To change feed roll speeds, make sure the feed roll engagement lever (A) Fig. 12, is disengaged (in the down position) and open the left side door of the machine. When the belt (C) is on the smallest step of the motor pulley (D) and the largest step of the gearbox pulley (E), the feed roll speed will be 25 feet per minute. When the belt (C) is on the largest step of the motor pulley (D) and the smallest step of the gearbox pulley (E), the feed roll speed will be 46 feet per minute.

TABLE ROLLERS

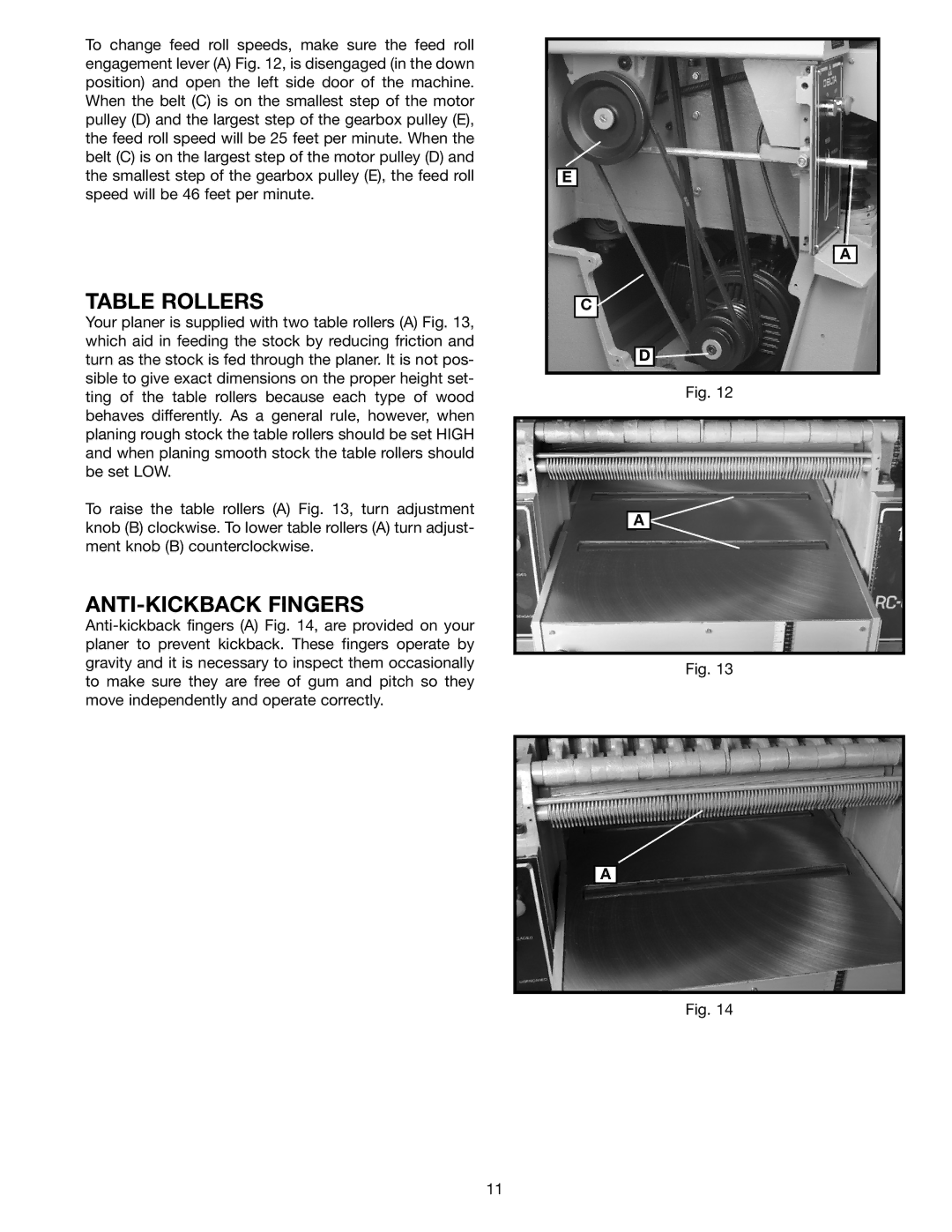

Your planer is supplied with two table rollers (A) Fig. 13, which aid in feeding the stock by reducing friction and turn as the stock is fed through the planer. It is not pos- sible to give exact dimensions on the proper height set- ting of the table rollers because each type of wood behaves differently. As a general rule, however, when planing rough stock the table rollers should be set HIGH and when planing smooth stock the table rollers should be set LOW.

To raise the table rollers (A) Fig. 13, turn adjustment knob (B) clockwise. To lower table rollers (A) turn adjust- ment knob (B) counterclockwise.

ANTI-KICKBACK FINGERS

E

A

C

D![]()

![]()

Fig. 12

A ![]()

Fig. 13

A

Fig. 14

11