Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun trigger may be caused by excessive pump pressure. The principal cause of excessive pump pressure is a spray tip clogged or restricted with foreign materials, such as dirt, etc. To correct the problem, immediately clean the spray tip following these instructions:

1.Shut off engine and turn off water supply.

2.ALWAYS point spray gun in a safe direction, press red button and squeeze spray gun trigger to release retained high water pressure.

![]() WARNING

WARNING

The high pressure stream of water that this equipment produces can cut through skin and its underlying tissues, leading to serious injury and possible amputation.

Spray gun traps high water pressure, even when engine is stopped and water is disconnected, which can cause injury.

•Keep high pressure hose connected to pump and spray gun while system is pressurized.

•ALWAYS point spray gun in safe direction, press red button and squeeze spray gun trigger, to release high pressure, every time you stop engine.

3.Remove spray tip from end of nozzle extension.

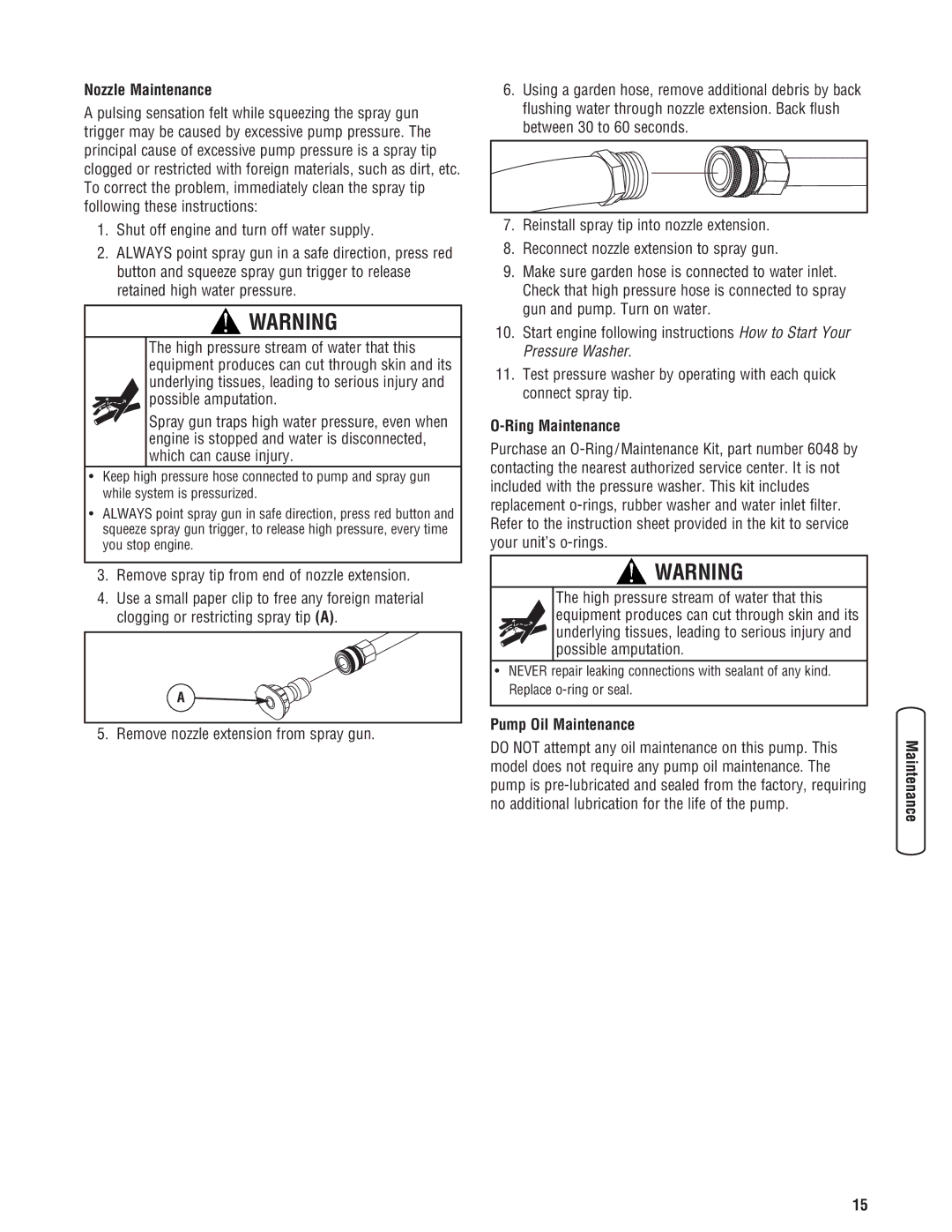

4.Use a small paper clip to free any foreign material clogging or restricting spray tip (A).

A![]()

![]()

![]()

5.Remove nozzle extension from spray gun.

6.Using a garden hose, remove additional debris by back flushing water through nozzle extension. Back flush between 30 to 60 seconds.

7.Reinstall spray tip into nozzle extension.

8.Reconnect nozzle extension to spray gun.

9.Make sure garden hose is connected to water inlet. Check that high pressure hose is connected to spray gun and pump. Turn on water.

10.Start engine following instructions How to Start Your Pressure Washer.

11.Test pressure washer by operating with each quick connect spray tip.

O-Ring Maintenance

Purchase an

![]() WARNING

WARNING

The high pressure stream of water that this equipment produces can cut through skin and its underlying tissues, leading to serious injury and possible amputation.

•NEVER repair leaking connections with sealant of any kind. Replace

Pump Oil Maintenance

DO NOT attempt any oil maintenance on this pump. This model does not require any pump oil maintenance. The pump is

15