Page 8 |

|

|

|

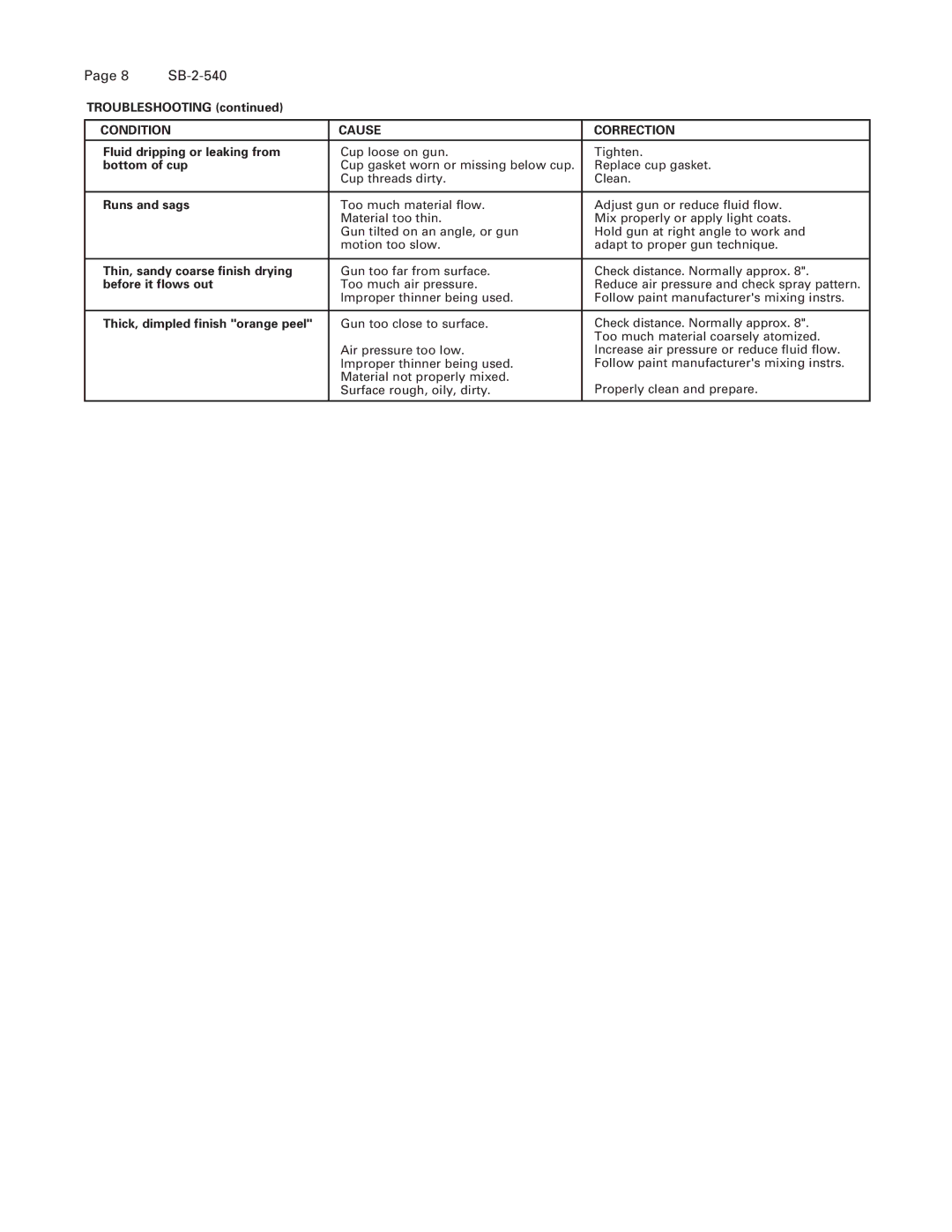

TROUBLESHOOTING (continued) |

|

| |

|

|

| |

CONDITION | CAUSE | CORRECTION | |

|

|

| |

Fluid dripping or leaking from | Cup loose on gun. | Tighten. | |

bottom of cup | Cup gasket worn or missing below cup. | Replace cup gasket. | |

|

| Cup threads dirty. | Clean. |

|

|

| |

Runs and sags | Too much material flow. | Adjust gun or reduce fluid flow. | |

|

| Material too thin. | Mix properly or apply light coats. |

|

| Gun tilted on an angle, or gun | Hold gun at right angle to work and |

|

| motion too slow. | adapt to proper gun technique. |

|

|

| |

Thin, sandy coarse finish drying | Gun too far from surface. | Check distance. Normally approx. 8". | |

before it flows out | Too much air pressure. | Reduce air pressure and check spray pattern. | |

|

| Improper thinner being used. | Follow paint manufacturer's mixing instrs. |

|

|

| |

Thick, dimpled finish "orange peel" | Gun too close to surface. | Check distance. Normally approx. 8". | |

|

|

| Too much material coarsely atomized. |

|

| Air pressure too low. | Increase air pressure or reduce fluid flow. |

|

| Improper thinner being used. | Follow paint manufacturer's mixing instrs. |

|

| Material not properly mixed. | Properly clean and prepare. |

|

| Surface rough, oily, dirty. | |

|

|

|

|

Page 8

Image 8