Maintenance

Check Mower Blades

Service Interval: Before each use or daily

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Lift deck and secure in raised position as stated in the Clean Grass

3.Inspect blades and sharpen or replace as required.

4.Reinstall the blades (if they were removed) in the following order:

A.Install bushing through blade with bushing flange on bottom (grass) side of blade.

Figure 11

1.Install bushing in blade prior to installing bushing in spindle.

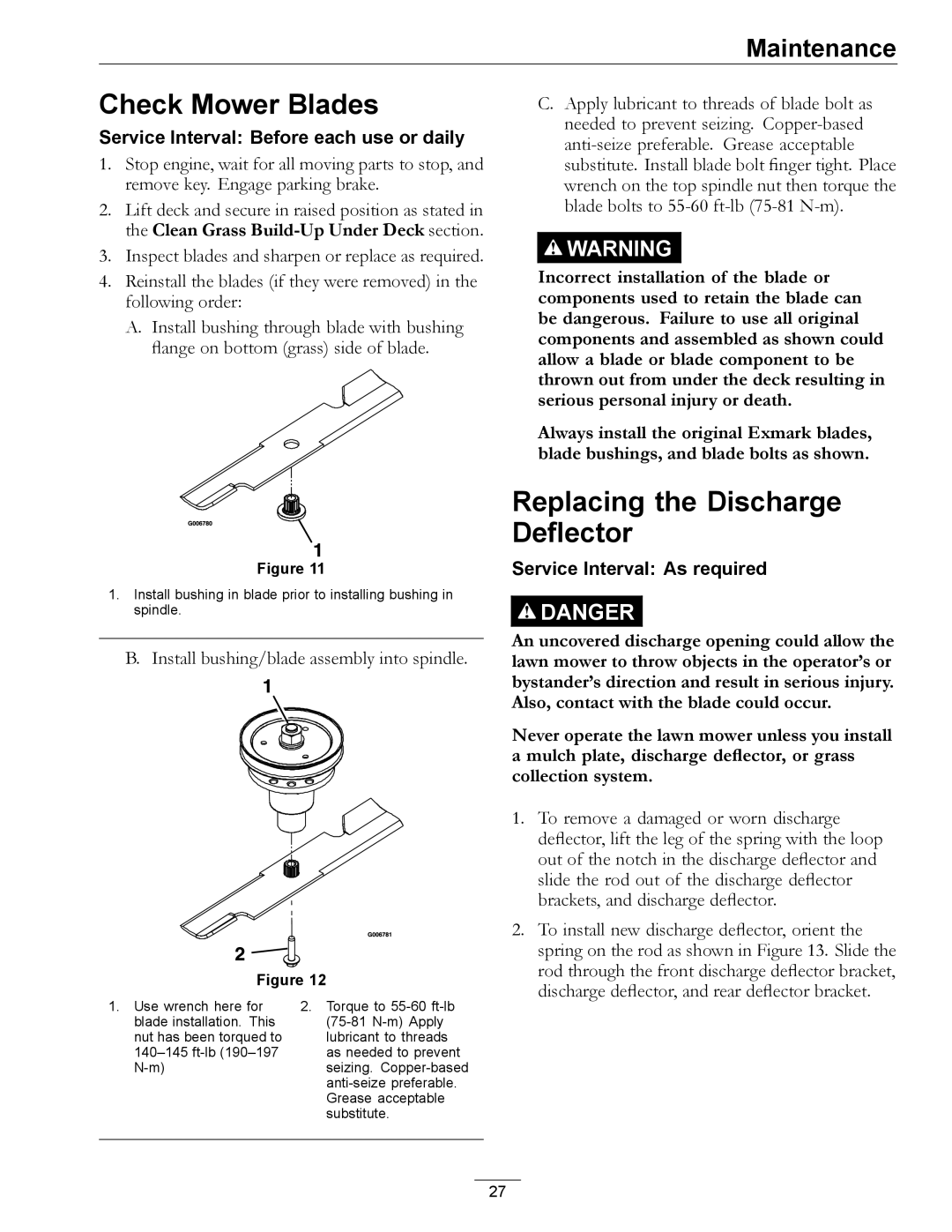

B.Install bushing/blade assembly into spindle.

Figure 12

C.Apply lubricant to threads of blade bolt as needed to prevent seizing.

![]()

![]() WARNING

WARNING

Incorrect installation of the blade or components used to retain the blade can be dangerous. Failure to use all original components and assembled as shown could allow a blade or blade component to be thrown out from under the deck resulting in serious personal injury or death.

Always install the original Exmark blades, blade bushings, and blade bolts as shown.

Replacing the Discharge Deflector

Service Interval: As required

![]()

![]() DANGER

DANGER

An uncovered discharge opening could allow the lawn mower to throw objects in the operator’s or bystander’s direction and result in serious injury. Also, contact with the blade could occur.

Never operate the lawn mower unless you install a mulch plate, discharge deflector, or grass collection system.

1.To remove a damaged or worn discharge deflector, lift the leg of the spring with the loop out of the notch in the discharge deflector and slide the rod out of the discharge deflector brackets, and discharge deflector.

2.To install new discharge deflector, orient the spring on the rod as shown in Figure 13. Slide the rod through the front discharge deflector bracket, discharge deflector, and rear deflector bracket.

1.Use wrench here for blade installation. This nut has been torqued to

2.Torque to

27