OPERATION

Your drill press is to be used with drill bits of 1/2" or less in diameter. The following will give the inexperienced operator a start on common drill press operations. Use scrap material for practice to get a feel of the machine before attempting regular work.

![]() WARNING: The use of accessories and attachments not recommended by Delta may result in risk of injury.

WARNING: The use of accessories and attachments not recommended by Delta may result in risk of injury.

INSTALLING AND REMOVING DRILL BITS

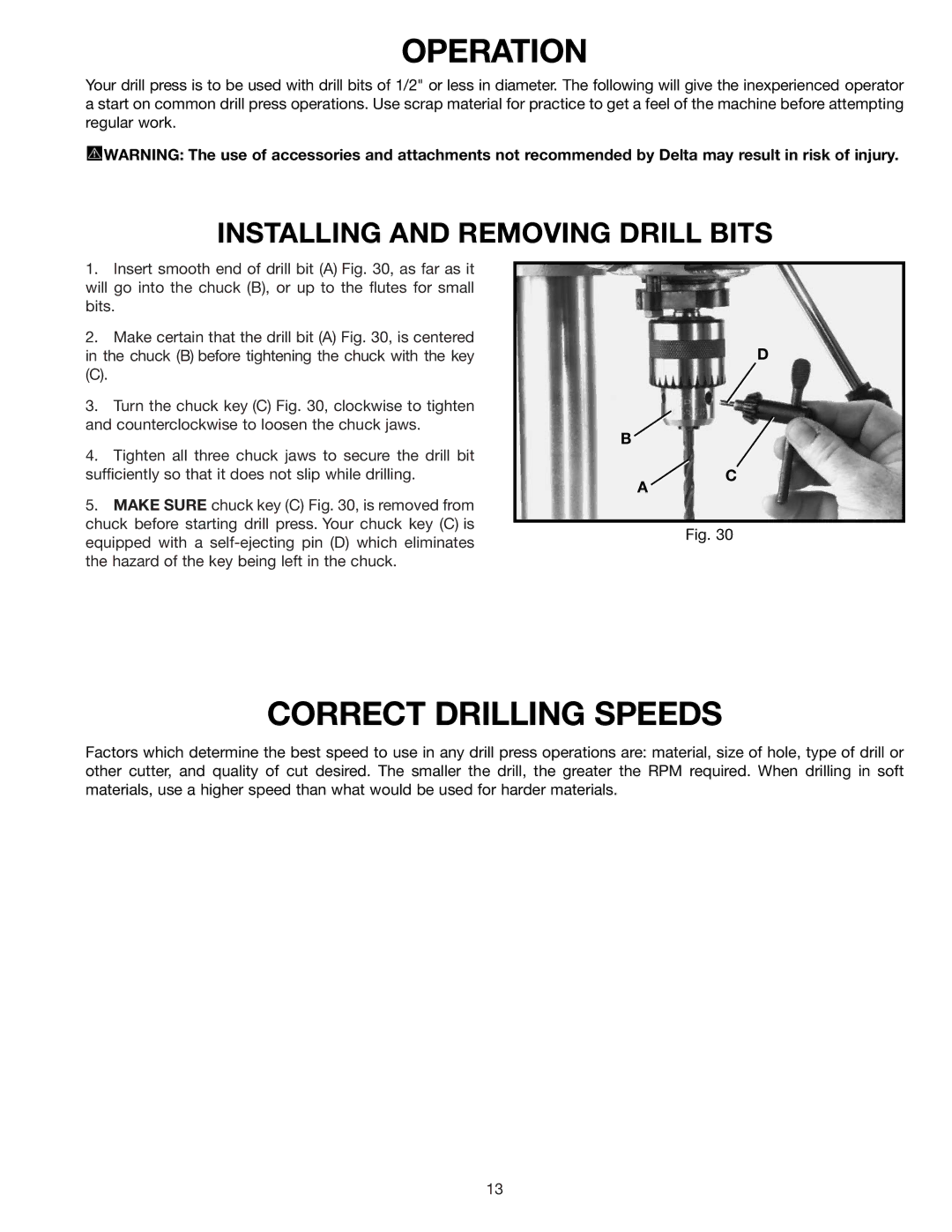

1.Insert smooth end of drill bit (A) Fig. 30, as far as it will go into the chuck (B), or up to the flutes for small bits.

2.Make certain that the drill bit (A) Fig. 30, is centered in the chuck (B) before tightening the chuck with the key

(C).

3.Turn the chuck key (C) Fig. 30, clockwise to tighten and counterclockwise to loosen the chuck jaws.

4.Tighten all three chuck jaws to secure the drill bit sufficiently so that it does not slip while drilling.

5.MAKE SURE chuck key (C) Fig. 30, is removed from chuck before starting drill press. Your chuck key (C) is equipped with a

D

B

C

A

Fig. 30

CORRECT DRILLING SPEEDS

Factors which determine the best speed to use in any drill press operations are: material, size of hole, type of drill or other cutter, and quality of cut desired. The smaller the drill, the greater the RPM required. When drilling in soft materials, use a higher speed than what would be used for harder materials.

13