7. GAS LINE CONNECTION AND TESTING

WARNING: Only persons licensed to work with gas piping can make the gas connections to this appliance.

This appliance is equipped with a 3/8” stainless steel flex line from the valve. This line may be routed through the hole in the rear

of the pedestal, or on inserts, routed through the fire box sides. An adapter plate is available for installations that do not allow flex pipe through cabinetry.

NOTE: Consult your local authorities and in CAN. the

The appliance and its shutoff valves must be disconnected from the gas supply piping system during any pressure testing where the pressure exceeds 1/2 PSIG (3.45 kPa) or damage will occur to the valve.

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa).

Always check for gas leaks with a soap and water solution or an approved manner after completing required pressure tests.

ORIFICE SIZES, PRESSURES AND BTU'S

The efficiency rating of this appliance is a product thermal efficiency rating determined under continuous operating conditions and was

determined independently of any installed system. All models are equipped with a variable output gas control.

| NATURAL GAS | PROPANE | ||||

ORIFICES (Front / Rear) | #51 DMS / #49 DMS | #59 DMS / #56 DMS | ||||

Manifold Press: | 3.5" wc | / | 0.87 kPa | 10.0" wc | / | 2.49 kPa |

Min. Manifold Press: | 2.1” wc | / | 0.52 kPa | 6.2" wc | / | 1.54 kPa |

Max. Supply Press: | 7.0" wc | / | 1.74 kPa | 13.0" wc | / | 3.23 kPa |

Desired Supply Press: | 7.0" wc | / | 1.74 kPa | 11.0” wc | / | 2.74 kPa |

Min. Supply Press: | 5.0" wc | / | 1.25 kPa | 10.5" wc | / | 2.62 kPa |

Max. BTU/H Input: | 26,500 | / | 7.6 kW | 26,500 | / | 7.6 kW |

Min. BTU/H Input: | 21,000 | / | 6.15 kW | 21,000 | / 6.15 kW | |

MOBILE HOME Manifold Press: | 4.0" wc | / | 1.00 kPa | 10.0" wc | / | 2.49 kPa |

In Canada and the United States these appliances are certified for altitudes of

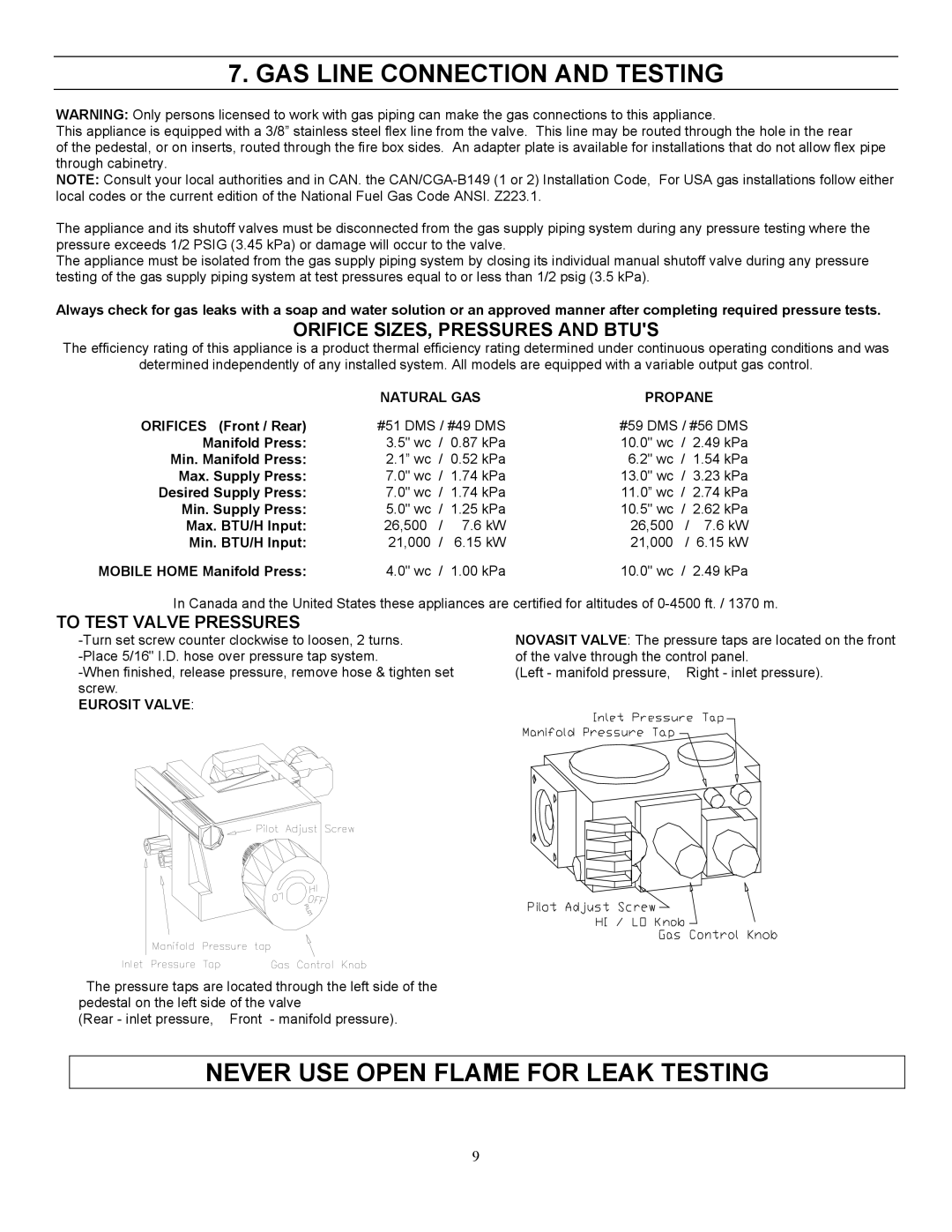

TO TEST VALVE PRESSURES

EUROSIT VALVE:

NOVASIT VALVE: The pressure taps are located on the front of the valve through the control panel.

(Left - manifold pressure, Right - inlet pressure).

The pressure taps are located through the left side of the pedestal on the left side of the valve

(Rear - inlet pressure, Front - manifold pressure).

NEVER USE OPEN FLAME FOR LEAK TESTING

9