Adjust Flywheel/Chain Tension

Over time and after substantial use, the chain on the CycleOps Pro Series indoor cycle will stretch. Adjusting the tension/align- ment is a difficult task and improper adjustment can lead to premature chain/cog wear. It is recommended this task be done with assistance from an authorized indoor cycle dealer. The chain tension has been adjusted properly when there is little or no play felt when the pedals are rocked back and forth.

NOTE: Be sure to make small incremental adjustments to the tensioning hardware on both sides of the flywheel. Only adjusting one side will lead to improper flywheel alignment and unwanted drive train wear and/or noise.

CAUTION: Improper chain adjustment will cause premature wear and may void the warranty.

CAUTION: NEVER put hands into or near the drive train while it is motion!

Vertical

Travel

Flange

Nut

Axle Lock

Nut

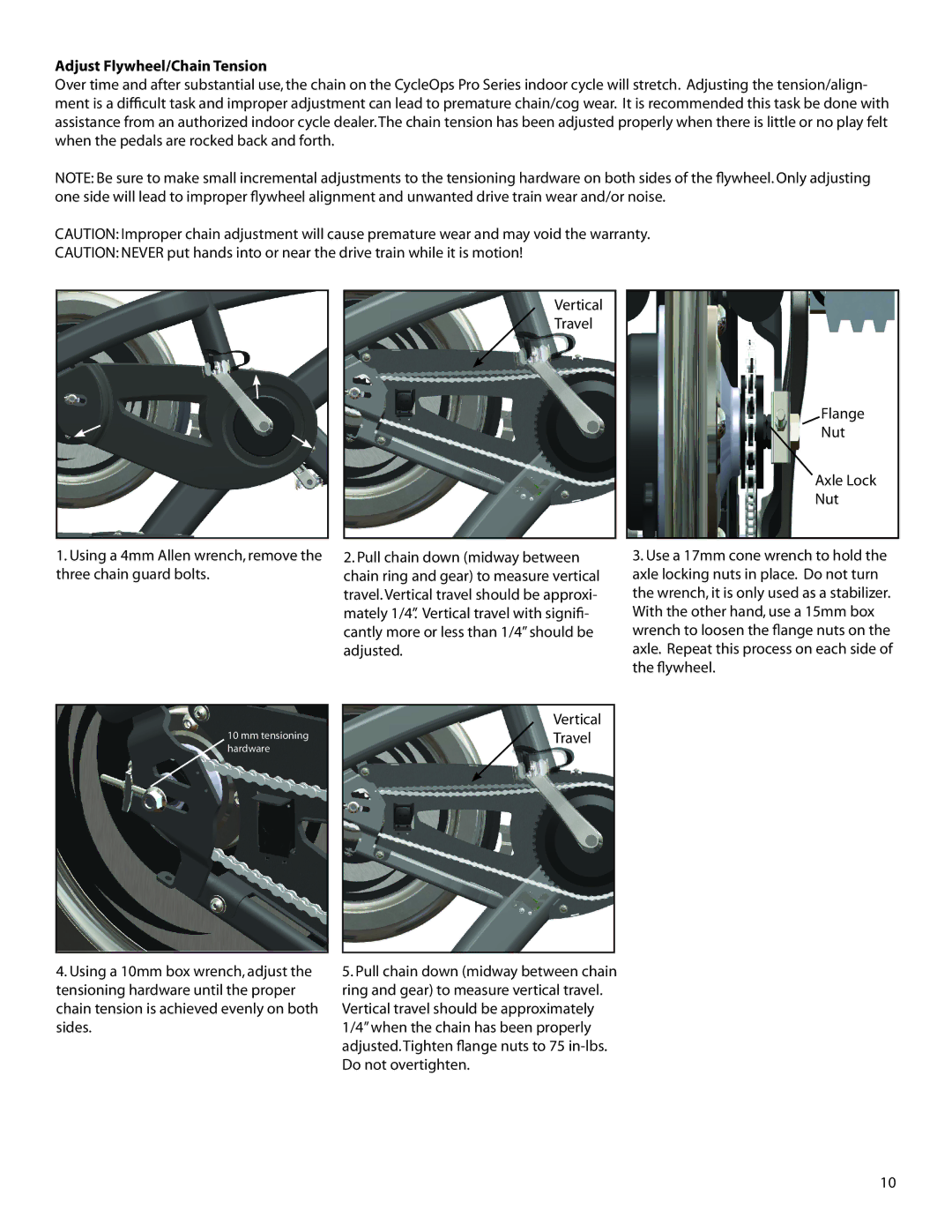

1.Using a 4mm Allen wrench, remove the three chain guard bolts.

2.Pull chain down (midway between chain ring and gear) to measure vertical travel. Vertical travel should be approxi- mately 1/4”. Vertical travel with signifi- cantly more or less than 1/4” should be adjusted.

3. Use a 17mm cone wrench to hold the axle locking nuts in place. Do not turn the wrench, it is only used as a stabilizer. With the other hand, use a 15mm box wrench to loosen the flange nuts on the axle. Repeat this process on each side of the flywheel.

10 mm tensioning hardware

Vertical Travel

4.Using a 10mm box wrench, adjust the tensioning hardware until the proper chain tension is achieved evenly on both sides.

5.Pull chain down (midway between chain ring and gear) to measure vertical travel. Vertical travel should be approximately 1/4” when the chain has been properly adjusted. Tighten flange nuts to 75

10