Cooler Installation

![]() CAUTION: Make sure that the mounting surface is strong enough to support the operating weight of the cooler when in use. (For operating weight, see Specification Table.)

CAUTION: Make sure that the mounting surface is strong enough to support the operating weight of the cooler when in use. (For operating weight, see Specification Table.)

![]() CAUTION: Never start cooler until installation is complete and unit has been tested for rigidity.

CAUTION: Never start cooler until installation is complete and unit has been tested for rigidity.

![]() CAUTION: Do not screw or drill within 5 inches of the bottom of the wet module. You could puncture the reservoir.

CAUTION: Do not screw or drill within 5 inches of the bottom of the wet module. You could puncture the reservoir.

![]() CAUTION: If the unit is supported with legs at each corner, the middle of the unit where the two sec-

CAUTION: If the unit is supported with legs at each corner, the middle of the unit where the two sec-

tions join must be supported as well.

| Wet | |

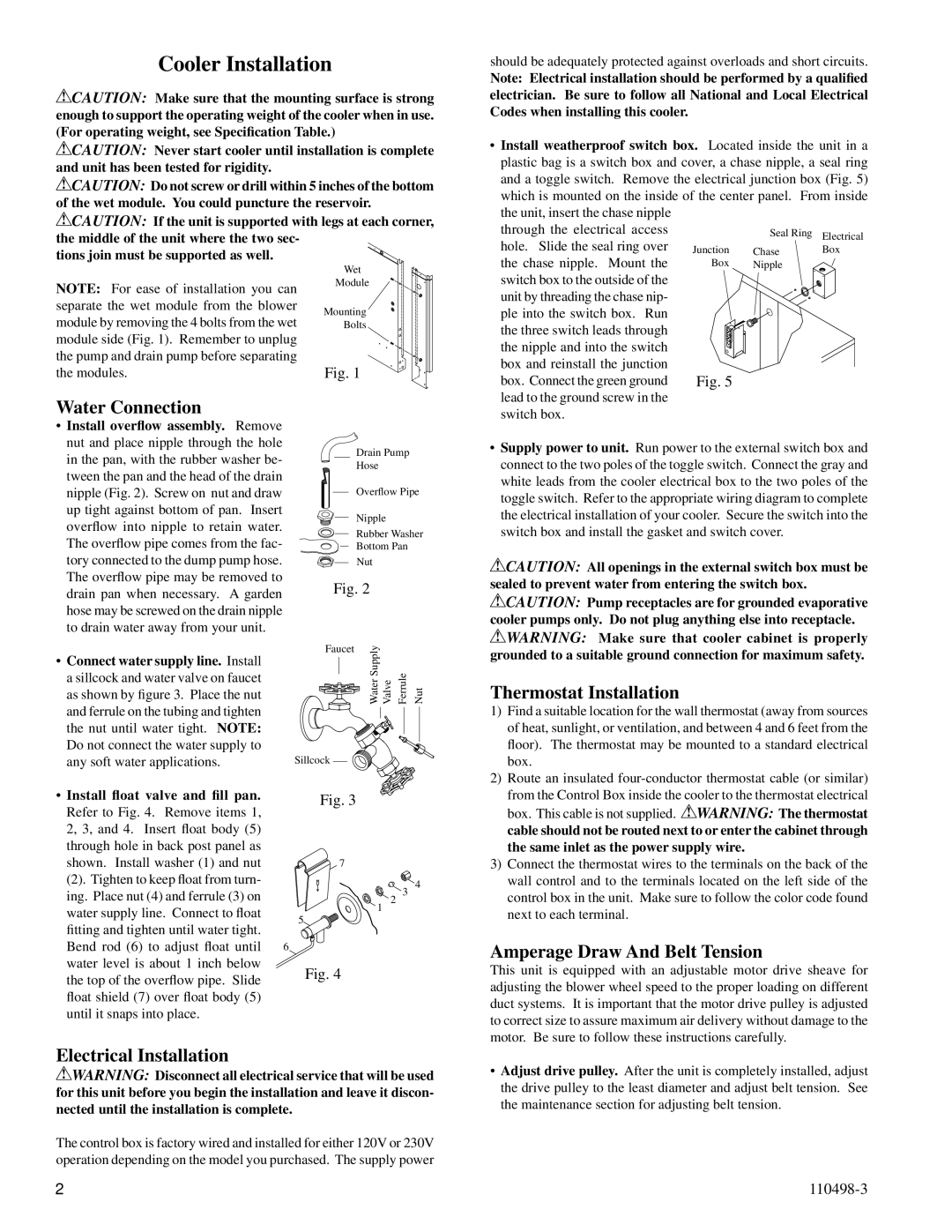

NOTE: For ease of installation you can | Module | |

separate the wet module from the blower | Mounting | |

module by removing the 4 bolts from the wet | ||

Bolts | ||

module side (Fig. 1). Remember to unplug |

| |

the pump and drain pump before separating | Fig. 1 | |

the modules. |

should be adequately protected against overloads and short circuits.

Note: Electrical installation should be performed by a qualified electrician. Be sure to follow all National and Local Electrical Codes when installing this cooler.

•Install weatherproof switch box. Located inside the unit in a plastic bag is a switch box and cover, a chase nipple, a seal ring and a toggle switch. Remove the electrical junction box (Fig. 5) which is mounted on the inside of the center panel. From inside the unit, insert the chase nipple

through the electrical access |

| Seal Ring | Electrical |

hole. Slide the seal ring over |

| ||

Junction | Chase | Box | |

the chase nipple. Mount the | Box | Nipple |

|

switch box to the outside of the |

|

|

|

unit by threading the chase nip- |

|

|

|

ple into the switch box. Run |

|

|

|

the three switch leads through |

|

|

|

the nipple and into the switch |

|

|

|

box and reinstall the junction | Fig. 5 |

|

|

box. Connect the green ground |

|

| |

lead to the ground screw in the |

|

|

|

Water Connection

•Install overflow assembly. Remove nut and place nipple through the hole in the pan, with the rubber washer be- tween the pan and the head of the drain nipple (Fig. 2). Screw on nut and draw up tight against bottom of pan. Insert overflow into nipple to retain water. The overflow pipe comes from the fac- tory connected to the dump pump hose. The overflow pipe may be removed to drain pan when necessary. A garden hose may be screwed on the drain nipple to drain water away from your unit.

Drain Pump

Hose

Overflow Pipe

Nipple

Rubber Washer

Bottom Pan

Nut

Fig. 2

switch box. |

•Supply power to unit. Run power to the external switch box and connect to the two poles of the toggle switch. Connect the gray and white leads from the cooler electrical box to the two poles of the toggle switch. Refer to the appropriate wiring diagram to complete the electrical installation of your cooler. Secure the switch into the switch box and install the gasket and switch cover.

![]() CAUTION: All openings in the external switch box must be sealed to prevent water from entering the switch box.

CAUTION: All openings in the external switch box must be sealed to prevent water from entering the switch box.

![]() CAUTION: Pump receptacles are for grounded evaporative cooler pumps only. Do not plug anything else into receptacle.

CAUTION: Pump receptacles are for grounded evaporative cooler pumps only. Do not plug anything else into receptacle.

![]() WARNING: Make sure that cooler cabinet is properly

WARNING: Make sure that cooler cabinet is properly

• Connect water supply line. Install |

a sillcock and water valve on faucet |

as shown by figure 3. Place the nut |

and ferrule on the tubing and tighten |

the nut until water tight. NOTE: |

Do not connect the water supply to |

Faucet

SupplyWaterValveFerruleNut

grounded to a suitable ground connection for maximum safety.

Thermostat Installation

1) Find a suitable location for the wall thermostat (away from sources |

of heat, sunlight, or ventilation, and between 4 and 6 feet from the |

floor). The thermostat may be mounted to a standard electrical |

any soft water applications. |

• Install float valve and fill pan. |

Refer to Fig. 4. Remove items 1, |

2, 3, and 4. Insert float body (5) |

through hole in back post panel as |

shown. Install washer (1) and nut |

(2). Tighten to keep float from turn- |

ing. Place nut (4) and ferrule (3) on |

water supply line. Connect to float |

fitting and tighten until water tight. |

Bend rod (6) to adjust float until |

water level is about 1 inch below |

the top of the overflow pipe. Slide |

float shield (7) over float body (5) |

until it snaps into place. |

Sillcock

Fig. 3

7

1

5

6

Fig. 4

2

3 4

box. |

2) Route an insulated |

from the Control Box inside the cooler to the thermostat electrical |

box. This cable is not supplied. WARNING: The thermostat |

cable should not be routed next to or enter the cabinet through |

the same inlet as the power supply wire. |

3) Connect the thermostat wires to the terminals on the back of the |

wall control and to the terminals located on the left side of the |

control box in the unit. Make sure to follow the color code found |

next to each terminal. |

Amperage Draw And Belt Tension

This unit is equipped with an adjustable motor drive sheave for adjusting the blower wheel speed to the proper loading on different duct systems. It is important that the motor drive pulley is adjusted to correct size to assure maximum air delivery without damage to the motor. Be sure to follow these instructions carefully.

Electrical Installation

![]() WARNING: Disconnect all electrical service that will be used for this unit before you begin the installation and leave it discon- nected until the installation is complete.

WARNING: Disconnect all electrical service that will be used for this unit before you begin the installation and leave it discon- nected until the installation is complete.

The control box is factory wired and installed for either 120V or 230V operation depending on the model you purchased. The supply power

•Adjust drive pulley. After the unit is completely installed, adjust the drive pulley to the least diameter and adjust belt tension. See the maintenance section for adjusting belt tension.

2 |

|