36-545, 36-540 specifications

The Delta 36-540 and 36-545 are highly regarded table saws designed for precision, durability, and efficiency. These models are widely used by woodworkers, both hobbyists and professionals, and they offer advanced features that enhance cutting capabilities and overall user experience.One of the main features of the Delta 36-540 is its powerful 15-amp motor, which delivers ample torque and ensures that even the toughest hardwoods can be cut with ease. The motor is designed for smooth operation and minimal vibration, thereby enhancing accuracy during cutting tasks. The saw has a 10-inch blade that can reach impressive speeds, allowing for quick and clean cuts.

The Delta 36-545 model offers similar performance, but it comes with additional features that cater to more advanced users. Both models include a high-quality cast iron table, which provides a robust and stable surface for cutting. This construction helps reduce vibrations and increases the overall stability of the saw, ensuring precise cuts every time.

Both saws incorporate a patented blade-guard system, promoting safety in the workshop. This feature provides clear visibility of the cutting area while safeguarding the user from accidental blade contact. Additionally, the easy-to-use adjustment mechanisms allow users to modify blade height and angle quickly, simplifying the setup process for different cutting applications.

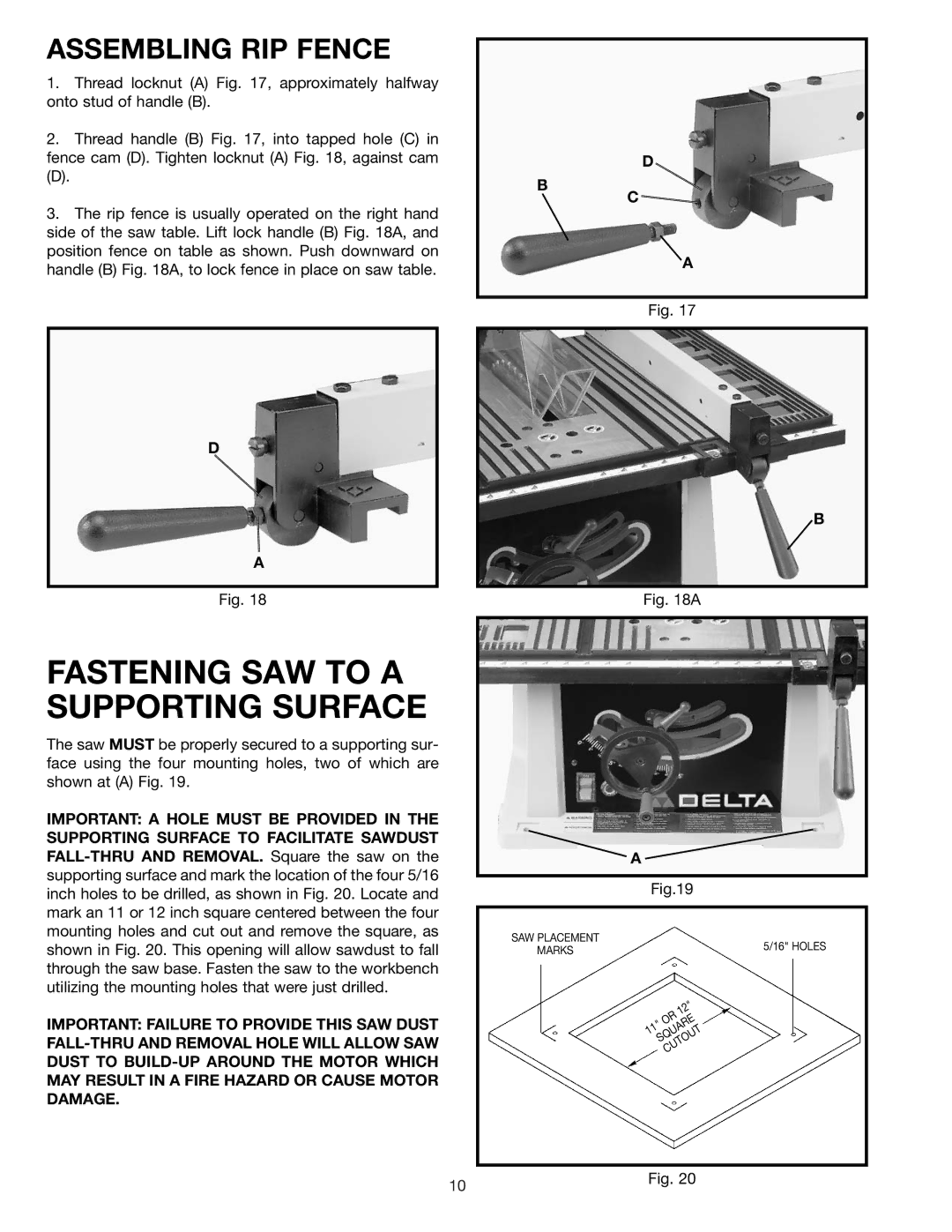

Another significant aspect of the Delta 36-540 and 36-545 is their fence systems. They come equipped with a reliable and adjustable fence that locks firmly in place, ensuring consistent and straight cuts. The alignment and precision of the fence save time during setup and provide users with confidence in their cuts.

Portability is also a key element in both models, with foldable stands that allow for easy transport and storage. Users can take their saws to job sites or store them away conveniently when not in use.

In summary, the Delta 36-540 and 36-545 table saws combine power, precision, and safety features designed to enhance the woodworking experience. With their robust construction, user-friendly adjustments, and advanced safety measures, these saws are an excellent choice for any woodworker looking for a reliable and efficient tool. Whether for professional use or personal projects, both models deliver exceptional performance, making them a staple in the woodworking community.