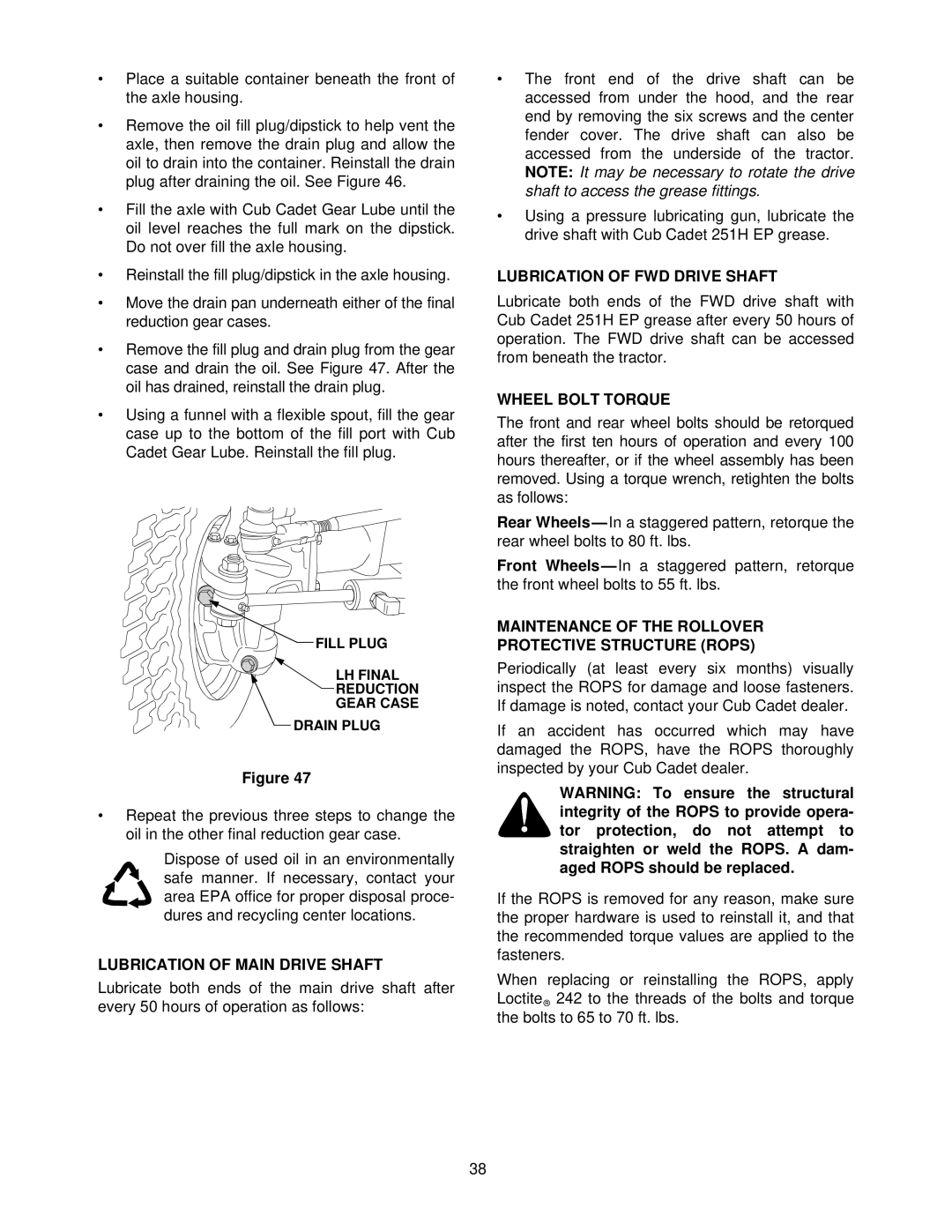

•Remove the fill plug and drain plug from the gear case and drain the oil. See Figure 47. After the oil has drained, reinstall the drain plug.

•Using a funnel with a flexible spout, fill the gear case up to the bottom of the fill port with Cub Cadet Gear Lube. Reinstall the fill plug.

![]() FILL PLUG

FILL PLUG

LH FINAL

REDUCTION

GEAR CASE

DRAIN PLUG

Figure 47

•Repeat the previous three steps to change the oil in the other final reduction gear case.

Dispose of used oil in an environmentally safe manner. If necessary, contact your area EPA office for proper disposal proce- dures and recycling center locations.

LUBRICATION OF MAIN DRIVE SHAFT

Lubricate both ends of the main drive shaft after every 50 hours of operation as follows:

•The front end of the drive shaft can be accessed from under the hood, and the rear end by removing the six screws and the center fender cover. The drive shaft can also be accessed from the underside of the tractor. NOTE: It may be necessary to rotate the drive shaft to access the grease fittings.

•Using a pressure lubricating gun, lubricate the drive shaft with Cub Cadet 251H EP grease.

LUBRICATION OF FWD DRIVE SHAFT

Lubricate both ends of the FWD drive shaft with Cub Cadet 251H EP grease after every 50 hours of operation. The FWD drive shaft can be accessed from beneath the tractor.

WHEEL BOLT TORQUE

The front and rear wheel bolts should be retorqued after the first ten hours of operation and every 100 hours thereafter, or if the wheel assembly has been removed. Using a torque wrench, retighten the bolts as follows:

Rear

Front

MAINTENANCE OF THE ROLLOVER

PROTECTIVE STRUCTURE (ROPS)

Periodically (at least every six months) visually inspect the ROPS for damage and loose fasteners. If damage is noted, contact your Cub Cadet dealer.

If an accident has occurred which may have damaged the ROPS, have the ROPS thoroughly inspected by your Cub Cadet dealer.

WARNING: To ensure the structural integrity of the ROPS to provide opera- tor protection, do not attempt to straighten or weld the ROPS. A dam- aged ROPS should be replaced.

If the ROPS is removed for any reason, make sure the proper hardware is used to reinstall it, and that the recommended torque values are applied to the fasteners.

When replacing or reinstalling the ROPS, apply Loctite® 242 to the threads of the bolts and torque the bolts to 65 to 70 ft. lbs.

38