Dayton Operating Instructions and Parts Manual

Models 3WY47, 3W735B, 3W736C, 3WY44, 3TE27A, 3WY45, and 3WY46

Generator Features (Continued)

If RESET button does not pop out,

do not use the GFCI receptacle. Contact a qualified electrician for repairs.

2.If the GFCI receptacle tests okay, restore power by pushing the RESET button back in. The test lamp should work at this time.

IMPORTANT: You must press the RESET button firmly and fully. It should lock into place. If the GFCI does not lock into place, do not use receptacle. Contact a qualified electrician for repairs.

RESET

TEST

Figure 8 - GFCI Receptacle

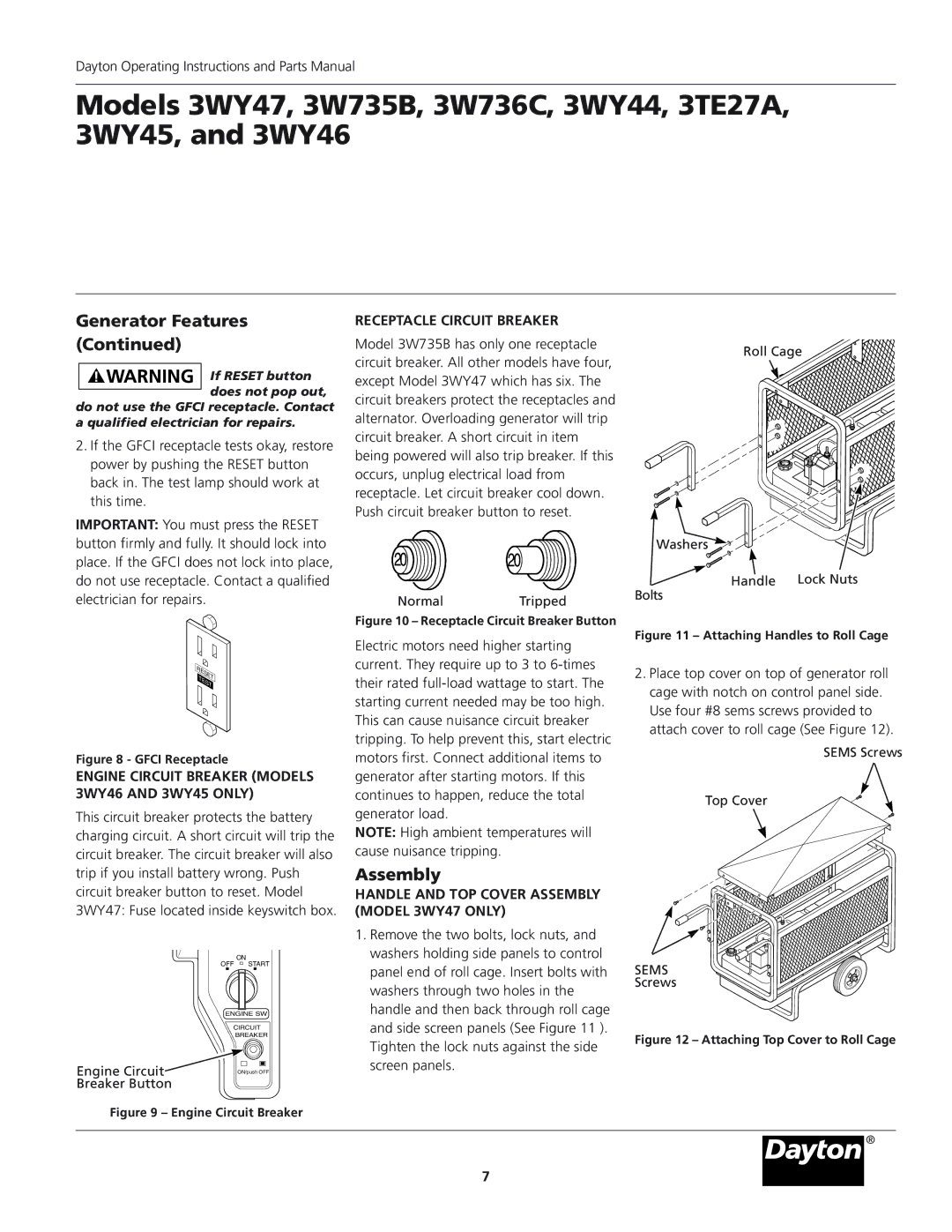

ENGINE CIRCUIT BREAKER (MODELS 3WY46 AND 3WY45 ONLY)

This circuit breaker protects the battery charging circuit. A short circuit will trip the circuit breaker. The circuit breaker will also trip if you install battery wrong. Push circuit breaker button to reset. Model 3WY47: Fuse located inside keyswitch box.

ON

OFF ![]() START

START

ENGINE SW

CIRCUIT

BREAKER

Engine Circuit![]() ON/push OFF

ON/push OFF

Breaker Button

RECEPTACLE CIRCUIT BREAKER

Model 3W735B has only one receptacle circuit breaker. All other models have four, except Model 3WY47 which has six. The circuit breakers protect the receptacles and alternator. Overloading generator will trip circuit breaker. A short circuit in item being powered will also trip breaker. If this occurs, unplug electrical load from receptacle. Let circuit breaker cool down. Push circuit breaker button to reset.

20 | 20 |

Normal | Tripped |

Figure 10 – Receptacle Circuit Breaker Button

Electric motors need higher starting current. They require up to 3 to

NOTE: High ambient temperatures will cause nuisance tripping.

Assembly

HANDLE AND TOP COVER ASSEMBLY (MODEL 3WY47 ONLY)

1.Remove the two bolts, lock nuts, and washers holding side panels to control panel end of roll cage. Insert bolts with washers through two holes in the handle and then back through roll cage and side screen panels (See Figure 11 ). Tighten the lock nuts against the side screen panels.

Roll Cage

Washers |

![]() Handle Lock Nuts Bolts

Handle Lock Nuts Bolts

Figure 11 – Attaching Handles to Roll Cage

2.Place top cover on top of generator roll cage with notch on control panel side. Use four #8 sems screws provided to attach cover to roll cage (See Figure 12).

SEMS Screws

Top Cover

SEMS

Screws

Figure 12 – Attaching Top Cover to Roll Cage

Figure 9 – Engine Circuit Breaker

®

7

Version B - For Reduction | G016.J |