CONNECTING TO GAS SUPPLY

This appliance is designed to be installed with an appliance flexible connection only. Supply piping should not be less than R3/8. Connection is made to the Rc ½ (½” B.S.P.) female threaded entry pipe located just below the hotplate level on the rear left hand side of the appliance. NOTE: ONLY LIQUID

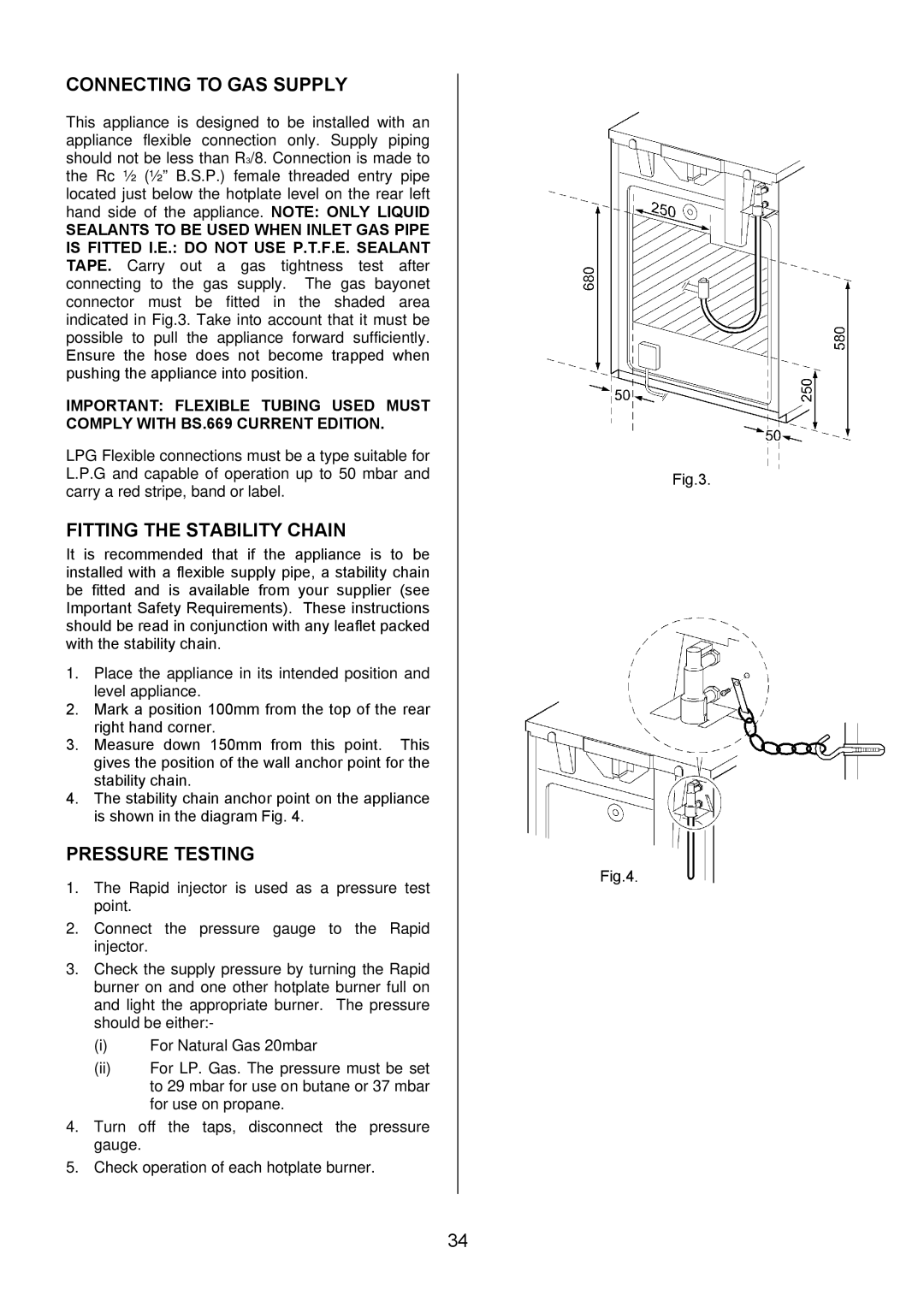

SEALANTS TO BE USED WHEN INLET GAS PIPE IS FITTED I.E.: DO NOT USE P.T.F.E. SEALANT TAPE. Carry out a gas tightness test after connecting to the gas supply. The gas bayonet connector must be fitted in the shaded area indicated in Fig.3. Take into account that it must be possible to pull the appliance forward sufficiently.

Ensure the hose does not become trapped when pushing the appliance into position.

IMPORTANT: FLEXIBLE TUBING USED MUST COMPLY WITH BS.669 CURRENT EDITION.

LPG Flexible connections must be a type suitable for L.P.G and capable of operation up to 50 mbar and carry a red stripe, band or label.

FITTING THE STABILITY CHAIN

It is recommended that if the appliance is to be installed with a flexible supply pipe, a stability chain be fitted and is available from your supplier (see Important Safety Requirements). These instructions should be read in conjunction with any leaflet packed with the stability chain.

1.Place the appliance in its intended position and level appliance.

2.Mark a position 100mm from the top of the rear right hand corner.

3.Measure down 150mm from this point. This gives the position of the wall anchor point for the stability chain.

4.The stability chain anchor point on the appliance is shown in the diagram Fig. 4.

PRESSURE TESTING

1.The Rapid injector is used as a pressure test point.

2.Connect the pressure gauge to the Rapid injector.

3.Check the supply pressure by turning the Rapid burner on and one other hotplate burner full on and light the appropriate burner. The pressure should be either:-

(i)For Natural Gas 20mbar

(ii)For LP. Gas. The pressure must be set to 29 mbar for use on butane or 37 mbar for use on propane.

4.Turn off the taps, disconnect the pressure gauge.

5.Check operation of each hotplate burner.

Fig.3.

Fig.4.

34