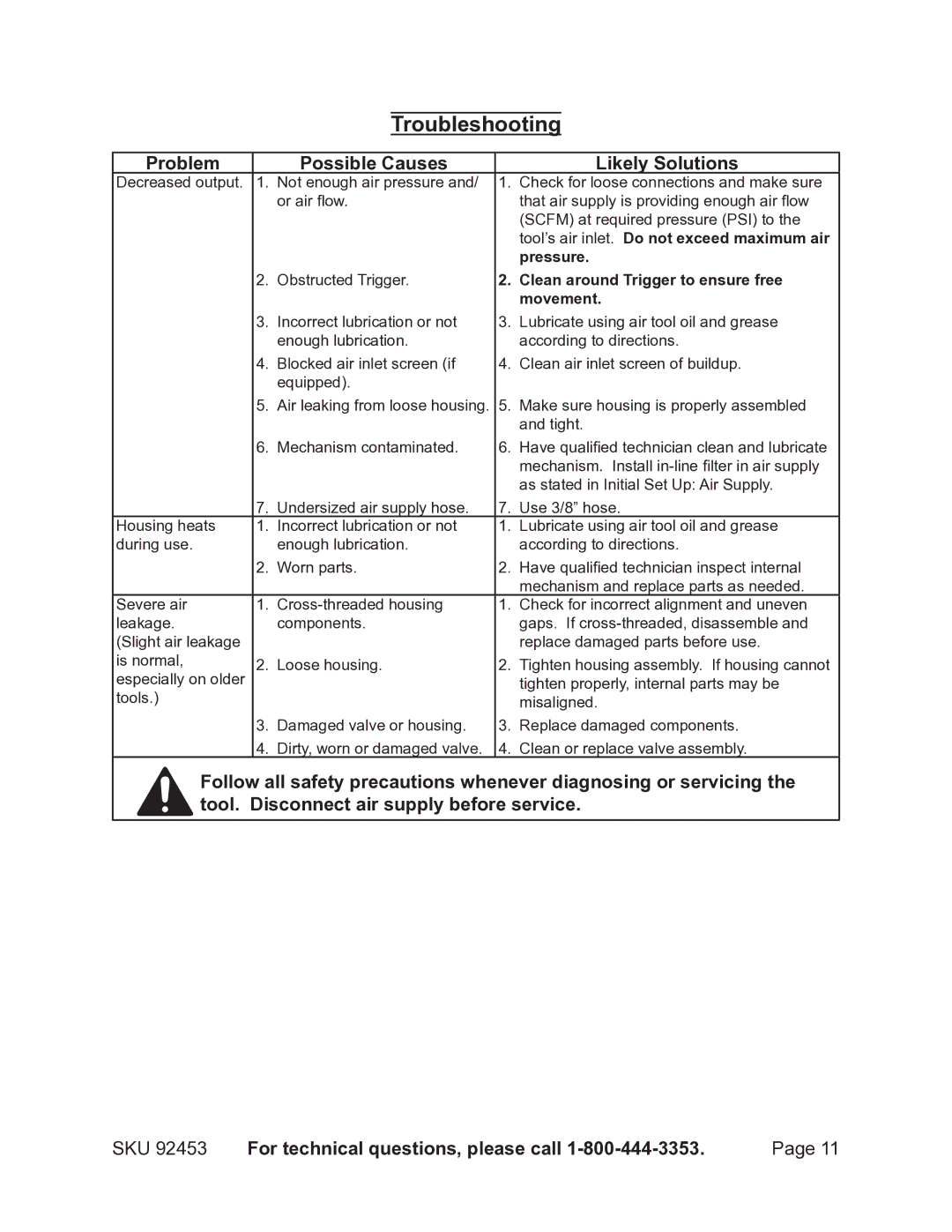

Troubleshooting

Problem | Possible Causes |

| Likely Solutions |

Decreased output. 1. Not enough air pressure and/ | 1. | Check for loose connections and make sure | |

| or air flow. |

| that air supply is providing enough air flow |

|

|

| (SCFM) at required pressure (PSI) to the |

|

|

| tool’s air inlet. Do not exceed maximum air |

|

|

| pressure. |

2. | Obstructed Trigger. | 2. | Clean around Trigger to ensure free |

|

|

| movement. |

3. | Incorrect lubrication or not | 3. | Lubricate using air tool oil and grease |

| enough lubrication. |

| according to directions. |

4. | Blocked air inlet screen (if | 4. | Clean air inlet screen of buildup. |

| equipped). |

|

|

5.Air leaking from loose housing. 5. Make sure housing is properly assembled and tight.

| 6. | Mechanism contaminated. | 6. | Have qualified technician clean and lubricate |

|

|

|

| mechanism. Install |

|

|

|

| as stated in Initial Set Up: Air Supply. |

| 7. | Undersized air supply hose. | 7. | Use 3/8” hose. |

Housing heats | 1. | Incorrect lubrication or not | 1. | Lubricate using air tool oil and grease |

during use. |

| enough lubrication. |

| according to directions. |

| 2. | Worn parts. | 2. | Have qualified technician inspect internal |

|

|

|

| mechanism and replace parts as needed. |

Severe air | 1. | 1. | Check for incorrect alignment and uneven | |

leakage. |

| components. |

| gaps. If |

(Slight air leakage |

|

|

| replace damaged parts before use. |

is normal, | 2. Loose housing. | 2. | Tighten housing assembly. If housing cannot | |

especially on older |

|

|

| tighten properly, internal parts may be |

tools.) |

|

|

| misaligned. |

| 3. | Damaged valve or housing. | 3. | Replace damaged components. |

| 4. | Dirty, worn or damaged valve. | 4. | Clean or replace valve assembly. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

SKU 92453 | For technical questions, please call | Page 11 |