11. Adjust the tension screw until the proper belt tension is recorded by the Browning Belt Tension Checker. The recommended deflection force is 150 percent of the Edge value or the value given for a new belt in form 5453 included with the Browning Belt Tension Checker

WARNING! The surface on which the Motor Base is mounted must be flat. A base that is distorted or warped will not function properly. If the surface is not flat, correct the condition with shims.

Maintenance

Lubrication

The carriage tubes are provided with holes or fitting for lubrication. Every six months or as dictated by the application, wipe down the carriage rails and tension rod with an oily rag and apply a light grade grease. Be sure to remove all foreign material from the tubes and tension rod.

Changing Belts

Turn the tension rod counter clockwise to move the carriage enough to allow the old belt to be removed. Repeat steps 7 through 11 of the installation instructions to install the new belt.

Adjusting Belts

Periodic adjustment should not be needed. However, if it is suspected that the belt tension is not correct, then complete steps 10 and 11 of the installation instructions.

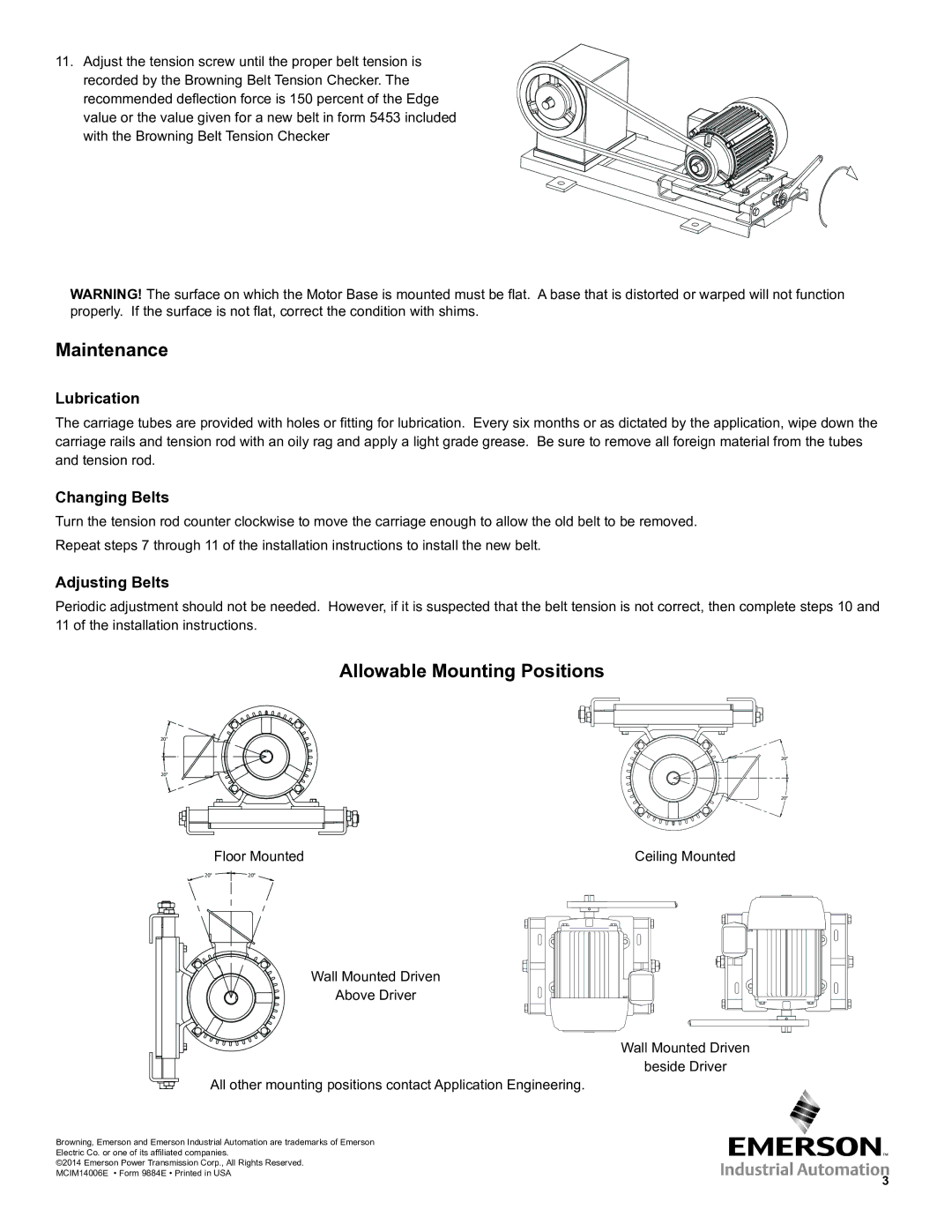

Allowable Mounting Positions

20°

20°

20°

20°

| Floor Mounted | Ceiling Mounted |

20° | 20° |

|

Wall Mounted Driven

Above Driver

Wall Mounted Driven beside Driver

All other mounting positions contact Application Engineering.

Browning, Emerson and Emerson Industrial Automation are trademarks of Emerson |

|

Electric Co. or one of its affiliated companies. |

|

©2014 Emerson Power Transmission Corp., All Rights Reserved. |

|

MCIM14006E • Form 9884E • Printed in USA | 3 |

|