OPERATION AND USE

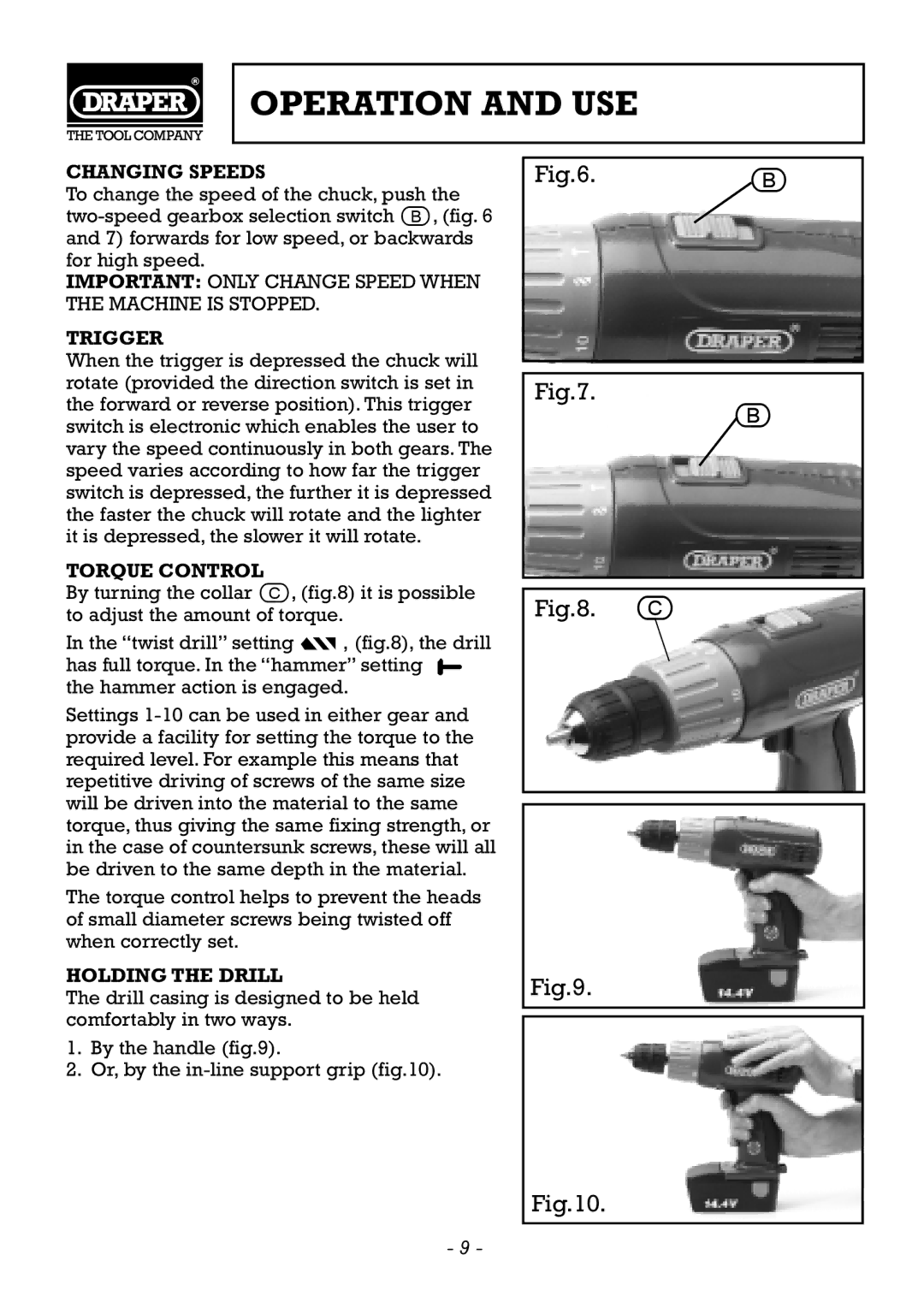

CHANGING SPEEDS

To change the speed of the chuck, push the

IMPORTANT: ONLY CHANGE SPEED WHEN THE MACHINE IS STOPPED.

TRIGGER

When the trigger is depressed the chuck will rotate (provided the direction switch is set in the forward or reverse position). This trigger switch is electronic which enables the user to vary the speed continuously in both gears. The speed varies according to how far the trigger switch is depressed, the further it is depressed the faster the chuck will rotate and the lighter it is depressed, the slower it will rotate.

TORQUE CONTROL

By turning the collar ✬✌, (fig.8) it is possible to adjust the amount of torque.

In the “twist drill” setting ![]() , (fig.8), the drill has full torque. In the “hammer” setting

, (fig.8), the drill has full torque. In the “hammer” setting ![]()

the hammer action is engaged.

Settings

The torque control helps to prevent the heads of small diameter screws being twisted off when correctly set.

HOLDING THE DRILL

The drill casing is designed to be held comfortably in two ways.

1.By the handle (fig.9).

2.Or, by the

Fig.6.✫✌

Fig.7.

✫✌

Fig.8. ✬✌

Fig.9.

Fig.10.

- 9 -