ASSEMBLING SUPPORT TUBE A N D M O TO R A N D B L O W E R ASSEMBLY TO BASE

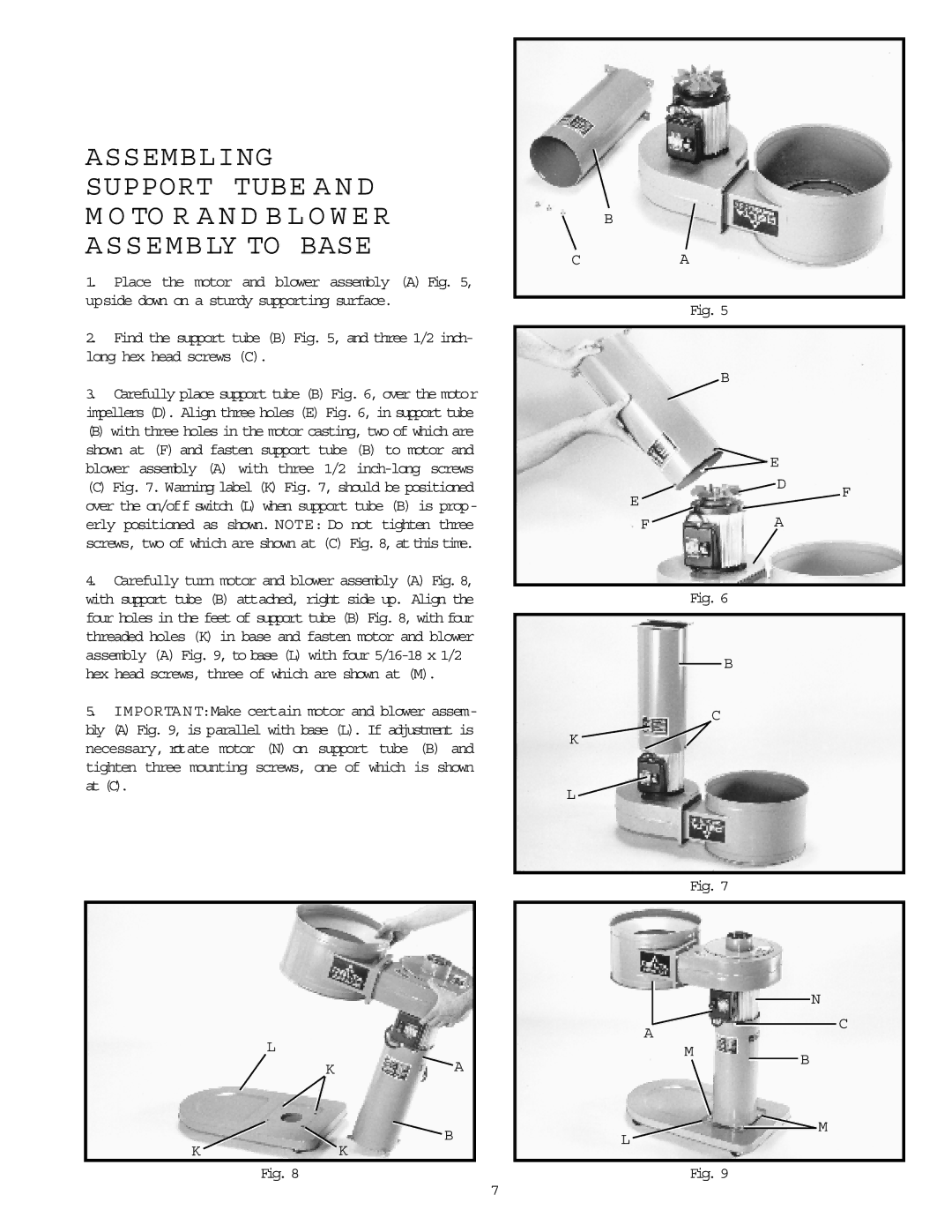

1. | Place the motor and blower assembly (A) Fig. 5, |

upside down on a sturdy supporting surface. | |

2. | Find the support tube (B) Fig. 5, and three 1/2 inch- |

long hex head screws (C). | |

3. | Carefully place support tube (B) Fig. 6, over the motor |

impellers (D). Align three holes (E) Fig. 6, in support tube | |

(B) with three holes in the motor casting, two of which are | |

shown at (F) and fasten support tube (B) to motor and | |

blower assembly (A) with three 1/2 | |

(C) Fig. 7. Warning label (K) Fig. 7, should be positioned | |

B

CA

Fig. 5

B

![]() E

E

D

over the on/off switch (L) when support tube (B) is prop- |

E

F

erly positioned as shown. NOTE: Do not tighten three |

screws, two of which are shown at (C) Fig. 8, at this time. |

4. Carefully turn motor and blower assembly (A) Fig. 8, |

with support tube (B) attached, right side up. Align the |

four holes in the feet of support tube (B) Fig. 8, with four |

threaded holes (K) in base and fasten motor and blower |

assembly (A) Fig. 9, to base (L) with four |

hex head screws, three of which are shown at (M). |

5. IMPORTANT:Make certain motor and blower assem- |

bly (A) Fig. 9, is parallel with base (L). If adjustment is |

necessary, rotate motor (N) on support tube (B) and |

tighten three mounting screws, one of which is shown |

at (C). |

F ![]() A

A

Fig. 6

B

C

K ![]()

L ![]()

Fig. 7

N

A

C

L

K ![]() A

A

![]() B

B

KK

Fig. 8

M

B

![]() M

M

L

Fig. 9

7