Maintenance

Maintenance Service | Maintenance Procedure | |

Interval | ||

| ||

|

| |

| • Charge the battery and disconnect the battery cables. | |

Before storage | • Perform all maintenance procedures before storage. | |

| • Paint any chipped surfaces. | |

Monthly | • Check the battery charge. | |

|

|

Important: Refer to your Engine Operator’s Manual for additional maintenance procedures.

Premaintenance

Procedures

Raising the Seat

Make sure the motion control levers are locked in the neutral position. Lift the seat forward until the lanyard is tight. The following components can be accessed by raising the seat:

•Auxiliary 12V Plug (12V accessory up to 15 amp)

•Fuses

•Battery cables

Accessing the Battery

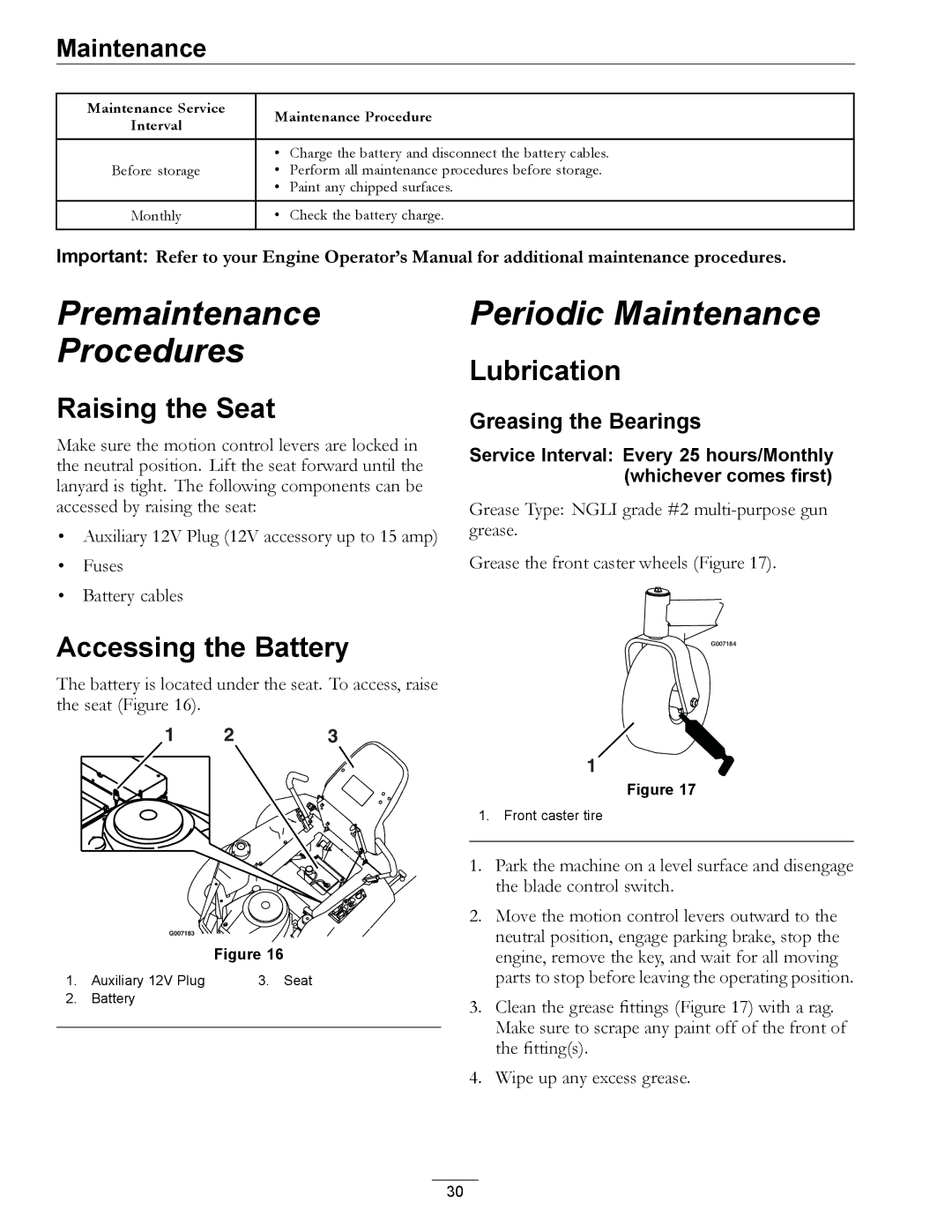

The battery is located under the seat. To access, raise the seat (Figure 16).

Periodic Maintenance

Lubrication

Greasing the Bearings

Service Interval: Every 25 hours/Monthly (whichever comes first)

Grease Type: NGLI grade #2

Grease the front caster wheels (Figure 17).

G007184

Figure 16

1. | Auxiliary 12V Plug | 3. Seat |

2. | Battery |

|

|

|

|

1

Figure 17

1.Front caster tire

1.Park the machine on a level surface and disengage the blade control switch.

2.Move the motion control levers outward to the neutral position, engage parking brake, stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

3.Clean the grease fittings (Figure 17) with a rag. Make sure to scrape any paint off of the front of the fitting(s).

4.Wipe up any excess grease.

30