MODEL 140,141, and 142 sensors | INSTALLATION |

INSTALLATION

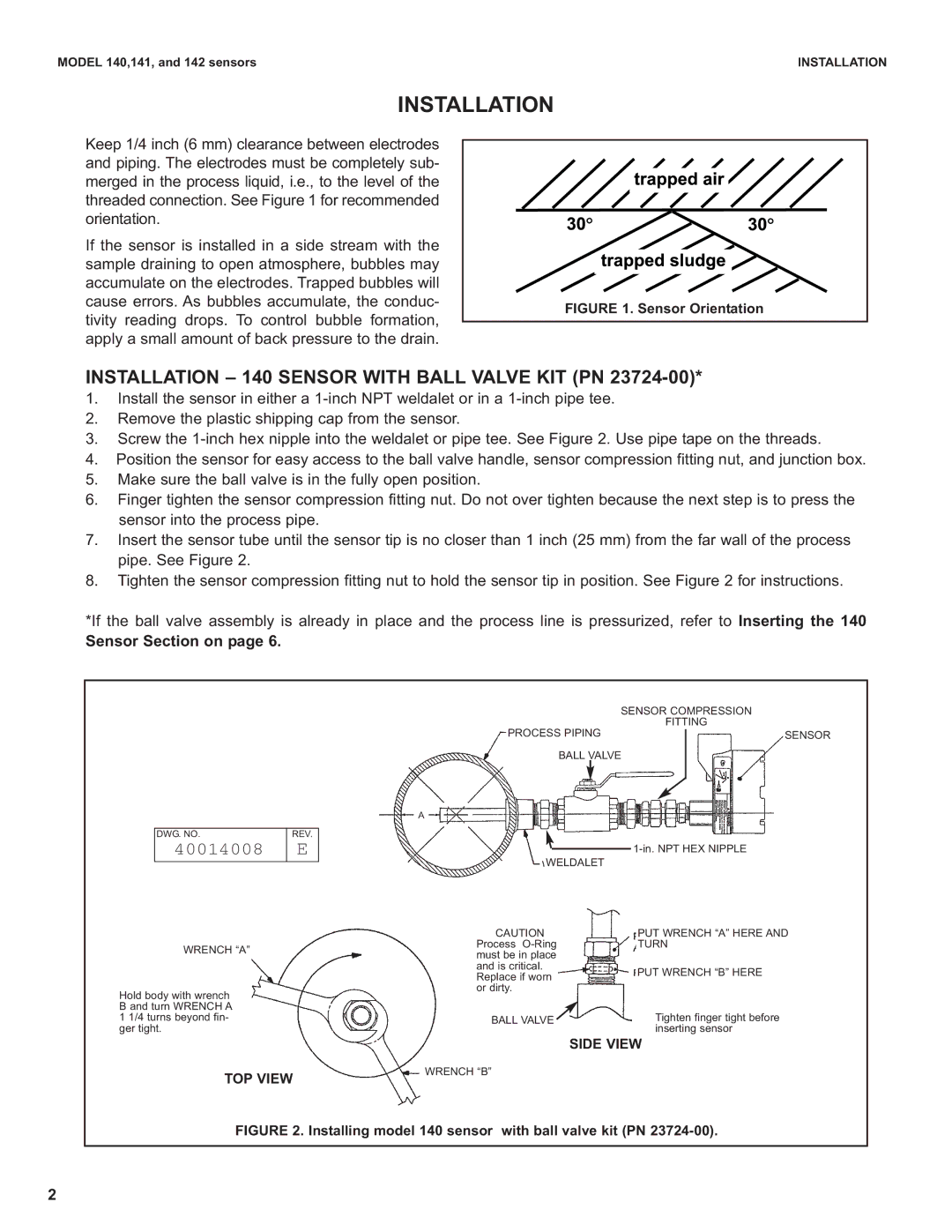

Keep 1/4 inch (6 mm) clearance between electrodes and piping. The electrodes must be completely sub- merged in the process liquid, i.e., to the level of the threaded connection. See Figure 1 for recommended orientation.

If the sensor is installed in a side stream with the sample draining to open atmosphere, bubbles may accumulate on the electrodes. Trapped bubbles will cause errors. As bubbles accumulate, the conduc- tivity reading drops. To control bubble formation, apply a small amount of back pressure to the drain.

° | ° |

FIGURE 1. Sensor Orientation |

|

INSTALLATION – 140 SENSOR WITH BALL VALVE KIT (PN 23724-00)*

1.Install the sensor in either a

2.Remove the plastic shipping cap from the sensor.

3.Screw the

4.Position the sensor for easy access to the ball valve handle, sensor compression fitting nut, and junction box.

5.Make sure the ball valve is in the fully open position.

6.Finger tighten the sensor compression fitting nut. Do not over tighten because the next step is to press the sensor into the process pipe.

7.Insert the sensor tube until the sensor tip is no closer than 1 inch (25 mm) from the far wall of the process pipe. See Figure 2.

8.Tighten the sensor compression fitting nut to hold the sensor tip in position. See Figure 2 for instructions.

*If the ball valve assembly is already in place and the process line is pressurized, refer to Inserting the 140

Sensor Section on page 6.

SENSOR COMPRESSION

FITTING

PROCESS PIPING

BALL VALVE

SENSOR

A

DWG. NO. | REV. |

40014008 | E |

|

|

WRENCH “A”

Hold body with wrench B and turn WRENCH A 1 1/4 turns beyond fin- ger tight.

![]()

WELDALET

| CAUTION | PUT WRENCH “A” HERE AND | |||

Process | TURN | ||||

must be in place |

|

| |||

and is critical. |

|

|

| ||

| PUT WRENCH “B” HERE |

| |||

Replace if worn |

|

| |||

|

|

| |||

or dirty. |

|

|

| ||

|

|

|

| Tighten finger tight before | |

| BALL VALVE |

|

| ||

|

| inserting sensor | |||

|

|

|

| ||

|

|

|

| ||

TOP VIEW

SIDE VIEW

WRENCH “B”

FIGURE 2. Installing model 140 sensor with ball valve kit (PN 23724-00).

2