MODEL 399VP pH/ORP SENSOR | SECTION 6.0 |

| TROUBLESHOOTING |

SECTION 6.0.

TROUBLESHOOTING

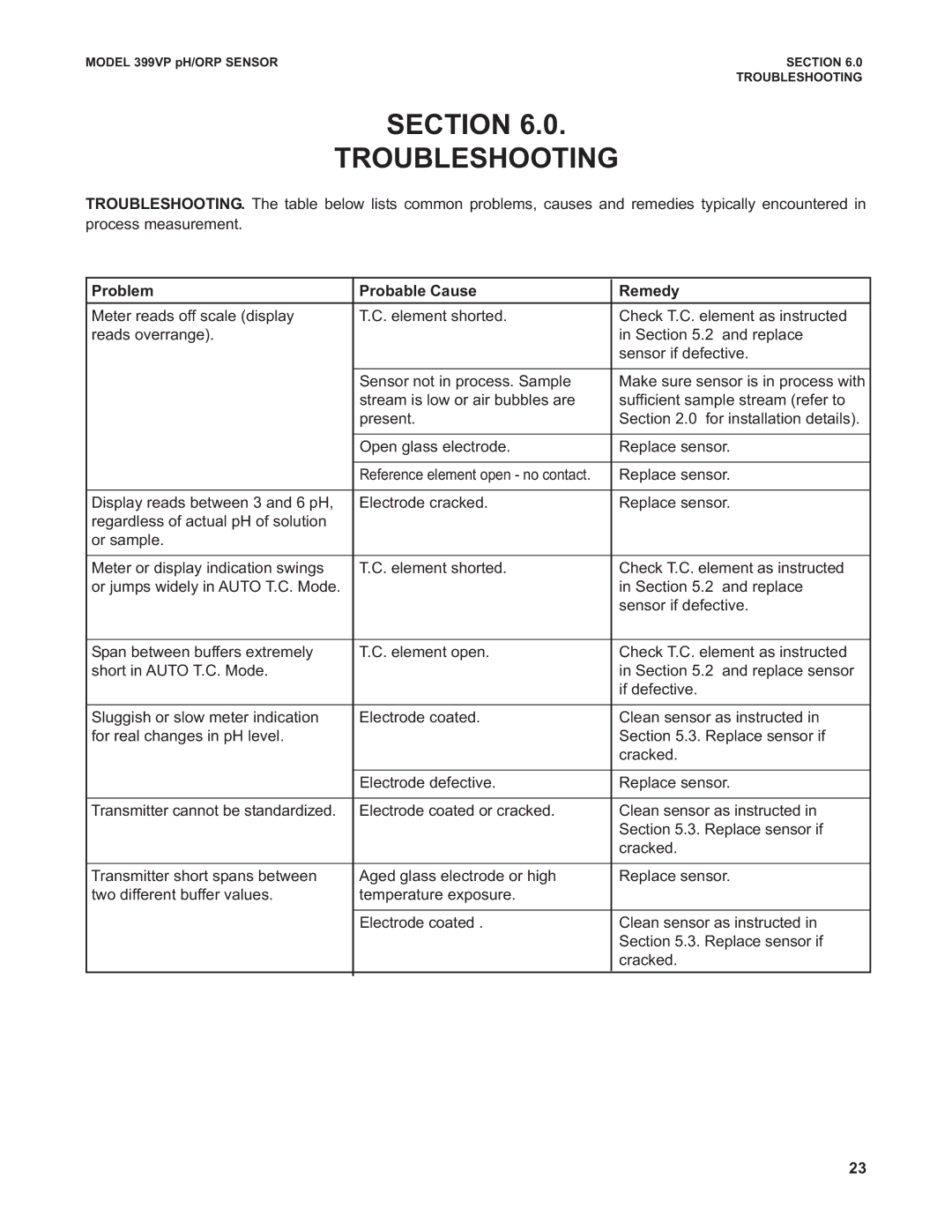

TROUBLESHOOTING. The table below lists common problems, causes and remedies typically encountered in process measurement.

Problem | Probable Cause |

| Remedy |

| |||

|

|

|

|

Meter reads off scale (display | T.C. element shorted. |

| Check T.C. element as instructed |

reads overrange). |

|

| in Section 5.2 and replace |

|

|

| sensor if defective. |

|

|

|

|

| Sensor not in process. Sample |

| Make sure sensor is in process with |

| stream is low or air bubbles are |

| sufficient sample stream (refer to |

| present. |

| Section 2.0 for installation details). |

|

|

|

|

| Open glass electrode. |

| Replace sensor. |

|

|

|

|

| Reference element open - no contact. |

| Replace sensor. |

|

|

|

|

Display reads between 3 and 6 pH, | Electrode cracked. |

| Replace sensor. |

regardless of actual pH of solution |

|

|

|

or sample. |

|

|

|

|

|

|

|

Meter or display indication swings | T.C. element shorted. |

| Check T.C. element as instructed |

or jumps widely in AUTO T.C. Mode. |

|

| in Section 5.2 and replace |

|

|

| sensor if defective. |

|

|

|

|

Span between buffers extremely | T.C. element open. |

| Check T.C. element as instructed |

short in AUTO T.C. Mode. |

|

| in Section 5.2 and replace sensor |

|

|

| if defective. |

|

|

|

|

Sluggish or slow meter indication | Electrode coated. |

| Clean sensor as instructed in |

for real changes in pH level. |

|

| Section 5.3. Replace sensor if |

|

|

| cracked. |

|

|

|

|

| Electrode defective. |

| Replace sensor. |

|

|

|

|

Transmitter cannot be standardized. | Electrode coated or cracked. |

| Clean sensor as instructed in |

|

|

| Section 5.3. Replace sensor if |

|

|

| cracked. |

|

|

|

|

Transmitter short spans between | Aged glass electrode or high |

| Replace sensor. |

two different buffer values. | temperature exposure. |

|

|

|

|

|

|

| Electrode coated . |

| Clean sensor as instructed in |

|

|

| Section 5.3. Replace sensor if |

|

|

| cracked. |

|

|

|

|

|

|

|

|

23