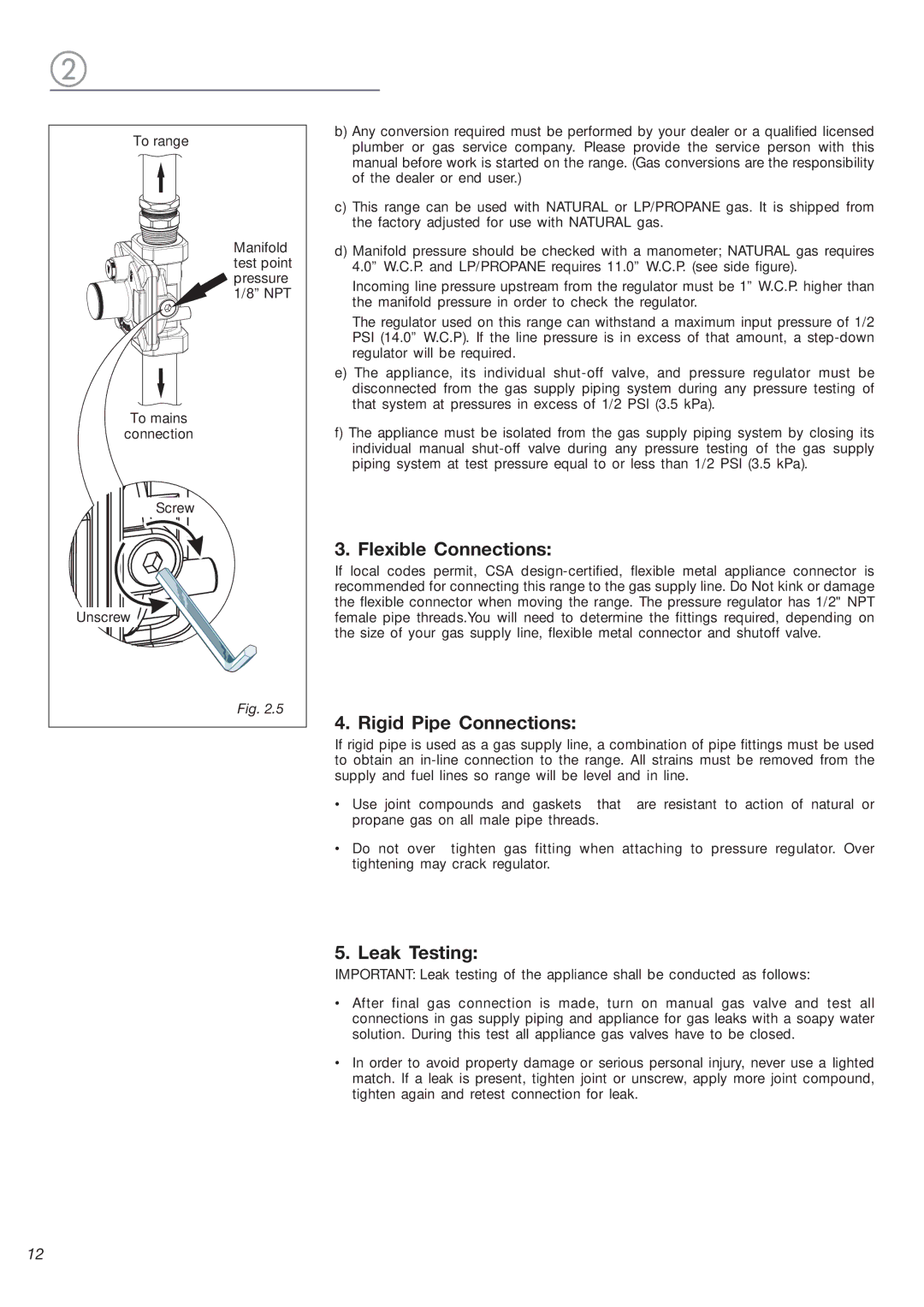

To range |

Manifold |

test point |

pressure |

1/8” NPT |

To mains |

connection |

Screw |

Unscrew |

Fig. 2.5 |

b)Any conversion required must be performed by your dealer or a qualified licensed plumber or gas service company. Please provide the service person with this manual before work is started on the range. (Gas conversions are the responsibility of the dealer or end user.)

c)This range can be used with NATURAL or LP/PROPANE gas. It is shipped from the factory adjusted for use with NATURAL gas.

d)Manifold pressure should be checked with a manometer; NATURAL gas requires 4.0” W.C.P. and LP/PROPANE requires 11.0” W.C.P. (see side figure).

Incoming line pressure upstream from the regulator must be 1” W.C.P. higher than the manifold pressure in order to check the regulator.

The regulator used on this range can withstand a maximum input pressure of 1/2 PSI (14.0” W.C.P). If the line pressure is in excess of that amount, a

e)The appliance, its individual

f)The appliance must be isolated from the gas supply piping system by closing its individual manual

3. Flexible Connections:

If local codes permit, CSA

4. Rigid Pipe Connections:

If rigid pipe is used as a gas supply line, a combination of pipe fittings must be used to obtain an

•Use joint compounds and gaskets that are resistant to action of natural or propane gas on all male pipe threads.

•Do not over tighten gas fitting when attaching to pressure regulator. Over tightening may crack regulator.

5. Leak Testing:

IMPORTANT: Leak testing of the appliance shall be conducted as follows:

•After final gas connection is made, turn on manual gas valve and test all connections in gas supply piping and appliance for gas leaks with a soapy water solution. During this test all appliance gas valves have to be closed.

•In order to avoid property damage or serious personal injury, never use a Iighted match. If a leak is present, tighten joint or unscrew, apply more joint compound, tighten again and retest connection for leak.

12