Figure 4

Piston Cylinder

Figure 5

Check Valve

Figure 6

Flat side

Seal Ball

Counterbore Side

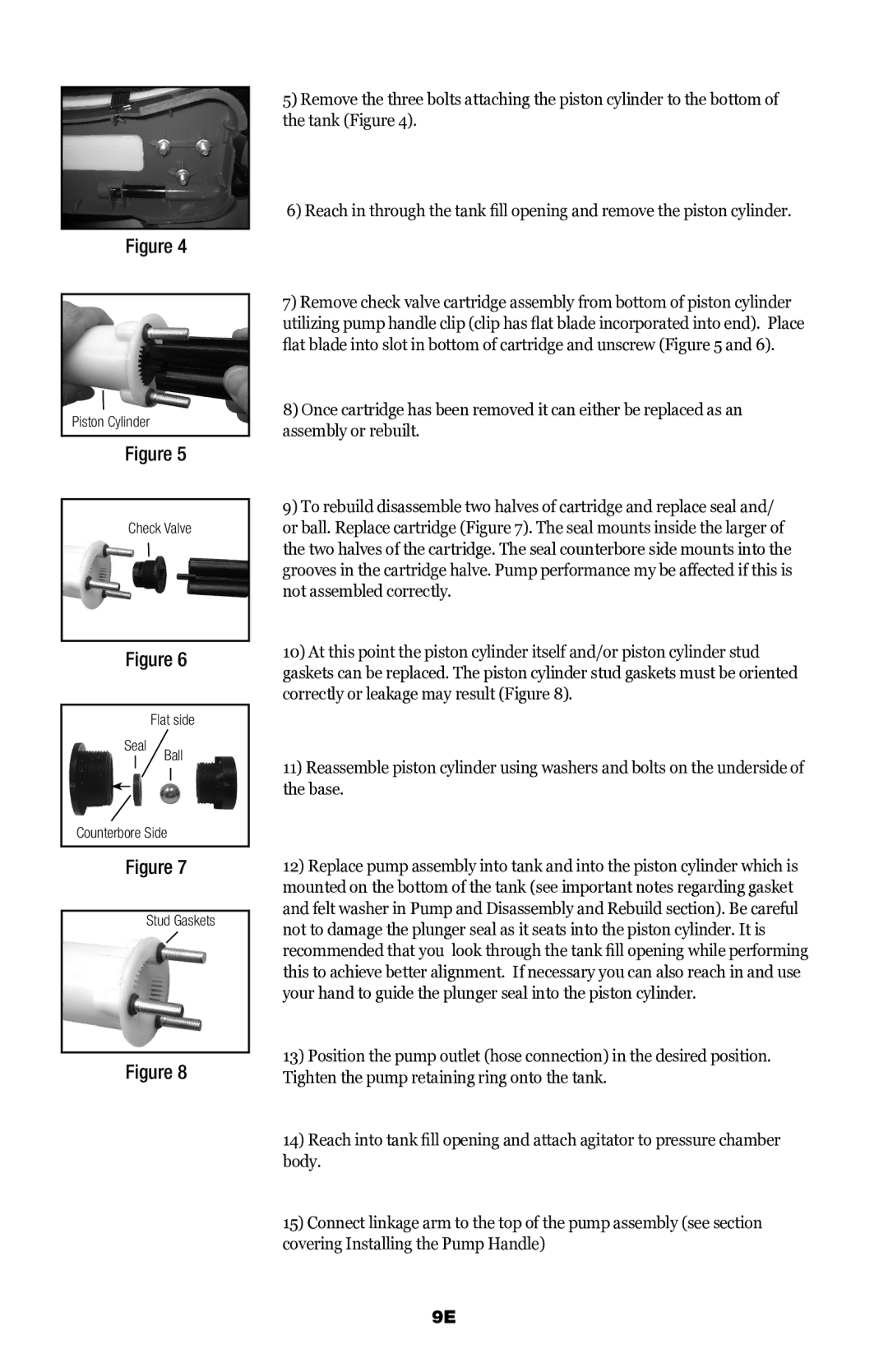

Figure 7

Stud Gaskets

Figure 8

5)Remove the three bolts attaching the piston cylinder to the bottom of the tank (Figure 4).

6)Reach in through the tank fll opening and remove the piston cylinder.

7)Remove check valve cartridge assembly from bottom of piston cylinder utilizing pump handle clip (clip has fat blade incorporated into end). Place fat blade into slot in bottom of cartridge and unscrew (Figure 5 and 6).

8)Once cartridge has been removed it can either be replaced as an assembly or rebuilt.

9)To rebuild disassemble two halves of cartridge and replace seal and/

or ball. Replace cartridge (Figure 7). The seal mounts inside the larger of the two halves of the cartridge. The seal counterbore side mounts into the grooves in the cartridge halve. Pump performance my be affected if this is not assembled correctly.

10)At this point the piston cylinder itself and/or piston cylinder stud gaskets can be replaced. The piston cylinder stud gaskets must be oriented correctly or leakage may result (Figure 8).

11)Reassemble piston cylinder using washers and bolts on the underside of the base.

12)Replace pump assembly into tank and into the piston cylinder which is mounted on the bottom of the tank (see important notes regarding gasket and felt washer in Pump and Disassembly and Rebuild section). Be careful not to damage the plunger seal as it seats into the piston cylinder. It is recommended that you look through the tank fll opening while performing this to achieve better alignment. If necessary you can also reach in and use your hand to guide the plunger seal into the piston cylinder.

13)Position the pump outlet (hose connection) in the desired position.

Tighten the pump retaining ring onto the tank.

14)Reach into tank fll opening and attach agitator to pressure chamber body.

15)Connect linkage arm to the top of the pump assembly (see section covering Installing the Pump Handle)

9E