Dayton Operating Instructions and Parts Manual | 3WY47, 3W735B, 3W736C, 3WY44, 3TE27A, 3WY45, and 3WY46 |

Dayton® Professional-Duty

Electric Generators

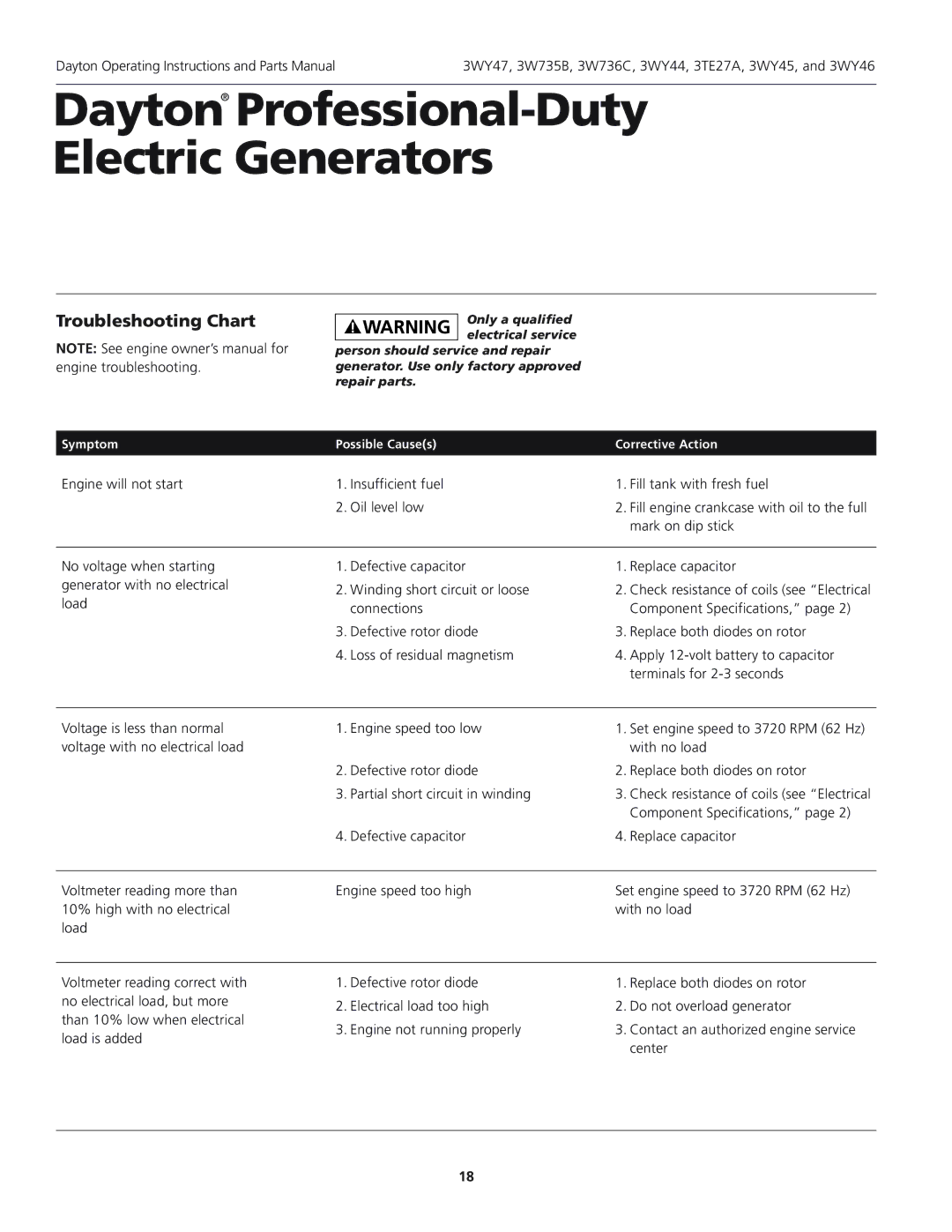

Troubleshooting Chart

NOTE: See engine ownerÕs manual for engine troubleshooting.

Symptom

Only a qualified electrical service

person should service and repair generator. Use only factory approved repair parts.

Possible Cause(s) | Corrective Action |

Engine will not start | 1. Insufficient fuel | 1. Fill tank with fresh fuel |

| 2. Oil level low | 2. Fill engine crankcase with oil to the full |

|

| mark on dip stick |

No voltage when starting generator with no electrical load

1. Defective capacitor | 1. Replace capacitor |

2. Winding short circuit or loose | 2. Check resistance of coils (see ÒElectrical |

connections | Component Specifications,Ó page 2) |

3. Defective rotor diode | 3. Replace both diodes on rotor |

4. Loss of residual magnetism | 4. Apply |

| terminals for |

Voltage is less than normal | 1. Engine speed too low | 1. Set engine speed to 3720 RPM (62 Hz) |

voltage with no electrical load |

| with no load |

| 2. Defective rotor diode | 2. Replace both diodes on rotor |

| 3. Partial short circuit in winding | 3. Check resistance of coils (see ÒElectrical |

|

| Component Specifications,Ó page 2) |

| 4. Defective capacitor | 4. Replace capacitor |

|

|

|

Voltmeter reading more than | Engine speed too high | Set engine speed to 3720 RPM (62 Hz) |

10% high with no electrical |

| with no load |

load |

|

|

Voltmeter reading correct with no electrical load, but more than 10% low when electrical load is added

1. Defective rotor diode | 1. Replace both diodes on rotor |

2. Electrical load too high | 2. Do not overload generator |

3. Engine not running properly | 3. Contact an authorized engine service |

| center |

18