ADJUSTMENTS

ADJUSTING THE TABLE TILT

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() For any bevel sanding operation, you must use a table insert with an

For any bevel sanding operation, you must use a table insert with an

work piece.

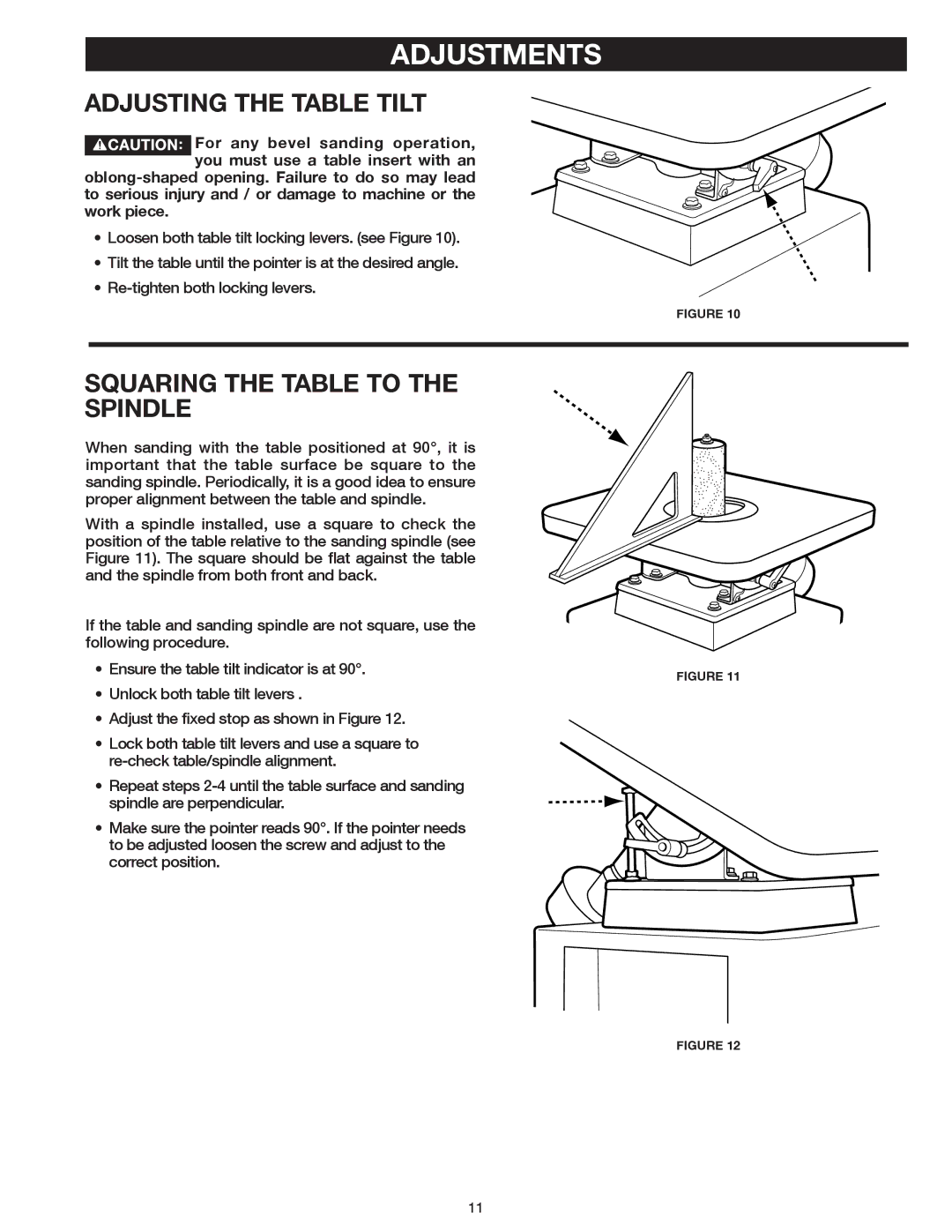

•Loosen both table tilt locking levers. (see Figure 10).

•Tilt the table until the pointer is at the desired angle.

•

Figure 10

SQUARING THE TABLE TO THE SPINDLE

When sanding with the table positioned at 90°, it is important that the table surface be square to the sanding spindle. Periodically, it is a good idea to ensure proper alignment between the table and spindle.

With a spindle installed, use a square to check the position of the table relative to the sanding spindle (see Figure 11). The square should be flat against the table and the spindle from both front and back.

If the table and sanding spindle are not square, use the following procedure.

•Ensure the table tilt indicator is at 90°.

•Unlock both table tilt levers .

•Adjust the fixed stop as shown in Figure 12.

•Lock both table tilt levers and use a square to

•Repeat steps

•Make sure the pointer reads 90°. If the pointer needs to be adjusted loosen the screw and adjust to the correct position.

Figure 11

Figure 12

11