2.Power supply connection

Check that the supply voltage details on the heater are in accordance with your electricity supply. A 2.5 metre length of

a.) Remote Control Switch Panel

Determine desired position for remote control switch panel above work bench i.e. 900mm minimum above floor level. It is designed for use with either a surface mounted or flush mounted box as listed in the Table opposite. The left hand column of the Table indicates the type of conduit/trunking required, if any, and the right hand column indicates the corresponding two gang box for the control switch panel. Fix the chosen mounting box in position.

b.) Electrical Connection to Remote Control Panel

Strip back the outer sheath of the

Flush or Surface | Two Gang box for | |||

Mounting | Remote Control Switch | |||

Conduit/Trunking | MK Switches | |||

|

|

|

| |

1. | Embedded – Rounded | 1. | MK 892 ALM (Metal) | |

| or oval conduit | 2. | Marshall Tufflex MSSB | |

2. | Surface Mounting mini- | |||

| 16 (PVC White) | |||

| trunking |

|

| |

3. | Surface Mounting – | 3. | MK 2142 WHI (White | |

| Moulded) | |||

| Cable clipped to wall |

|

| |

4. | DryLining Box | 4. | Marshall Tufflex MDLB | |

| 2 (Plastic) | |||

|

|

| ||

|

|

|

| |

If the 2.5 metre length of cable supplied is insufficient and a substitute cable is used, Ensure that the conductors are of minimum 1.5mm²

c.) Electrical Connection to Appliance

Remove the screws securing the top, front and rear covers in order to gain access to the terminal block. Feed the 6 core flexible

3.Fitting the Rear Support Bracket

The heater is supplied with a rear support bracket. Fit to the back of the appliance with the two screws supplied. Adjust the rear support bracket so that the vertical distance from the underside of the appliance to bottom of the rear support bracket equals the vertical distance from the floor in the cupboard space to the bottom of the aperture opening. The slots in the rear support bracket allow it to be adjusted to the required height.

4.Marking the Fixing Positions

Slide the heater into position in the plinth aperture. Mark the six fixing holes (two on each side and two on the top Remove the heater and drill 2mm pilot holes.

5.Mounting the Heater into the Plinth

When the cable connection has been made and the rear support bracket adjusted, slide the heater into the aperture ensuring that it is adequately supported and that the inlet grille is not obstructed. Use the six screws provided to secure the heater to the plinth. (See point 6 below for stainless steel grill fitting).

6.Stainless Steel Grille (BFH24RS model only).

The stainless steel grille is supplied (in the plastic covering) as an attachment for the front of the heater.

This should be offered up to the front of the heater before fixing the heater to the plinth. Use the six screws to secure it to the front of the heater / plinth.

Operation

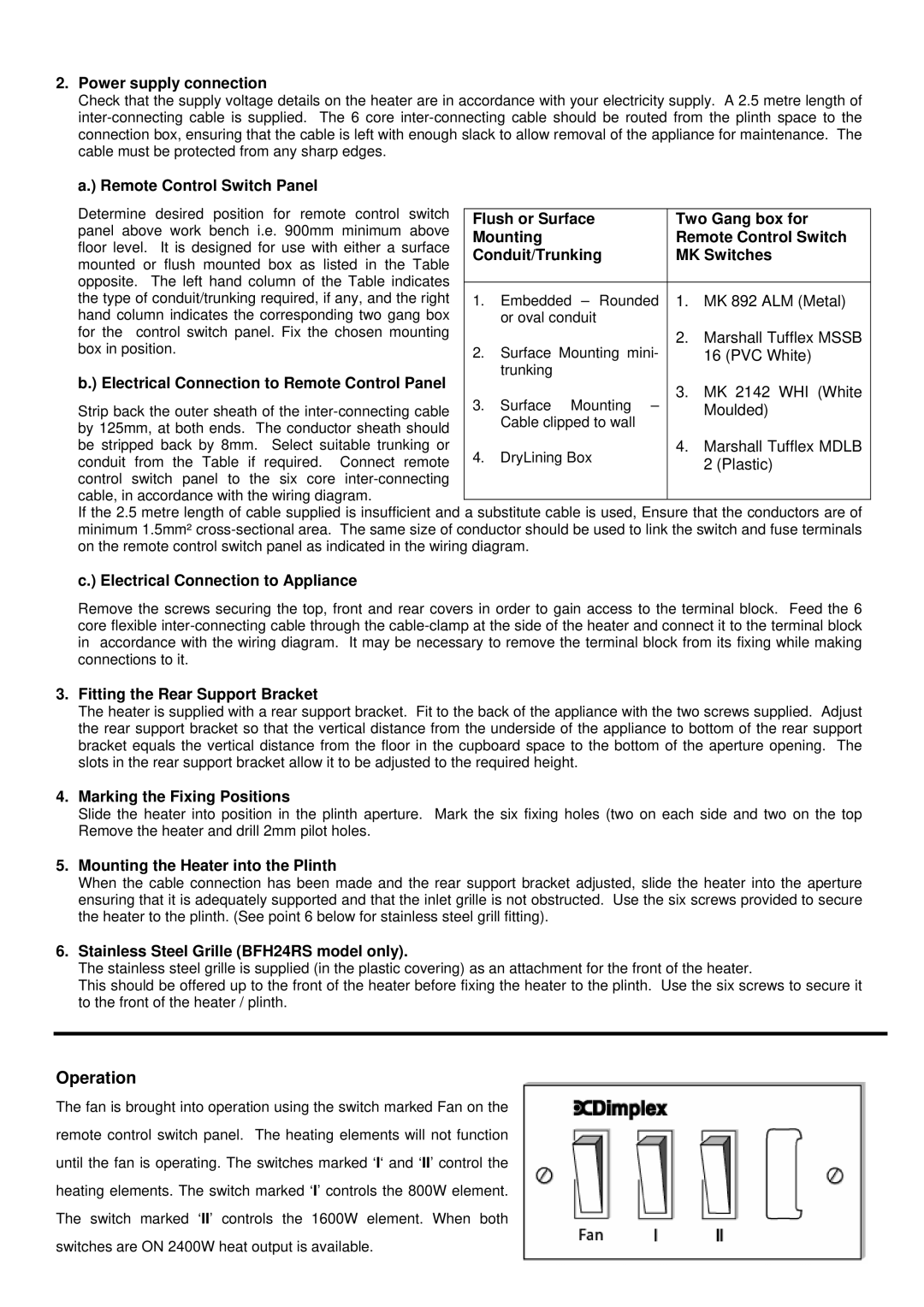

The fan is brought into operation using the switch marked Fan on the

remote control switch panel. The heating elements will not function

until the fan is operating. The switches marked ‘I‘ and ‘II’ control the

heating elements. The switch marked ‘I’ controls the 800W element.

The switch marked ‘II’ controls the 1600W element. When both

switches are ON 2400W heat output is available.