®BDV34NA AND BDV34PA

DIRECT-VENT FIREPLACE (NATURAL/PROPANE/LP)

INSPECTING

BURNERS

Continued

BURNER FLAME PATTERN

Burner flames will be steady; not lifting or floating. Flame patterns will be different from unit to unit and will vary depending on installation type and weather conditions.

If the vent configuration is installed incor- rectly, the flames will lift or "ghost". This can be dangerous. Inspect the flames after installation to ensure proper installation and performance.

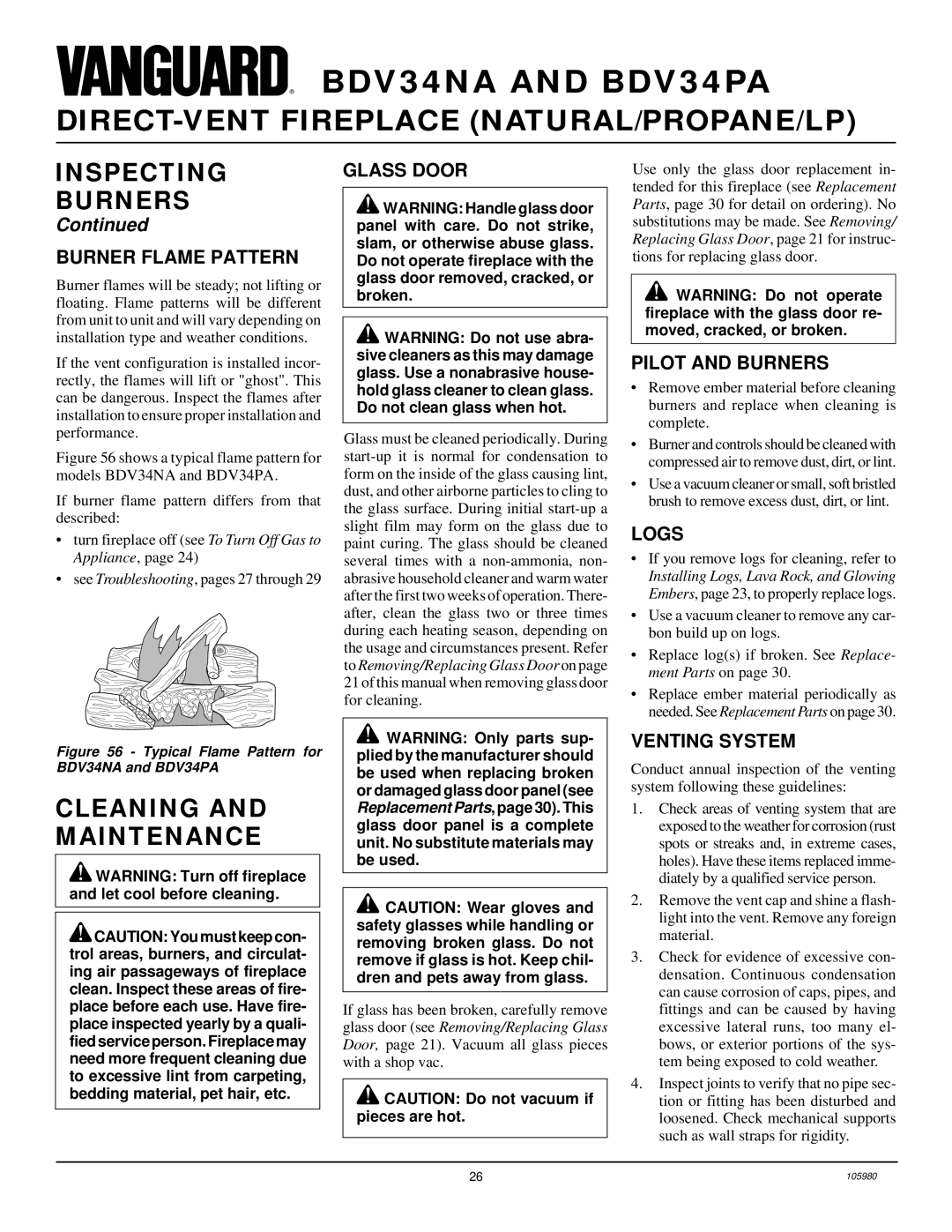

Figure 56 shows a typical flame pattern for models BDV34NA and BDV34PA.

If burner flame pattern differs from that described:

•turn fireplace off (seeTo Turn Off Gas to Appliance, page 24)

•seeTroubleshooting, pages 27 through 29

Figure 56 - Typical Flame Pattern for BDV34NA and BDV34PA

CLEANING AND MAINTENANCE

![]() WARNING: Turn off fireplace and let cool before cleaning.

WARNING: Turn off fireplace and let cool before cleaning.

![]() CAUTION: You must keep con- trol areas, burners, and circulat- ing air passageways of fireplace clean. Inspect these areas of fire- place before each use. Have fire- place inspected yearly by a quali- fied service person. Fireplace may need more frequent cleaning due to excessive lint from carpeting, bedding material, pet hair, etc.

CAUTION: You must keep con- trol areas, burners, and circulat- ing air passageways of fireplace clean. Inspect these areas of fire- place before each use. Have fire- place inspected yearly by a quali- fied service person. Fireplace may need more frequent cleaning due to excessive lint from carpeting, bedding material, pet hair, etc.

GLASS DOOR

![]() WARNING: Handle glass door panel with care. Do not strike, slam, or otherwise abuse glass. Do not operate fireplace with the glass door removed, cracked, or broken.

WARNING: Handle glass door panel with care. Do not strike, slam, or otherwise abuse glass. Do not operate fireplace with the glass door removed, cracked, or broken.

![]() WARNING: Do not use abra- sive cleaners as this may damage glass. Use a nonabrasive house- hold glass cleaner to clean glass. Do not clean glass when hot.

WARNING: Do not use abra- sive cleaners as this may damage glass. Use a nonabrasive house- hold glass cleaner to clean glass. Do not clean glass when hot.

Glass must be cleaned periodically. During

![]() WARNING: Only parts sup- plied by the manufacturer should be used when replacing broken or damaged glass door panel (see Replacement Parts, page 30). This glass door panel is a complete unit. No substitute materials may be used.

WARNING: Only parts sup- plied by the manufacturer should be used when replacing broken or damaged glass door panel (see Replacement Parts, page 30). This glass door panel is a complete unit. No substitute materials may be used.

![]() CAUTION: Wear gloves and safety glasses while handling or removing broken glass. Do not remove if glass is hot. Keep chil- dren and pets away from glass.

CAUTION: Wear gloves and safety glasses while handling or removing broken glass. Do not remove if glass is hot. Keep chil- dren and pets away from glass.

If glass has been broken, carefully remove glass door (see Removing/Replacing Glass Door, page 21). Vacuum all glass pieces with a shop vac.

![]() CAUTION: Do not vacuum if pieces are hot.

CAUTION: Do not vacuum if pieces are hot.

Use only the glass door replacement in- tended for this fireplace (see Replacement Parts, page 30 for detail on ordering). No substitutions may be made. See Removing/ Replacing Glass Door, page 21 for instruc- tions for replacing glass door.

![]() WARNING: Do not operate fireplace with the glass door re- moved, cracked, or broken.

WARNING: Do not operate fireplace with the glass door re- moved, cracked, or broken.

PILOT AND BURNERS

•Remove ember material before cleaning burners and replace when cleaning is complete.

•Burner and controls should be cleaned with compressed air to remove dust, dirt, or lint.

•Use a vacuum cleaner or small, soft bristled brush to remove excess dust, dirt, or lint.

LOGS

•If you remove logs for cleaning, refer to Installing Logs, Lava Rock, and Glowing Embers, page 23, to properly replace logs.

•Use a vacuum cleaner to remove any car- bon build up on logs.

•Replace log(s) if broken. See Replace- ment Parts on page 30.

•Replace ember material periodically as needed. See Replacement Parts on page 30.

VENTING SYSTEM

Conduct annual inspection of the venting system following these guidelines:

1.Check areas of venting system that are exposed to the weather for corrosion (rust spots or streaks and, in extreme cases, holes). Have these items replaced imme- diately by a qualified service person.

2.Remove the vent cap and shine a flash- light into the vent. Remove any foreign material.

3.Check for evidence of excessive con- densation. Continuous condensation can cause corrosion of caps, pipes, and fittings and can be caused by having excessive lateral runs, too many el- bows, or exterior portions of the sys- tem being exposed to cold weather.

4.Inspect joints to verify that no pipe sec- tion or fitting has been disturbed and loosened. Check mechanical supports such as wall straps for rigidity.

26 | 105980 |