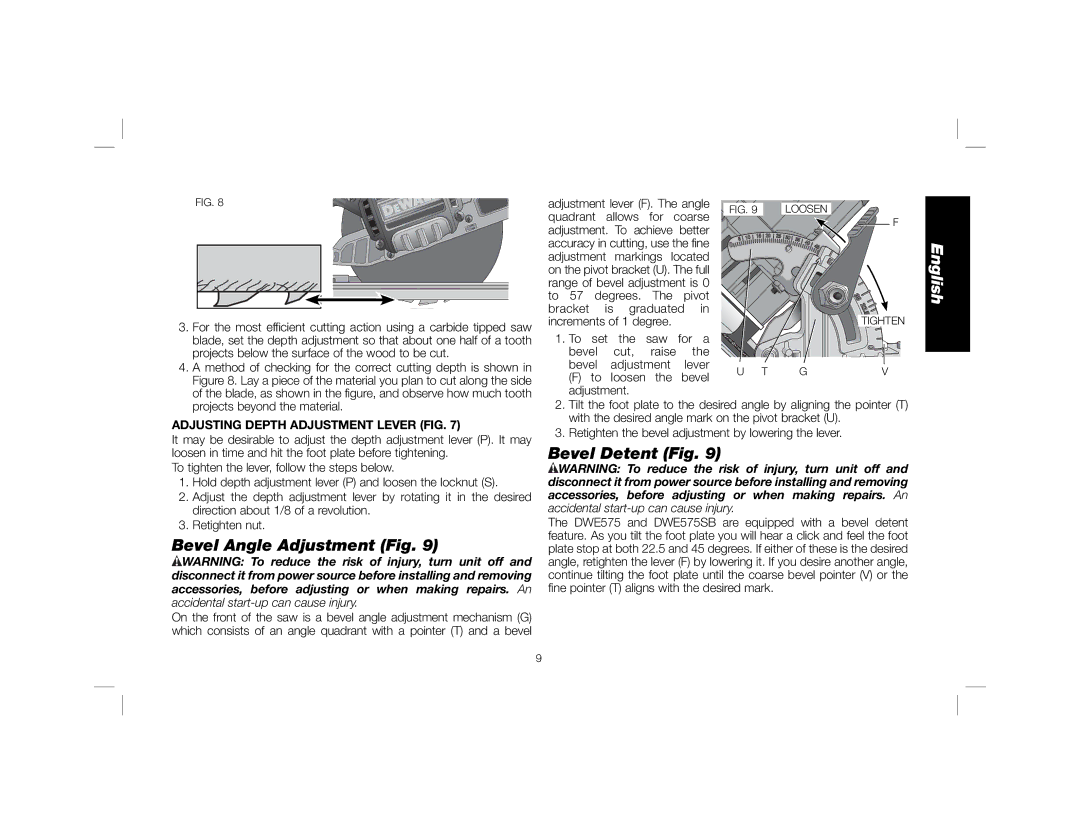

FIG. 8 | adjustment lever (F). The angle | FIG. 9 | LOOSEN |

| ||||||

| quadrant | allows | for | coarse | F | |||||

|

|

| ||||||||

| adjustment. To achieve | better |

|

| ||||||

|

|

|

| |||||||

| accuracy in cutting, use the fine |

|

|

| ||||||

| adjustment | markings | located |

|

|

| ||||

| on the pivot bracket (U). The full |

|

|

| ||||||

| range of bevel adjustment is 0 |

|

|

| ||||||

| to 57 degrees. The pivot |

|

|

| ||||||

| bracket | is | graduated | in |

|

|

| |||

3. For the most efficient cutting action using a carbide tipped saw | increments of 1 degree. |

|

|

|

| TIGHTEN | ||||

1. To set | the | saw |

| for | a |

|

|

| ||

blade, set the depth adjustment so that about one half of a tooth |

|

|

|

| ||||||

projects below the surface of the wood to be cut. | bevel |

| cut, | raise |

| the |

|

|

| |

4. A method of checking for the correct cutting depth is shown in | bevel | adjustment |

| lever | U T | G | V | |||

Figure 8. Lay a piece of the material you plan to cut along the side | (F) to loosen the bevel |

|

|

| ||||||

of the blade, as shown in the figure, and observe how much tooth | adjustment. |

|

|

|

|

|

|

| ||

projects beyond the material. | 2. Tilt the foot plate to the desired angle by aligning the pointer (T) | |||||||||

ADJUSTING DEPTH ADJUSTMENT LEVER (FIG. 7) | with the desired angle mark on the pivot bracket (U). |

| ||||||||

3. Retighten the bevel adjustment by lowering the lever. |

| |||||||||

It may be desirable to adjust the depth adjustment lever (P). It may |

| |||||||||

Bevel Detent (Fig. 9) |

|

|

| |||||||

loosen in time and hit the foot plate before tightening. |

|

|

| |||||||

To tighten the lever, follow the steps below. | WARNING: To reduce the risk of injury, turn unit off and | |||||||||

1.Hold depth adjustment lever (P) and loosen the locknut (S). disconnect it from power source before installing and removing

2. Adjust the depth adjustment lever by rotating it in the desired | accessories, before adjusting or when making repairs. An |

direction about 1/8 of a revolution. | accidental |

3. Retighten nut. | The DWE575 and DWE575SB are equipped with a bevel detent |

Bevel Angle Adjustment (Fig. 9) | feature. As you tilt the foot plate you will hear a click and feel the foot |

plate stop at both 22.5 and 45 degrees. If either of these is the desired | |

WARNING: To reduce the risk of injury, turn unit off and | angle, retighten the lever (F) by lowering it. If you desire another angle, |

disconnect it from power source before installing and removing | continue tilting the foot plate until the coarse bevel pointer (V) or the |

accessories, before adjusting or when making repairs. An | fine pointer (T) aligns with the desired mark. |

accidental |

|

On the front of the saw is a bevel angle adjustment mechanism (G) |

|

which consists of an angle quadrant with a pointer (T) and a bevel |

|

9

English