Q48DR specifications

Delta Electronics has established a significant presence in the power supply industry, and its Q48DR series of DC-DC converters is a testament to the company's commitment to innovation and reliability. The Q48DR series is specifically designed to cater to various applications, particularly in telecommunications and industrial sectors, where compactness and efficiency are paramount.One of the standout features of the Q48DR is its wide input voltage range, typically from 36V to 75V. This flexibility allows the converter to accommodate various input sources, ensuring robust performance in diverse applications. The output voltage options are also customizable, making the Q48DR highly adaptable to specific operational needs.

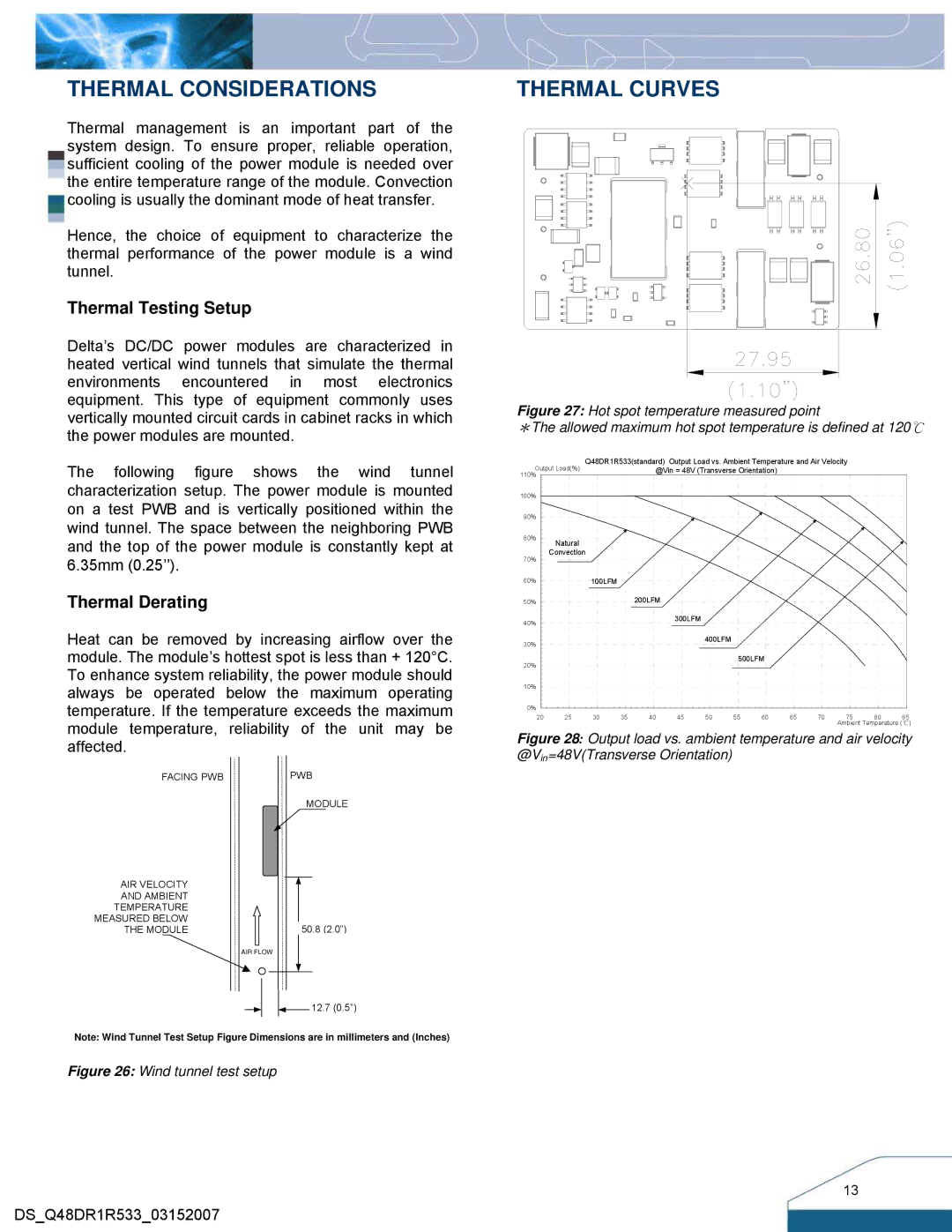

Efficiency is a critical characteristic of the Q48DR, with typical efficiencies reaching up to 92%. This high level of efficiency translates to reduced operational costs and lower heat generation, which is crucial for maintaining system reliability and longevity. The design emphasizes thermal management, featuring a compact footprint that facilitates efficient heat dissipation.

The Q48DR series employs advanced power management technologies, including synchronous rectification. This technology reduces switching loss, further enhancing the overall efficiency of the converter. Additionally, the integrated over-voltage, over-current, and thermal protection mechanisms ensure that the device operates safely under varying conditions, prolonging its lifespan and protecting connected components.

Another notable aspect of the Q48DR is its compact, lightweight design. Typically measuring just a few inches, the small size makes it suitable for space-constrained applications without compromising on power output. Furthermore, the device is built with a rugged construction that meets the stringent demands of industrial environments, ensuring reliable performance even in harsh conditions.

The Q48DR series is also equipped with remote sense capabilities. This feature allows for precise voltage regulation at the load, compensating for any voltage drop across the distribution cable. This ensures that the end application receives the voltage it requires without fluctuations, thereby enhancing overall system performance.

With its blend of efficiency, advanced protection features, and compact design, the Delta Electronics Q48DR is an exemplary DC-DC converter that meets the critical demands of modern applications. Whether for telecom infrastructure, industrial automation, or other high-performance environments, the Q48DR series stands out as a versatile and reliable choice for engineers seeking effective power solutions.