BP7284, Sturbrige, KF180 7/31/06 10:52 AM Page 5

![]()

![]() 2. Slide the four switch levers on the code switch to your choice of ON (up) or down positions. Use a

2. Slide the four switch levers on the code switch to your choice of ON (up) or down positions. Use a

![]()

![]() 3. In the receiver (Figure 1), slide the four switch levers to the same positions as set in the transmitter. Make sure the levers on both switches are in the same positions, otherwise the fan will not operate.

3. In the receiver (Figure 1), slide the four switch levers to the same positions as set in the transmitter. Make sure the levers on both switches are in the same positions, otherwise the fan will not operate.

![]()

![]() 4. Position the battery in the transmitter battery compartment and replace the battery cover.

4. Position the battery in the transmitter battery compartment and replace the battery cover.

CEILING FAN

PROCEDURES

Electrical Requirements

Your new ceiling fan will require a ground- ed electrical supply line of 120 volts AC, 60 Hz, 15 amp circuit.

!WARNING

Turning off wall switch is not suffi- cient. To avoid possible electrical shock, be sure electricity is turned off at the main fuse box before wiring. All wiring must be in accordance with National and Local codes and the ceil- ing fan must be properly grounded as a precaution against possible electri- cal shock.

How to Assemble Your Ceiling Fan

![]()

![]() 1. Remove the hanger ball by loosening the setscrew in the hanger ball until the ball falls freely down the downrod (Figure 2). Remove the pin from the downrod, then remove the hanger ball. Retain the pin and hanger ball for rein- stallation in step 5.

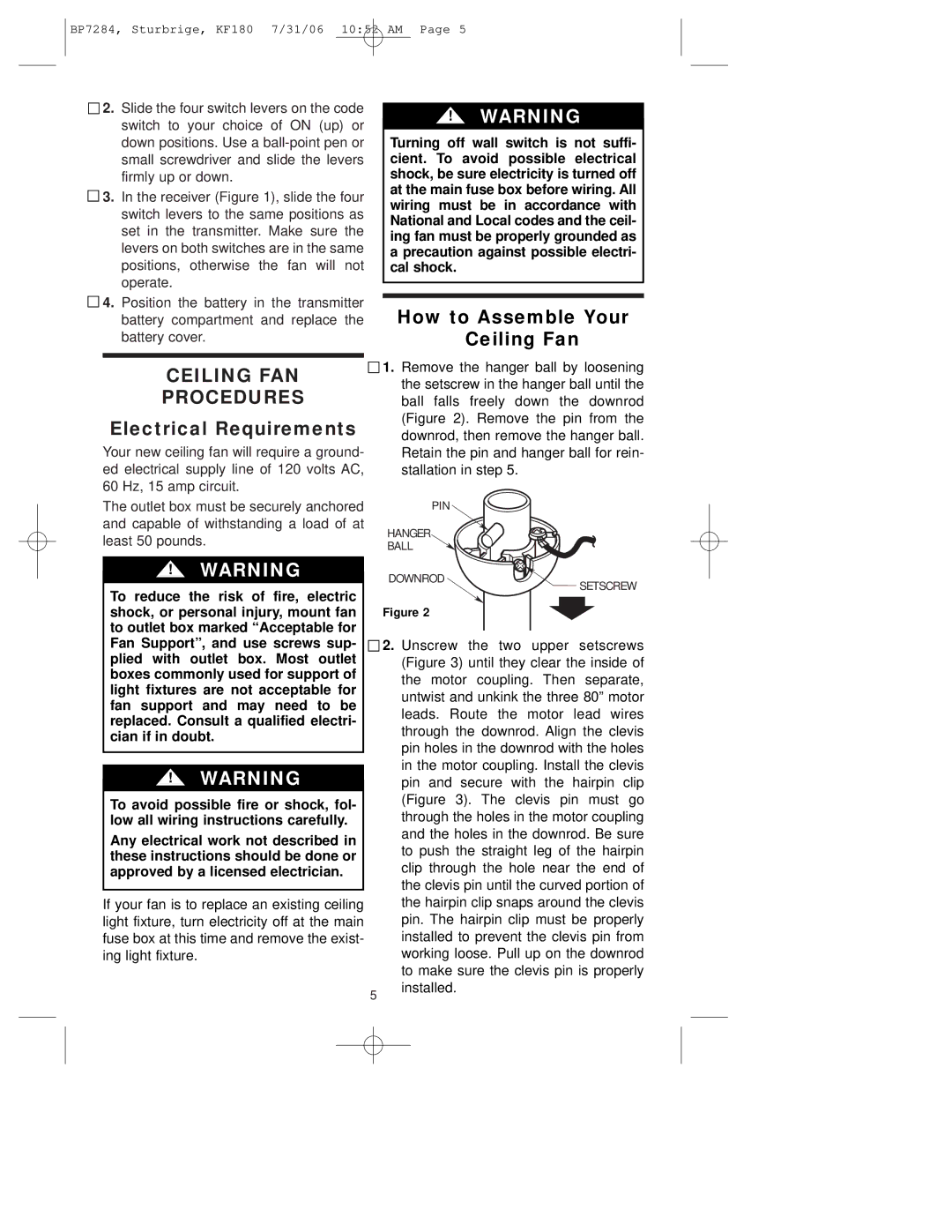

1. Remove the hanger ball by loosening the setscrew in the hanger ball until the ball falls freely down the downrod (Figure 2). Remove the pin from the downrod, then remove the hanger ball. Retain the pin and hanger ball for rein- stallation in step 5.

The outlet box must be securely anchored and capable of withstanding a load of at least 50 pounds.

!WARNING

To reduce the risk of fire, electric shock, or personal injury, mount fan to outlet box marked “Acceptable for Fan Support”, and use screws sup- plied with outlet box. Most outlet boxes commonly used for support of light fixtures are not acceptable for fan support and may need to be replaced. Consult a qualified electri- cian if in doubt.

!WARNING

To avoid possible fire or shock, fol- low all wiring instructions carefully.

Any electrical work not described in these instructions should be done or approved by a licensed electrician.

If your fan is to replace an existing ceiling light fixture, turn electricity off at the main fuse box at this time and remove the exist- ing light fixture.

5

PIN |

|

HANGER |

|

BALL |

|

DOWNROD | SETSCREW |

|

Figure 2

2. Unscrew the two upper setscrews (Figure 3) until they clear the inside of the motor coupling. Then separate, untwist and unkink the three 80” motor leads. Route the motor lead wires through the downrod. Align the clevis pin holes in the downrod with the holes in the motor coupling. Install the clevis pin and secure with the hairpin clip (Figure 3). The clevis pin must go through the holes in the motor coupling and the holes in the downrod. Be sure to push the straight leg of the hairpin clip through the hole near the end of the clevis pin until the curved portion of the hairpin clip snaps around the clevis pin. The hairpin clip must be properly installed to prevent the clevis pin from working loose. Pull up on the downrod to make sure the clevis pin is properly installed.