Electrolux Dishwashing Rack Type WTM250

EASY TO CLEAN AND MAINTAIN

•The

•WTM250 has smooth surfaces. 304 AISI stainless steel front and side panels, strainers and wash and rinse arms.

•Wash arms and double tank filter (flat and deep box) easy to remove.

•Height adjustable stainless steel feet.

•All models finished in top quality materials with double skinned construction to aid durability and reduce noise.

•

•Hinged flap for easy access to

the energy saving condenser unit.

•Large balanced inspection doors for easy access to wash area.

•

EASY TO USE

•Automatic start/stop function.

•Advanced electric control panel with sound signals and visual display.

•Counter balanced door with safety switch and easy to grip handle.

•

•Electronic control panel with autodiagnostic check control.

EASY ON THE ENVIRONMENT

•35mm thickness foam injection insulated doors to reduce noise and reduce heat dispersion.

•Available with version equipped with Energy Saving Device (ESD) to

•Separate

•98% recyclable by weight.

•CFC free packaging.

•Low noise level <70dBA.

•Developed and produced in ISO 9001 and ISO 14001 certified factory.

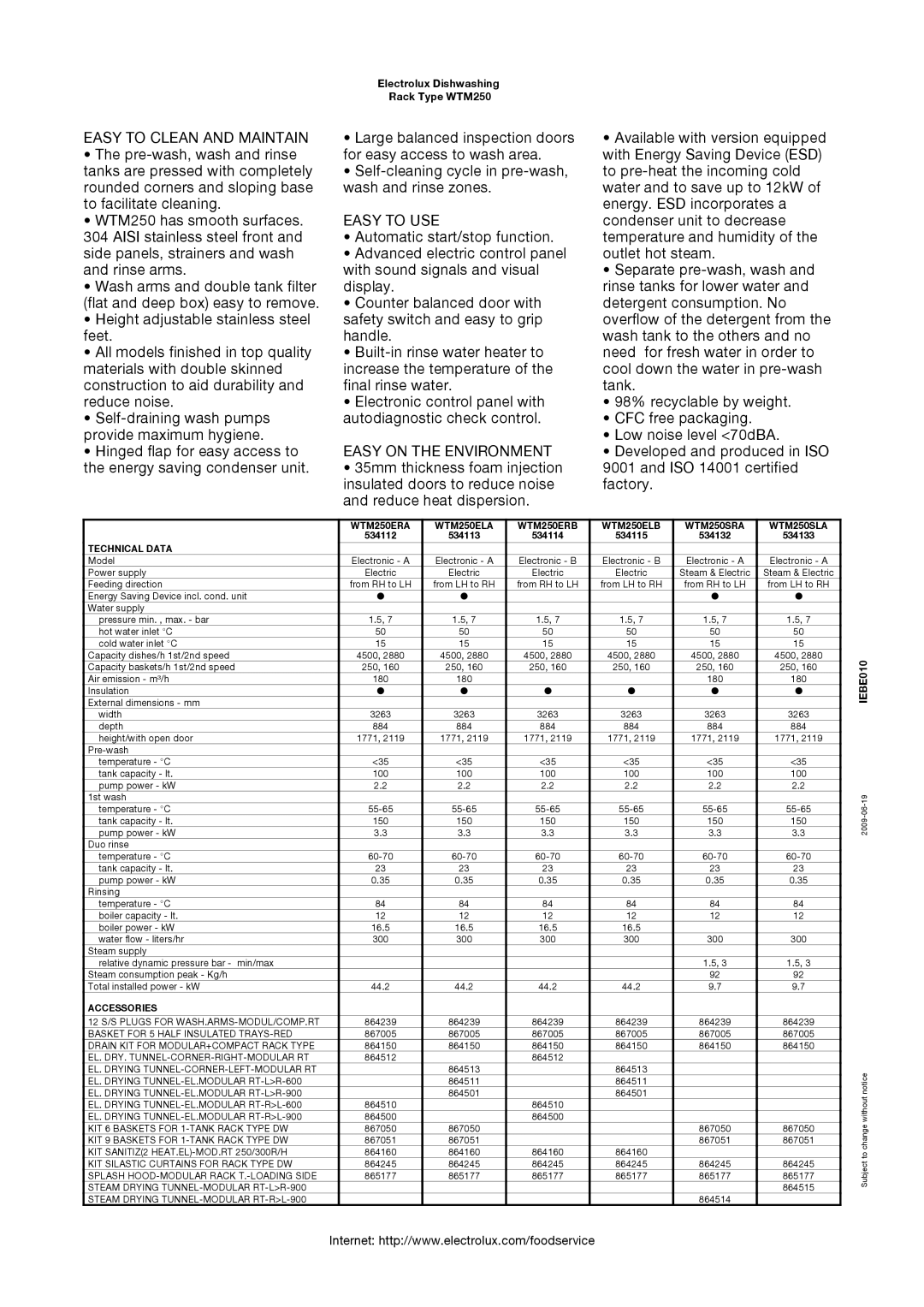

| WTM250ERA | WTM250ELA | WTM250ERB | WTM250ELB | WTM250SRA | WTM250SLA |

| |

| 534112 | 534113 | 534114 | 534115 | 534132 | 534133 |

| |

TECHNICAL DATA |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| ||

Model | Electronic - A | Electronic - A | Electronic - B | Electronic - B | Electronic - A | Electronic - A |

| |

Power supply | Electric | Electric | Electric | Electric | Steam & Electric | Steam & Electric |

| |

Feeding direction | from RH to LH | from LH to RH | from RH to LH | from LH to RH | from RH to LH | from LH to RH |

| |

Energy Saving Device incl. cond. unit | ● | ● |

|

| ● | ● |

| |

Water supply |

|

|

|

|

|

|

| |

pressure min. , max. - bar | 1.5, 7 | 1.5, 7 | 1.5, 7 | 1.5, 7 | 1.5, 7 | 1.5, 7 |

| |

hot water inlet °C | 50 | 50 | 50 | 50 | 50 | 50 |

| |

cold water inlet °C | 15 | 15 | 15 | 15 | 15 | 15 |

| |

Capacity dishes/h 1st/2nd speed | 4500, 2880 | 4500, 2880 | 4500, 2880 | 4500, 2880 | 4500, 2880 | 4500, 2880 | IEBE010 | |

Capacity baskets/h 1st/2nd speed | 250, 160 | 250, 160 | 250, 160 | 250, 160 | 250, 160 | 250, 160 | ||

Air emission - m³/h | 180 | 180 |

|

| 180 | 180 |

| |

Insulation | ● | ● | ● | ● | ● | ● |

| |

External dimensions - mm |

|

|

|

|

|

|

| |

width | 3263 | 3263 | 3263 | 3263 | 3263 | 3263 |

| |

depth | 884 | 884 | 884 | 884 | 884 | 884 |

| |

height/with open door | 1771, 2119 | 1771, 2119 | 1771, 2119 | 1771, 2119 | 1771, 2119 | 1771, 2119 |

| |

|

|

|

|

|

|

| ||

temperature - °C | <35 | <35 | <35 | <35 | <35 | <35 |

| |

tank capacity - lt. | 100 | 100 | 100 | 100 | 100 | 100 |

| |

pump power - kW | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| |

1st wash |

|

|

|

|

|

| 19 | |

temperature - °C | 06- | |||||||

tank capacity - lt. | 150 | 150 | 150 | 150 | 150 | 150 | - | |

2009 | ||||||||

pump power - kW | 3.3 | 3.3 | 3.3 | 3.3 | 3.3 | 3.3 | ||

| ||||||||

Duo rinse |

|

|

|

|

|

|

| |

temperature - °C |

| |||||||

tank capacity - lt. | 23 | 23 | 23 | 23 | 23 | 23 |

| |

pump power - kW | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 |

| |

Rinsing |

|

|

|

|

|

|

| |

temperature - °C | 84 | 84 | 84 | 84 | 84 | 84 |

| |

boiler capacity - lt. | 12 | 12 | 12 | 12 | 12 | 12 |

| |

boiler power - kW | 16.5 | 16.5 | 16.5 | 16.5 |

|

|

| |

water flow - liters/hr | 300 | 300 | 300 | 300 | 300 | 300 |

| |

Steam supply |

|

|

|

|

|

|

| |

relative dynamic pressure bar - min/max |

|

|

|

| 1.5, 3 | 1.5, 3 |

| |

Steam consumption peak - Kg/h |

|

|

|

| 92 | 92 |

| |

Total installed power - kW | 44.2 | 44.2 | 44.2 | 44.2 | 9.7 | 9.7 |

| |

ACCESSORIES |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

12 S/S PLUGS FOR | 864239 | 864239 | 864239 | 864239 | 864239 | 864239 |

| |

BASKET FOR 5 HALF INSULATED | 867005 | 867005 | 867005 | 867005 | 867005 | 867005 |

| |

DRAIN KIT FOR MODULAR+COMPACT RACK TYPE | 864150 | 864150 | 864150 | 864150 | 864150 | 864150 |

| |

EL. DRY. | 864512 |

| 864512 |

|

|

|

| |

EL. DRYING |

| 864513 |

| 864513 |

|

| notice | |

EL. DRYING |

| 864511 |

| 864511 |

|

| ||

|

|

|

|

| ||||

EL. DRYING |

| 864501 |

| 864501 |

|

| without | |

EL. DRYING | 864500 |

| 864500 |

|

|

| ||

EL. DRYING | 864510 |

| 864510 |

|

|

|

| |

|

|

|

|

|

|

| to change | |

KIT 6 BASKETS FOR | 867050 | 867050 |

|

| 867050 | 867050 | ||

KIT 9 BASKETS FOR | 867051 | 867051 |

|

| 867051 | 867051 | ||

KIT SANITIZ(2 | 864160 | 864160 | 864160 | 864160 |

|

| ||

KIT SILASTIC CURTAINS FOR RACK TYPE DW | 864245 | 864245 | 864245 | 864245 | 864245 | 864245 | Subject | |

SPLASH | 865177 | 865177 | 865177 | 865177 | 865177 | 865177 | ||

| ||||||||

STEAM DRYING |

|

|

|

|

| 864515 |

| |

STEAM DRYING |

|

|

|

| 864514 |

|

|

Internet: http://www.electrolux.com/foodservice