ASSEMBLY (does not apply to all units)

Some models require no assembly. If your unit requires assembly, match the instructions below to your unit.

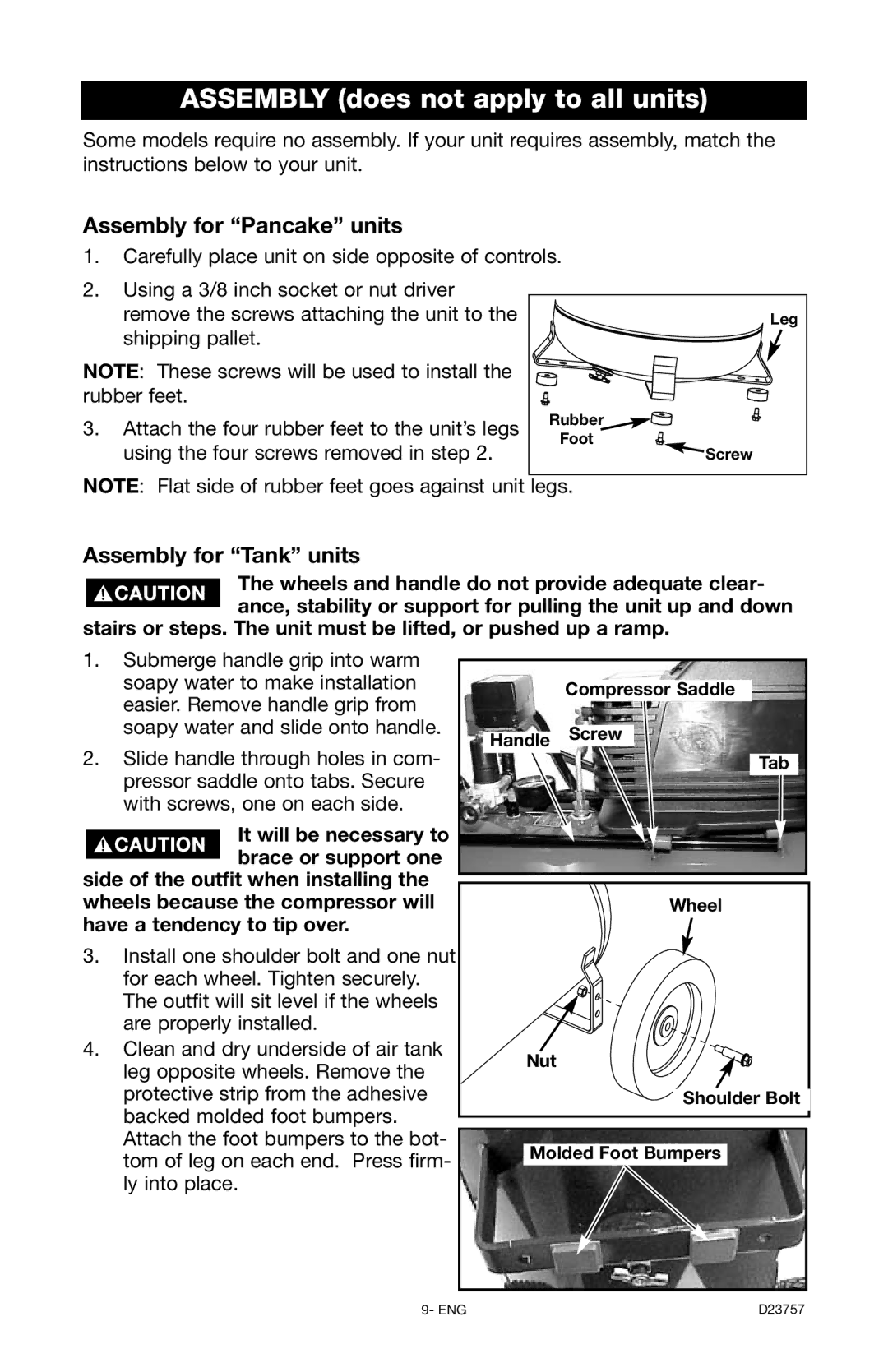

Assembly for “Pancake” units

1.Carefully place unit on side opposite of controls.

2.Using a 3/8 inch socket or nut driver remove the screws attaching the unit to the shipping pallet.

NOTE: These screws will be used to install the rubber feet.

3.Attach the four rubber feet to the unit’s legs using the four screws removed in step 2.

Leg |

Rubber |

Foot |

Screw |

NOTE: Flat side of rubber feet goes against unit legs.

Assembly for “Tank” units

The wheels and handle do not provide adequate clear- ance, stability or support for pulling the unit up and down

stairs or steps. The unit must be lifted, or pushed up a ramp.

1.Submerge handle grip into warm soapy water to make installation easier. Remove handle grip from soapy water and slide onto handle.

2.Slide handle through holes in com- pressor saddle onto tabs. Secure with screws, one on each side.

It will be necessary to brace or support one

side of the outfit when installing the wheels because the compressor will have a tendency to tip over.

3.Install one shoulder bolt and one nut for each wheel. Tighten securely. The outfit will sit level if the wheels are properly installed.

4.Clean and dry underside of air tank leg opposite wheels. Remove the protective strip from the adhesive backed molded foot bumpers. Attach the foot bumpers to the bot- tom of leg on each end. Press firm- ly into place.

Compressor Saddle

Handle Screw

Tab

Wheel |

Nut |

Shoulder Bolt |

Molded Foot Bumpers

9- ENG | D23757 |