EC2-311 specifications

The Emerson EC2-311 is a sophisticated control solution designed for industrial automation and process management. Renowned for its reliability and performance, this controller is an ideal choice for various applications, including manufacturing, energy, and transportation. One of the EC2-311’s primary features is its advanced processing capabilities. Equipped with a powerful CPU, it offers rapid data processing and response times, which are crucial for maintaining operational efficiency in dynamic industrial environments.A key technology integrated into the EC2-311 is its embedded communication protocols. It supports multiple communication standards, including MODBUS, Ethernet/IP, and OPC UA, providing seamless integration with various devices and systems. This versatility not only enhances connectivity but also allows plant operators to monitor and control processes from remote locations, which is vital in today's global industrial landscape.

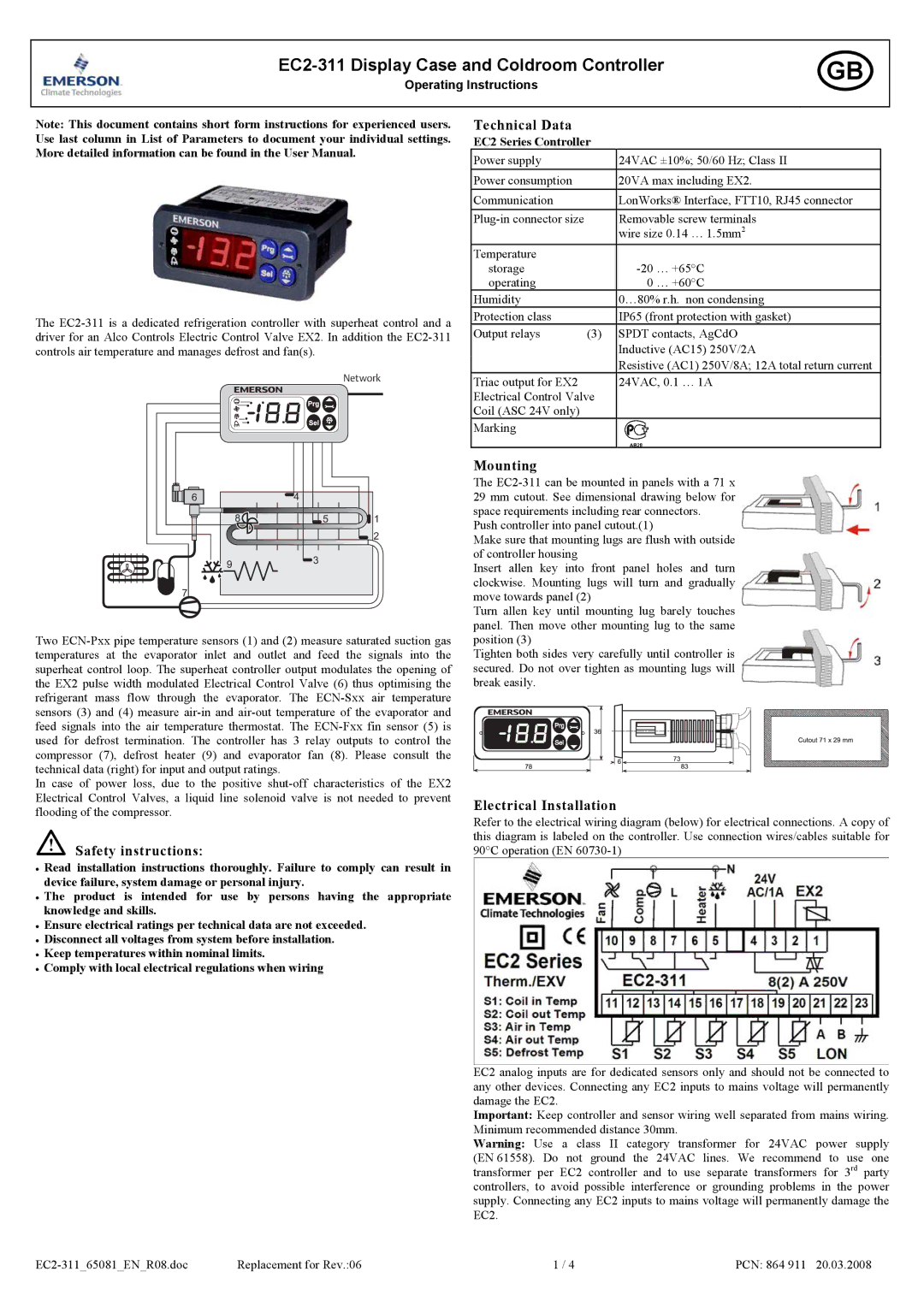

The EC2-311 also boasts an intuitive user interface. Its graphical user interface (GUI) facilitates easy navigation and real-time monitoring of system parameters. Users can customize dashboards to display critical data, making it easier to analyze trends and make informed decisions quickly. This feature enhances usability and reduces training time for personnel.

In terms of safety and reliability, the EC2-311 is built to withstand harsh industrial conditions. It is designed with robust housing and components that protect against environmental factors such as dust, moisture, and temperature variations. Additionally, it incorporates built-in fail-safes and redundancy features that ensure continuous operation, minimizing downtime and enhancing overall system reliability.

Another notable characteristic is its scalability. The EC2-311 can easily adapt to changes in production requirements, making it suitable for both small-scale operations and large manufacturing facilities. As businesses grow, the controller can be upgraded or expanded to accommodate more complex processes without requiring a complete system overhaul.

In summary, the Emerson EC2-311 stands out for its advanced processing capabilities, flexible communication options, user-friendly interface, durability, and scalability. With these features, it is well-equipped to meet the demands of modern industrial operations, ensuring efficiency, safety, and reliability in every application.