ENGLISH

ENGLISH

−adding approx.

1.Put socket on the drive.

2.Set direction of rotation with the reversing knob:

−reversing knob set to the left: forward/driving

−Reversing knob set to the right: R = reverse/loosening

3.Adjust working pressure at the com- pressor (see Technical Specificati- ons for max. permissible working pressure).

4.Connect quick coupler to the air supply.

5.Pull trigger to start.

5. Care and Maintenance

ADanger!

Always disconnect from air supply before servicing.

Repair and maintenance work other than described in this section must

be carried out by qualified specialists only .

•Check all screwed connections for tightness, tighten if necessary.

•When the tool is not lubricated by a service unit or line oiler, manually add 3 - 5 drops of pneumatic oil for every 15 minutes of operation (con- tinuous operation) into the air inlet.

•Never store the tool outdoors, in unprotected areas or in damp locati- ons.

6. Available Accessories

•Pneumatic oil 0.5 litre

Special lubricant for air tools, ser- vice units and line oilers.

•Line oiler R1/4" female

For fitting directly to air tools. Oil level can always be checked through sight glass.

•

For fitting directly to air tools. Impro- ves tool manoeuverability.

•Socket set 1/2" consisting of 10 sockets

(10, 11, 12, 13, 15, 17, 19, 21, 22, 24 mm).

7. Repairs

ADanger!

Repairs to air tools must be carried out by qualified specialists ONLY!

Air tools in need of repair can be send to the service centre in your country. See Spare Parts List for address.

Please attach a description of the fault to the air tool.

8. Environmental Protection

The tool's packaging materials are 100 % recyclable.

Worn out machines and accessories contain considerable amounts of valu- able raw and plastic materials, which can be recycled.

These instructions are printed on paper produced with elemental chlorine free bleaching process.

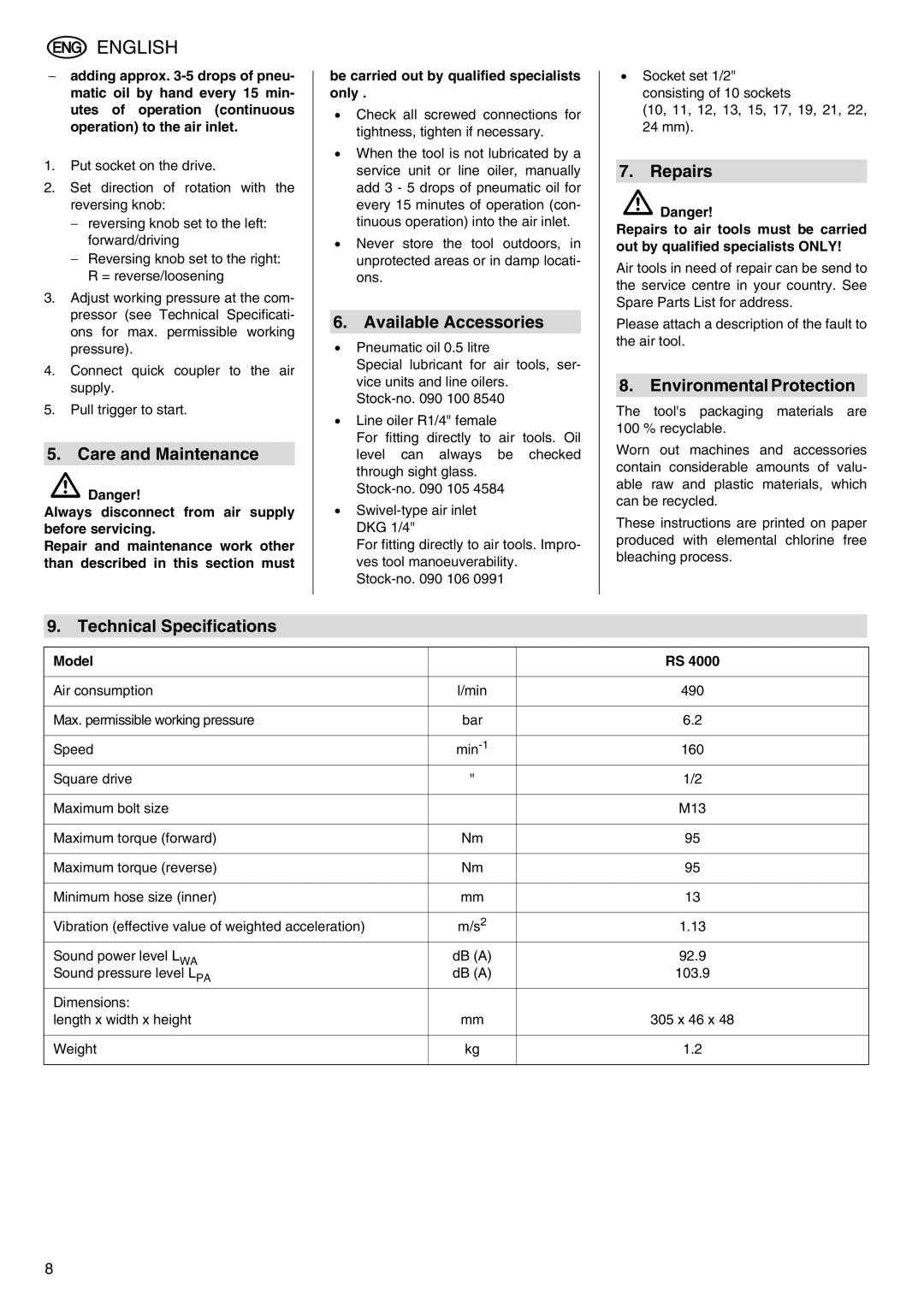

9. Technical Specifications

Model |

| RS 4000 |

|

|

|

Air consumption | l/min | 490 |

|

|

|

Max. permissible working pressure | bar | 6.2 |

|

|

|

Speed | 160 | |

Square drive | " | 1/2 |

|

|

|

Maximum bolt size |

| M13 |

|

|

|

Maximum torque (forward) | Nm | 95 |

|

|

|

Maximum torque (reverse) | Nm | 95 |

|

|

|

Minimum hose size (inner) | mm | 13 |

|

|

|

Vibration (effective value of weighted acceleration) | m/s2 | 1.13 |

Sound power level LWA | dB (A) | 92.9 |

Sound pressure level LPA | dB (A) | 103.9 |

Dimensions: |

|

|

length x width x height | mm | 305 x 46 x 48 |

|

|

|

Weight | kg | 1.2 |

|

|

|

8