STORING / MAINTAINING YOUR SPRAYER

•The sprayer should be stored out of direct sunlight in a cool dry space.

•Before freezing weather make sure to drain all liquid in the tank, pump, pressure cylinder, hose,

(See “Cleaning” section). Lock the

•When service is required call your nearest dealer and always insist on original manufactured replacement parts.

•Inspect the hose, wand, pump, tank and

•Every year prior to spraying remove felt gasket (see Pump Disassembly and Rebuild) and saturate with a light oil. Oil periodically thru out the season as needed.

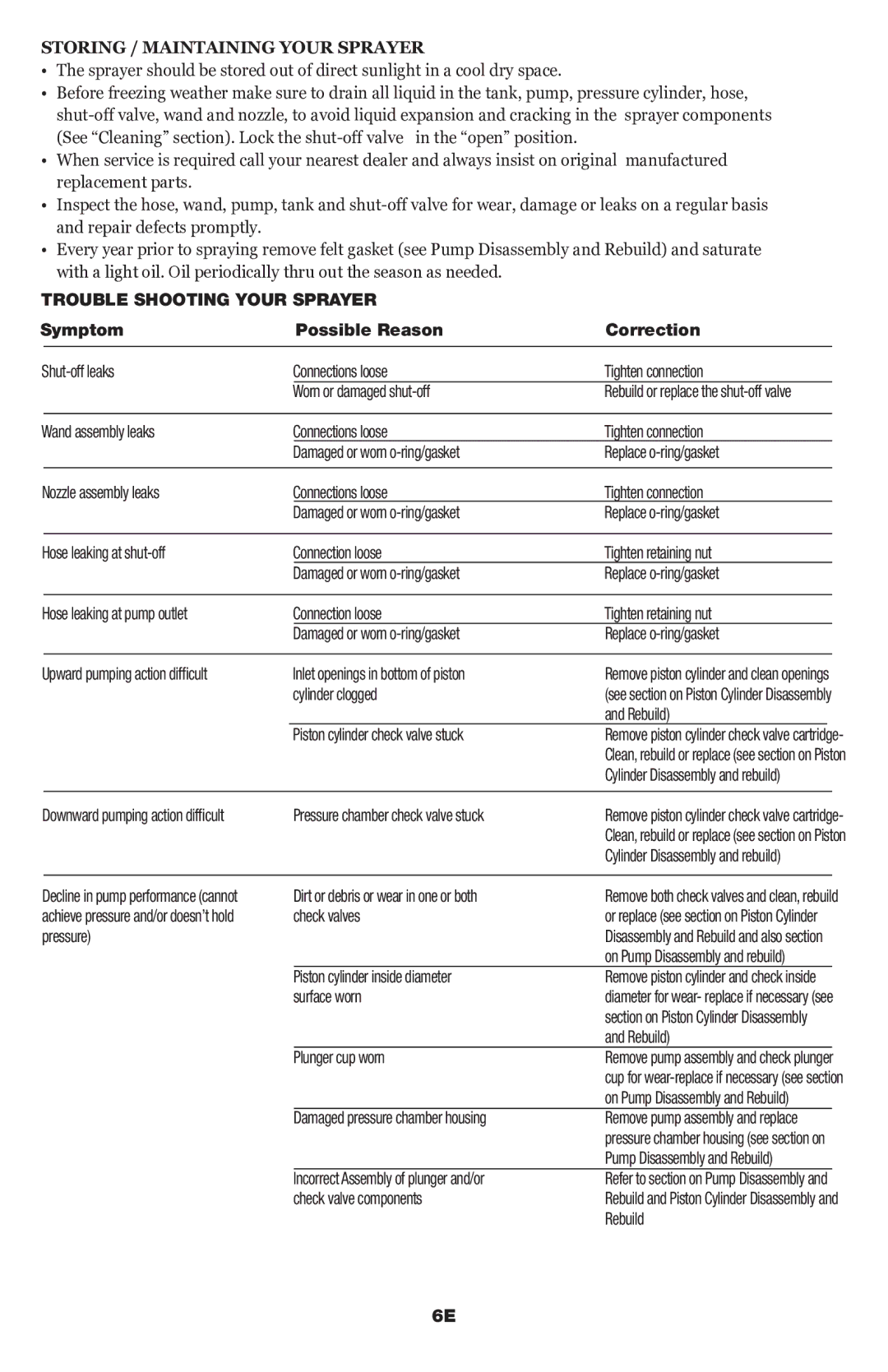

TROUBLE SHOOTING YOUR SPRAYER

Symptom |

| Possible Reason | Correction | ||||

|

|

|

|

|

|

| |

Connections loose | Tighten connection | ||||||

|

|

| Worn or damaged | Rebuild or replace the |

| ||

|

|

|

|

|

|

|

|

Wand assembly leaks | Connections loose | Tighten connection |

| ||||

|

|

| Damaged or worn | Replace | |||

|

|

|

|

|

|

|

|

Nozzle assembly leaks | Connections loose | Tighten connection |

| ||||

|

|

| Damaged or worn | Replace | |||

|

|

|

|

|

|

|

|

Hose leaking at | Connection loose | Tighten retaining nut | |||||

|

|

| Damaged or worn | Replace |

| ||

|

|

|

|

|

|

|

|

Hose leaking at pump outlet | Connection loose | Tighten retaining nut | |||||

|

|

| Damaged or worn | Replace |

| ||

|

|

|

|

|

|

|

|

Upward pumping action difficult | Inlet openings in bottom of piston | Remove piston cylinder and clean openings | |||||

|

|

| cylinder clogged | (see section on Piston Cylinder Disassembly | |||

|

|

|

|

| and Rebuild) |

| |

|

|

| Piston cylinder check valve stuck | Remove piston cylinder check valve cartridge- | |||

|

|

|

|

| Clean, rebuild or replace (see section on Piston | ||

|

|

|

|

| Cylinder Disassembly and rebuild) | ||

|

|

|

|

|

|

|

|

Downward pumping action difficult | Pressure chamber check valve stuck | Remove piston cylinder check valve cartridge- | |||||

|

|

|

|

| Clean, rebuild or replace (see section on Piston | ||

|

|

|

|

| Cylinder Disassembly and rebuild) | ||

|

|

|

|

|

|

|

|

Decline in pump performance (cannot | Dirt or debris or wear in one or both | Remove both check valves and clean, rebuild | |||||

achieve pressure and/or doesn’t hold | check valves | or replace (see section on Piston Cylinder | |||||

pressure) |

|

| Disassembly and Rebuild and also section | ||||

|

|

|

|

| on Pump Disassembly and rebuild) | ||

|

|

|

| Piston cylinder inside diameter | Remove piston cylinder and check inside |

| |

|

|

| surface worn | diameter for wear- replace if necessary (see | |||

|

|

|

|

| section on Piston Cylinder Disassembly | ||

|

|

|

|

| and Rebuild) | ||

|

|

|

| Plunger cup worn | Remove pump assembly and check plunger |

| |

|

|

|

|

| cup for | ||

|

|

|

|

| on Pump Disassembly and Rebuild) | ||

|

|

|

| Damaged pressure chamber housing | Remove pump assembly and replace |

| |

|

|

|

|

| pressure chamber housing (see section on | ||

|

|

|

|

| Pump Disassembly and Rebuild) | ||

|

|

|

| Incorrect Assembly of plunger and/or | Refer to section on Pump Disassembly and |

| |

|

|

| check valve components | Rebuild and Piston Cylinder Disassembly and | |||

|

|

|

|

| Rebuild | ||

6E