BEFORE USING THIS AIR TOOL

To ensure long life be sure to oil the tool daily. Pour 4 drops of Eagle air tool (SEA 20 non detergent) oil into the air inlet, and then run the tool for a few seconds to clean.

If tool is an impact wrench fitted with a “Zirc” grease fitting:

The hammer mechanism of this tool also needs to be greased from time to time (depending on usage). The tool is equipped with grease fitting for this purpose; use this connection to

PLEASE USE EAGLE SEA 20 NON DETERGENT OIL

OPERATING INSTRUCTIONS

Add oil throughout the day when using. We highly recommend use of an

Hold the tool away from work when starting. Set it down on the work evenly and make the cut. When cut is completed, lift tool away from work before stopping the motor. Use only discs rated at 20000 RPM or higher. Accessory retainers should be used to prevent ejec- tion of the accessory which might injure persons.

EXCEPTION: Retainers need not be used if in compliance with acceptable safety codes. In such cases, to avoid injury, the trigger should never be depressed unless the accessory is held firmly against the work piece. Accessory should be removed when tool is not in use.

TROUBLESHOOTING

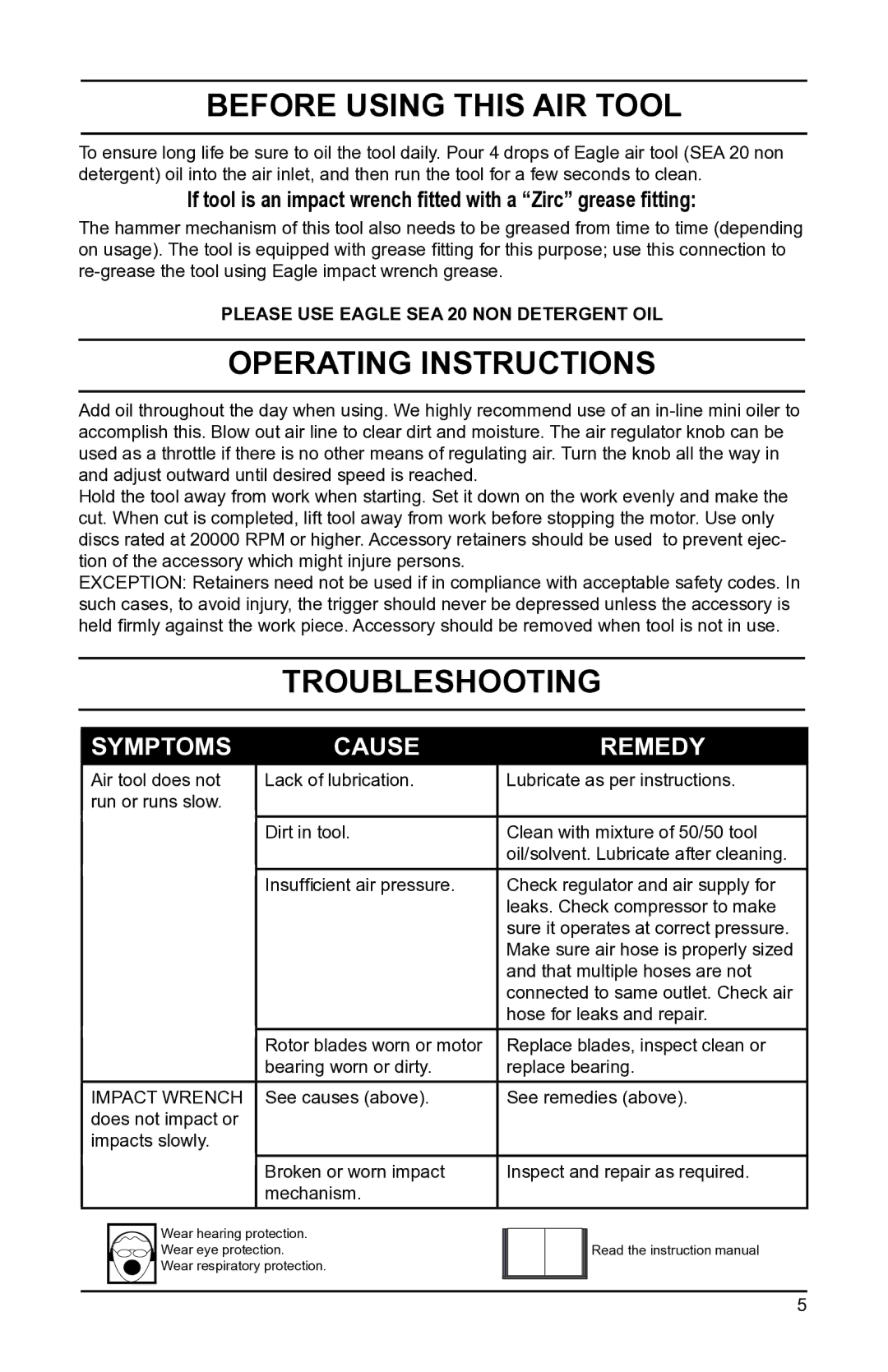

SYMPTOMS | CAUSE | REMEDY |

Air tool does not | Lack of lubrication. | Lubricate as per instructions. |

run or runs slow. |

|

|

|

|

|

| Dirt in tool. | Clean with mixture of 50/50 tool |

| ||

|

| oil/solvent. Lubricate after cleaning. |

|

|

|

| Insufficient air pressure. | Check regulator and air supply for |

| ||

|

| leaks. Check compressor to make |

|

| sure it operates at correct pressure. |

|

| Make sure air hose is properly sized |

|

| and that multiple hoses are not |

|

| connected to same outlet. Check air |

|

| hose for leaks and repair. |

|

|

|

| Rotor blades worn or motor | Replace blades, inspect clean or |

| ||

| bearing worn or dirty. | replace bearing. |

|

|

|

IMPACT WRENCH | See causes (above). | See remedies (above). |

does not impact or |

|

|

impacts slowly. |

|

|

| Broken or worn impact | Inspect and repair as required. |

| ||

| mechanism. |

|

Wear hearing protection. |

Wear eye protection. |

Wear respiratory protection. |

Read the instruction manual