Wood Burning Fireplace specifications

The Desa Wood Burning Fireplace stands as a timeless centerpiece that combines the beauty of traditional wood-burning aesthetics with innovative heating technology. Designed to enhance both the ambiance and comfort of any home, this fireplace offers an extensive range of features tailored to meet modern needs while respecting classic traditions.One of the standout features of the Desa Wood Burning Fireplace is its robust construction. Crafted from high-quality materials, it ensures durability and longevity, making it a reliable choice for homeowners looking for a long-term investment. Its design incorporates high-efficiency combustion technology, which maximizes heat output while minimizing smoke emissions. This eco-friendly approach not only supports a cleaner burning experience but also reduces the frequency of refueling.

The fireplace boasts a spacious firebox that accommodates larger logs, allowing for longer burn times and less frequent refilling. This feature is particularly advantageous during those cold winter nights, as it provides a consistent and comforting heat source. The adjustable air control system further enhances this experience, enabling users to regulate the burn rate and heat intensity according to their preferences.

Another notable characteristic of the Desa Wood Burning Fireplace is its versatility in design options. Available in a variety of styles, from classic to contemporary, it can seamlessly integrate into any home decor. The glass door options not only provide a stunning view of the flames but also enhance safety by keeping embers contained. Additionally, the fireplace comes with customizable mantels and surrounds that allow homeowners to create a personalized look that fits their unique taste.

Ease of installation is another key benefit of the Desa Wood Burning Fireplace. Designed with user-friendly features, it can be conveniently installed in both new constructions and existing homes. This adaptability makes it an excellent choice for those looking to upgrade their existing heating systems.

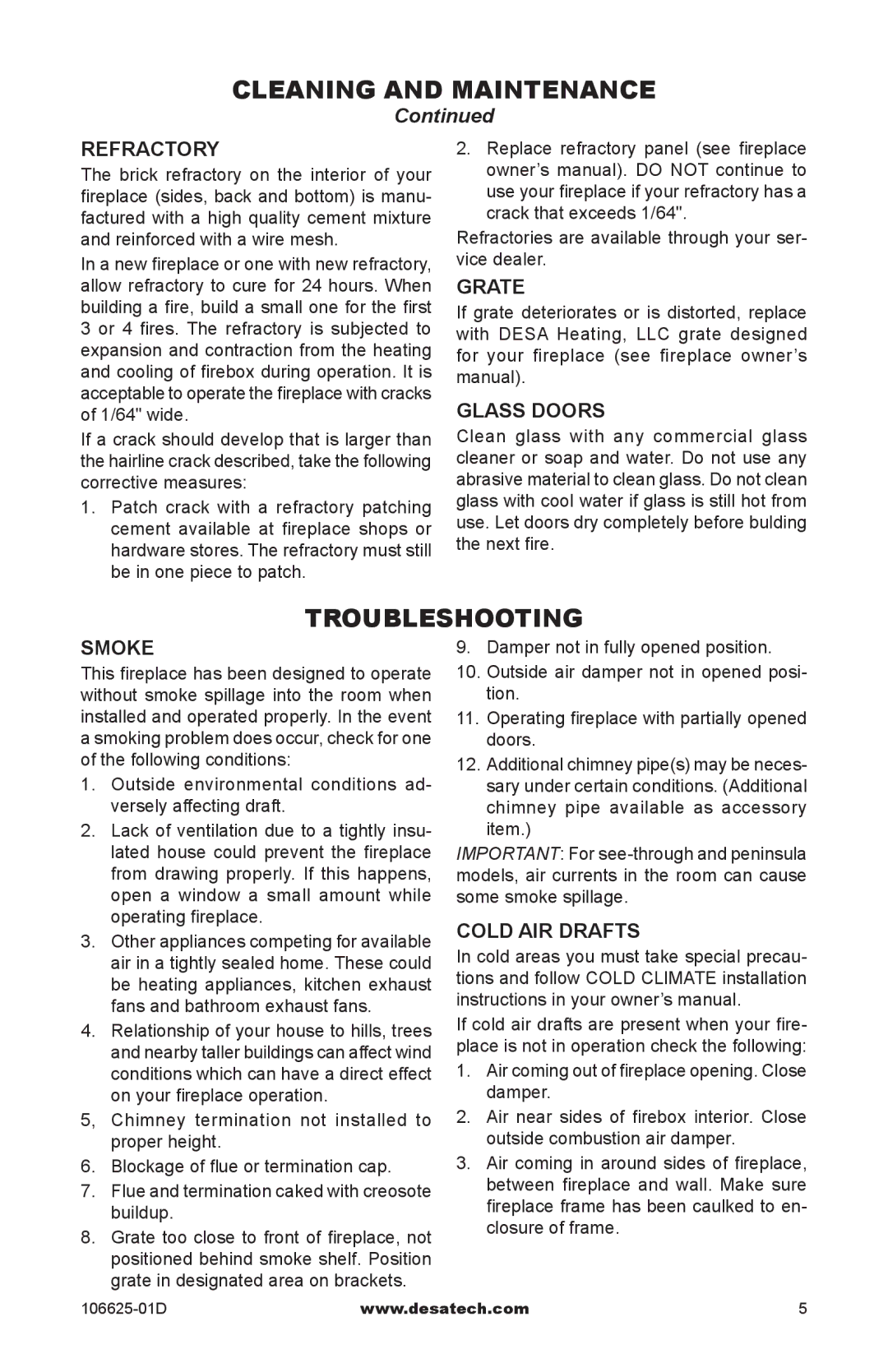

In terms of maintenance, the Desa Wood Burning Fireplace requires minimal effort. With a straightforward cleaning process and easy access to the ash pan, keeping the fireplace in optimal condition becomes a hassle-free task.

In summary, the Desa Wood Burning Fireplace combines durability, efficiency, and aesthetic appeal, making it an exceptional choice for homeowners seeking a reliable heating solution. With its innovative technologies and customizable features, it stands out as a perfect blend of tradition and modern functionality, creating warm and inviting spaces for years to come.