Mini A specifications

The Enviro Mini A is a compact and efficient solution designed for a variety of environmental monitoring applications. As the demand for sustainable practices increases, the Enviro Mini A emerges as a key player in facilitating real-time data collection and analysis of environmental parameters.One of the main features of the Enviro Mini A is its advanced sensor technology. It is equipped with high-precision sensors that can monitor various environmental factors, including air quality, temperature, humidity, and atmospheric pressure. These sensors are designed to provide accurate readings, allowing users to make informed decisions based on reliable data.

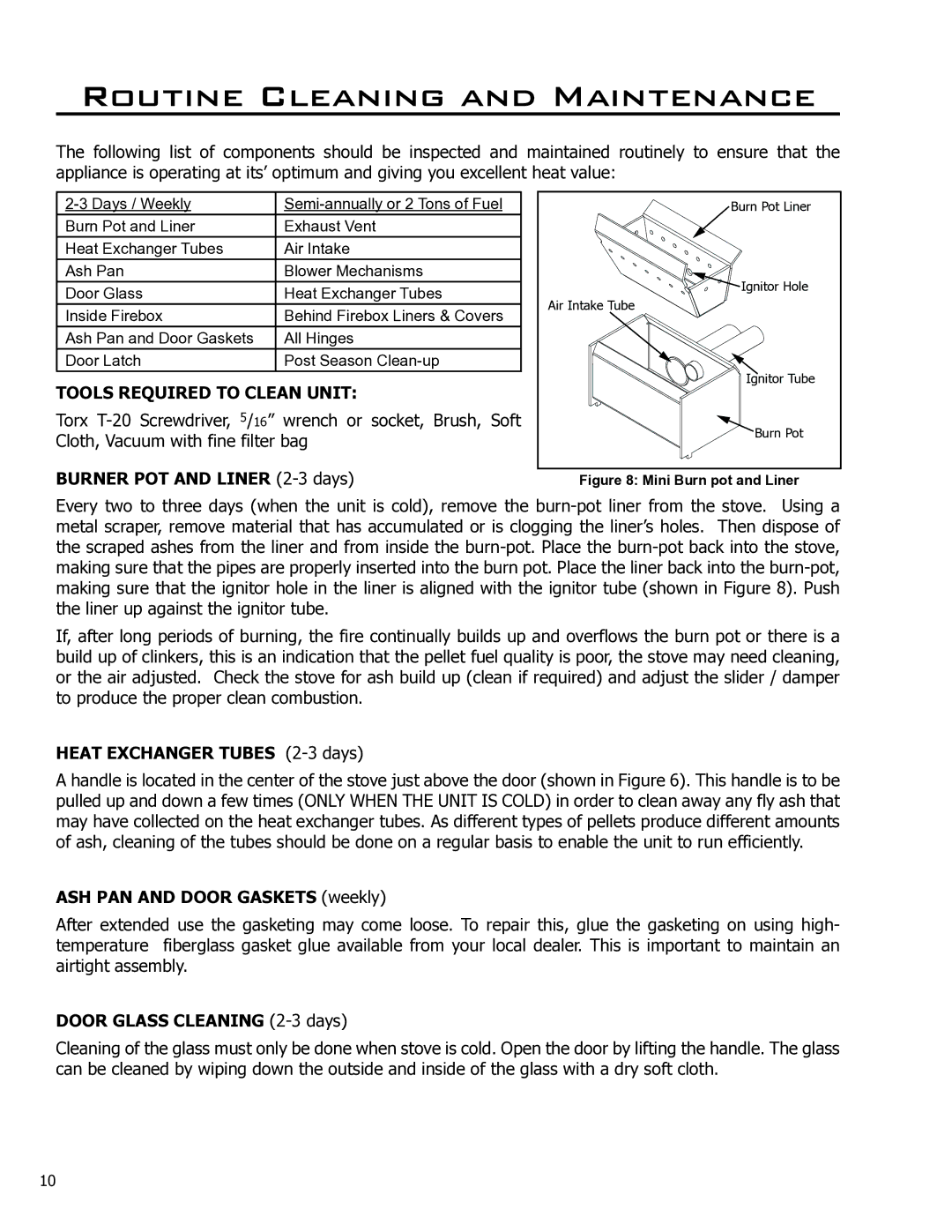

The design of the Enviro Mini A is another significant characteristic that sets it apart. Its compact size allows for easy installation in a variety of locations, from urban settings to remote areas. This versatility makes it suitable for deployments in schools, parks, industrial sites, and research facilities. The device can be mounted on poles, walls, or placed on flat surfaces, ensuring flexibility in how it can be utilized.

Connectivity is a critical aspect of the Enviro Mini A's functionality. The device is equipped with Wi-Fi and optional cellular connectivity, enabling seamless data transmission to cloud-based platforms for real-time analysis and monitoring. Users can access the data remotely via a user-friendly interface, allowing for quick responses to any environmental changes or alerts.

The Enviro Mini A also boasts a robust and weather-resistant design, making it capable of withstanding various environmental conditions. This durability ensures longevity and reliability, even in challenging outdoor settings. Furthermore, the device is energy-efficient, often powered by solar energy or a long-lasting battery, which reduces maintenance efforts and operational costs.

Incorporating advanced data analytics capabilities, the Enviro Mini A allows users to track trends over time, identify patterns, and generate reports that can assist in regulatory compliance and environmental assessments. Its integration with machine learning algorithms aids in predictive analytics, offering insights that can drive proactive environmental management strategies.

In summary, the Enviro Mini A is a state-of-the-art environmental monitoring device that combines advanced sensor technology with a robust design and connectivity features. Its versatility and analytical capabilities make it an invaluable tool for anyone looking to monitor and improve environmental conditions effectively.